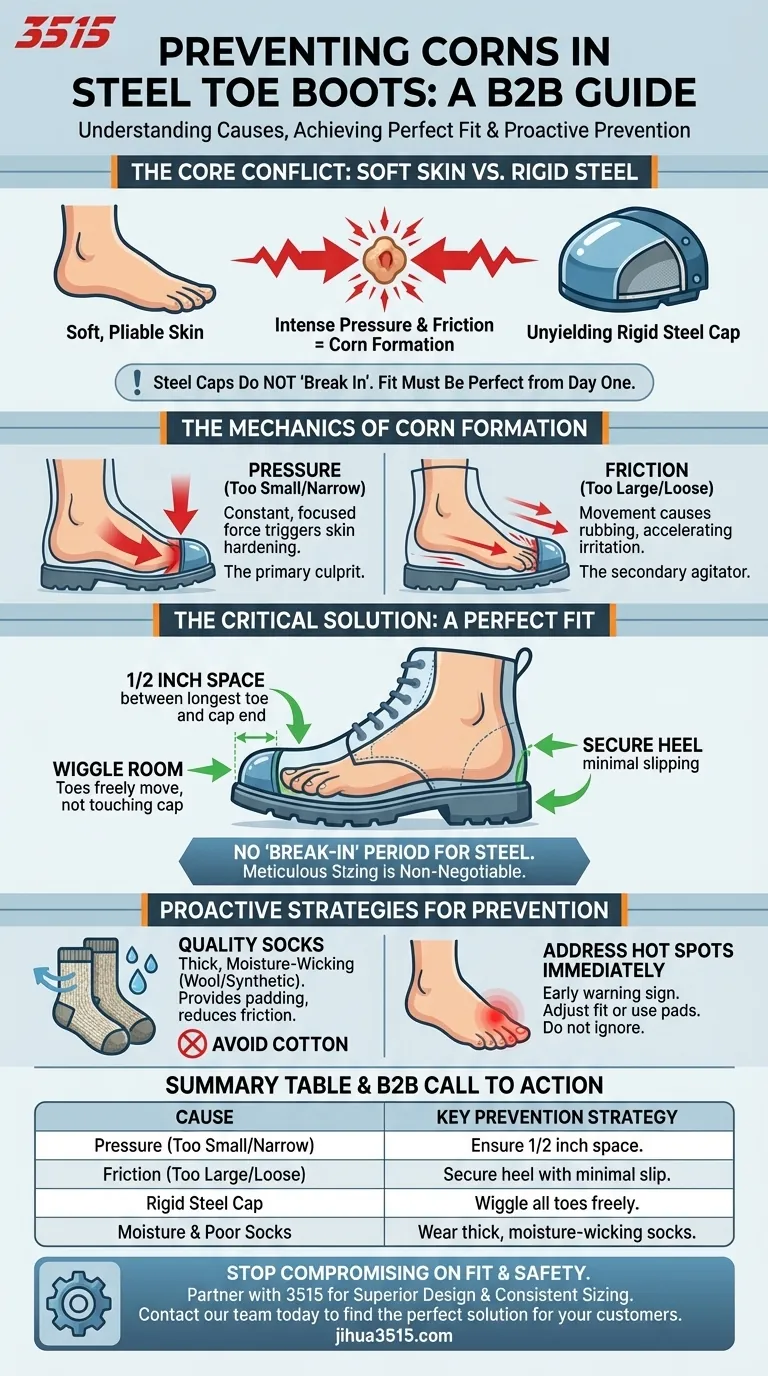

At its core, the formation of corns from steel toe boots is a direct result of a fundamental conflict: the soft, pliable skin of your toes versus the unyielding rigidity of the steel cap. They are caused by intense, localized pressure and friction, which happens when the boot is improperly fitted, forcing your toes against the hard interior surface.

The central issue is not the steel toe itself, but the lack of a perfect fit. Unlike leather, steel does not stretch or "break in," meaning any pressure points or rubbing you feel from the cap on day one will persist and inevitably lead to skin problems like corns.

The Mechanics of Corn Formation

To prevent a problem, you must first understand its cause. A corn is not a random affliction; it is your skin's defensive response to repeated mechanical stress.

