At their core, composite toe and steel toe safety shoes offer certified protection against workplace hazards, but they achieve it with fundamentally different materials. While both must meet the same minimum safety standards, the choice between them hinges on a critical trade-off: steel's raw strength versus composite's lighter weight, insulation, and non-metallic properties.

The question isn't which toe cap is "better," but rather which is better for your specific environment. Steel prioritizes ultimate durability and impact resistance, while composite prioritizes lightweight comfort and versatility in varied conditions.

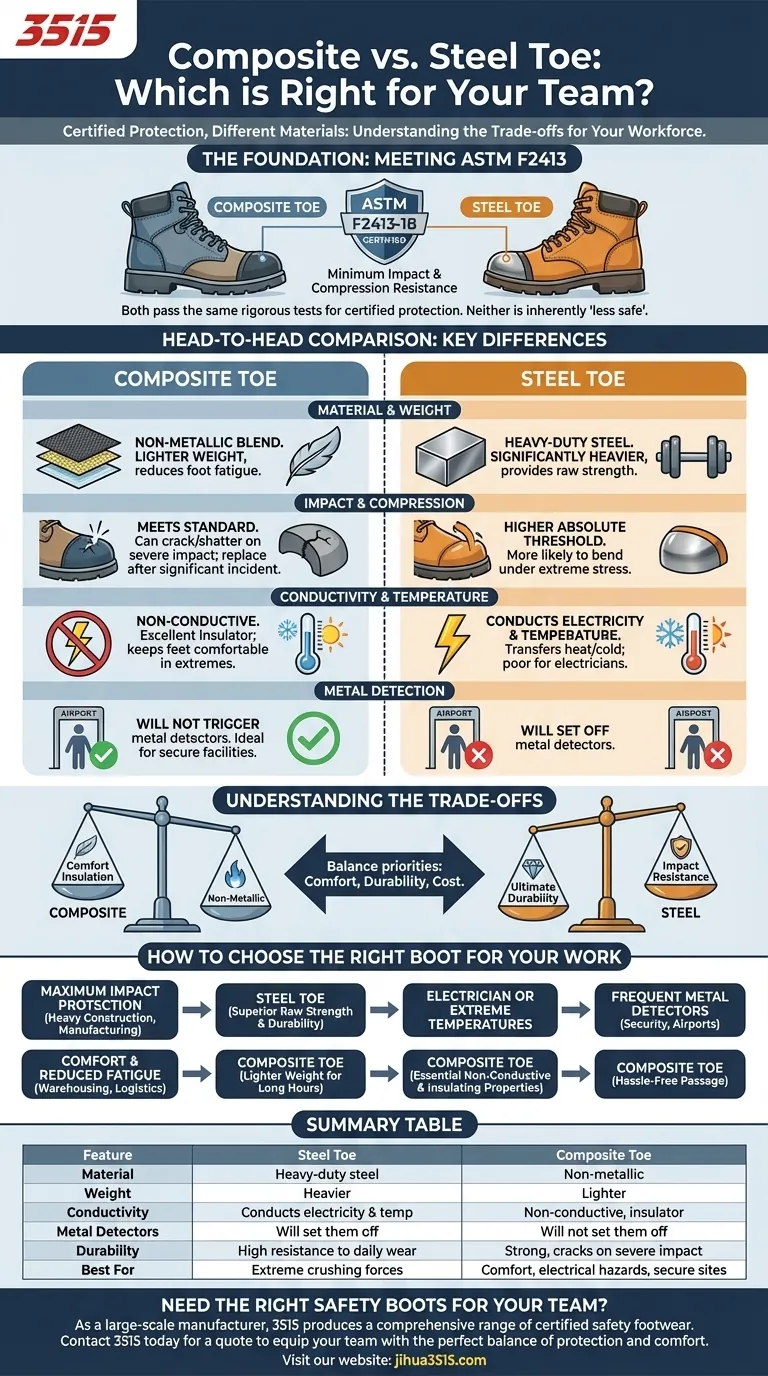

The Foundation: Meeting the Same Safety Standard

Before comparing differences, it's crucial to understand what makes both options viable safety equipment.