Pressure: The Primary Culprit

The primary job of the steel cap is to resist impact, which means it is completely rigid. When a boot is too short or the toe box is too narrow for your foot, your toes are pressed directly against this unforgiving surface.

This constant, focused pressure is the main trigger for the skin to thicken and harden in a concentrated spot, forming the core of the corn.

Friction: The Secondary Agitator

If the boot is too large or loose, your foot will slide forward with each step. This movement creates friction as your toes repeatedly rub against the steel cap's inner edge.

This rubbing irritates the skin, compounding the effects of the pressure and accelerating the formation of a painful, hardened layer.

The Critical Importance of a Proper Fit

With safety footwear, a "good enough" fit is a recipe for chronic pain. The success of wearing steel toe boots comfortably rests almost entirely on achieving the correct fit from the very beginning.

Why the Fit Must Be Perfect

Leather and other upper materials will stretch and conform to your foot over time. The steel toe cap will not.

There is no "break-in" period for the steel cap. If it presses or rubs against your toes in the store, it will continue to do so indefinitely.

Key Indicators of a Correct Fit

When trying on boots, you must be meticulous. There should be about a half-inch of space between your longest toe and the end of the boot.

You must be able to freely wiggle all of your toes without them touching the steel cap. Your heel should feel secure with minimal slipping, as excessive movement causes the friction mentioned earlier.

Proactive Strategies for Prevention

Beyond selecting the right size, several other factors can help you avoid corns and other foot-related issues.

The Role of Quality Socks

Never underestimate the importance of your socks. They are the interface between your skin and the boot.

Thick, moisture-wicking socks made of wool or synthetic blends provide crucial padding. They reduce friction and keep your skin dry, making it more resilient to pressure. Cotton socks should be avoided as they retain moisture.

Address Hot Spots Immediately

During the first few days of wearing new boots, pay close attention to any "hot spots"—areas of redness or soreness on your toes.

This is the earliest warning sign that a corn is developing. If you feel a spot of persistent pressure from the steel cap, you must address the fit. The problem will not resolve itself.

Making the Right Choice for Your Goal

Your approach to selecting and wearing steel toe boots determines whether they are a tool for safety or a source of pain.

- If your primary focus is buying new boots: Prioritize a roomy toe box that allows for natural toe splay and movement, and always shop at the end of the day when your feet are slightly swollen.

- If your primary focus is breaking in new boots: Pay attention to discomfort. Pressure from the leather can be managed, but direct, hard pressure from the steel cap is a sign of a poor fit that will not improve.

- If your primary focus is treating existing corns: Immediately stop wearing the offending boots until you can solve the fit issue, and use protective corn pads to relieve pressure while the skin heals.

Ultimately, ensuring a proper fit is the only reliable way to make protective footwear work for you, not against you.

Summary Table:

| Cause of Corns | Key Prevention Strategy |

|---|---|

| Pressure from a too-short/narrow boot | Ensure a half-inch of space in front of your longest toe |

| Friction from a too-loose boot | Your heel should be secure with minimal slippage |

| Rigid Steel Cap that does not 'break in' | You must be able to wiggle all toes without touching the cap |

| Moisture & Poor Socks | Wear thick, moisture-wicking socks, not cotton |

Stop compromising on fit and safety. As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality steel toe boots for distributors, brand owners, and bulk clients. Our expertise ensures superior design and consistent sizing, helping you provide footwear that protects without causing pain. Contact our team today to discuss your footwear needs and find the perfect solution for your customers.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

People Also Ask

- How do steel toe boots compare to composite toe boots in terms of protection? A Guide to Maximum Safety & Comfort

- What are steel toe boots and how are they designed? Essential Guide to Industrial Footwear Safety

- What are the benefits of wearing steel toe boots? Maximum Impact Protection & Durability

- What are the key features of steel toe shoes? Maximum Impact Protection for Industrial Work

- What are the advantages of steel toe shoes? Unmatched Protection for Industrial Work

- What are some alternatives to steel toe shoes? Explore Lighter, Safer Options for Your Workforce

- Is there a downside to steel toe boots? Weighing Protection Against Daily Comfort

- What are the advantages of alloy toe work shoes? Lighter Weight, Superior Comfort