What the ASTM F2413 Standard Means

Both steel and composite toe boots sold as safety footwear in the United States must meet standards set by ASTM International, specifically ASTM F2413-18.

This standard specifies minimum performance requirements for impact and compression resistance. To be certified, a boot must protect the wearer's toes from a specific level of force.

The Reality of Certified Protection

This means that a certified composite toe boot has passed the exact same rigorous tests as a certified steel toe boot. For the defined level of protection, one is not inherently "less safe" than the other.

Key Differences: A Head-to-Head Comparison

The functional differences between steel and composite materials are what should guide your decision.

Material and Weight

A steel toe cap is made of heavy-duty steel. This makes it strong but also significantly heavier.

A composite toe cap is made from a blend of non-metallic materials like Kevlar, carbon fiber, fiberglass, or even plastic. This makes them considerably lighter, reducing foot fatigue over a long day.

Impact and Compression Resistance

While both meet the ASTM standard, steel offers a higher absolute threshold for protection against extreme crushing and impact forces. It is more likely to bend under extreme stress.

Composite materials provide the required protection but can crack or shatter upon a single severe impact. After any significant incident, a composite toe boot should be replaced.

Conductivity and Temperature

Steel is a conductor. It will readily transfer cold in freezing weather and heat in hot conditions, and it conducts electricity, making it a poor choice for electricians.

Composite materials are non-conductive. They are excellent insulators, keeping your feet more comfortable in extreme temperatures and providing essential protection from electrical hazards.

Metal Detection

Because they are made of steel, steel toe boots will set off metal detectors.

Composite toe boots are non-metallic and will not trigger metal detectors, making them ideal for workers in airports, nuclear plants, or other secure facilities.

Understanding the Trade-offs

Choosing between steel and composite involves balancing competing priorities like comfort, durability, and cost.

The Comfort Factor

The lighter weight of composite toe boots is a primary driver of comfort, especially during long shifts with constant walking. Their insulating properties also add to comfort in very hot or cold environments.

The Durability Question

Steel is exceptionally durable and can withstand minor bumps and scrapes without compromising its integrity. A dent in a steel toe is a visible sign of damage.

Composite materials are strong, but their durability is focused on resisting a single major impact. They are not as resilient to the daily wear and tear of a heavy industrial site.

The Cost Implication

Generally, the advanced materials used in composite toe boots make them more expensive than their traditional steel toe counterparts.

How to Choose the Right Boot for Your Work

Evaluate your daily tasks and environment to make an informed decision.

- If your primary focus is maximum impact protection (heavy construction, logging, manufacturing): Steel toe is the superior choice for its raw strength and proven durability against extreme crushing forces.

- If your primary focus is comfort and reducing fatigue (warehousing, logistics, trade work): The lighter weight of a composite toe can make a significant difference over long hours on your feet.

- If you are an electrician or work in extreme temperatures: Composite toe is the only appropriate choice due to its essential non-conductive and insulating properties.

- If you frequently pass through metal detectors (airport ground crews, security): Composite toe is the clear winner, saving you the daily hassle of removing your footwear.

Ultimately, the best choice is the one that aligns perfectly with the specific demands and hazards of your daily work.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Material | Heavy-duty steel | Non-metallic (Kevlar, fiberglass, etc.) |

| Weight | Heavier | Lighter |

| Conductivity | Conducts electricity & temperature | Non-conductive, excellent insulator |

| Metal Detectors | Will set them off | Will not set them off |

| Durability | High resistance to daily wear & tear | Strong, but can crack on severe impact |

| Best For | Extreme crushing forces, heavy industry | Comfort, electrical hazards, extreme temps, secure sites |

Need the Right Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your workforce requires the ultimate durability of steel toe or the lightweight comfort and insulation of composite toe, we have the production capabilities and expertise to meet your exact needs.

Let us help you equip your team with the perfect balance of protection and comfort.

Contact 3515 today for a quote and let's discuss your specific requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health