Traditional leather conditioners were ineffective for firefighter boots because their core ingredients—like mink oil, pine tar, and certain chemicals—fundamentally misunderstood the needs of structural safety leather. Instead of preserving the material, they sealed its pores and chemically broke down its internal fibers. This dual-action attack led to trapped body acids causing internal rot and a weakened structure that resulted in premature cracking.

The essential failure of traditional conditioners was treating firefighter boots like casual footwear. They focused on creating a soft, sealed surface, whereas a boot designed for extreme duty requires conditioners that maintain fiber strength and allow the leather to breathe, preventing its self-destruction from the inside out.

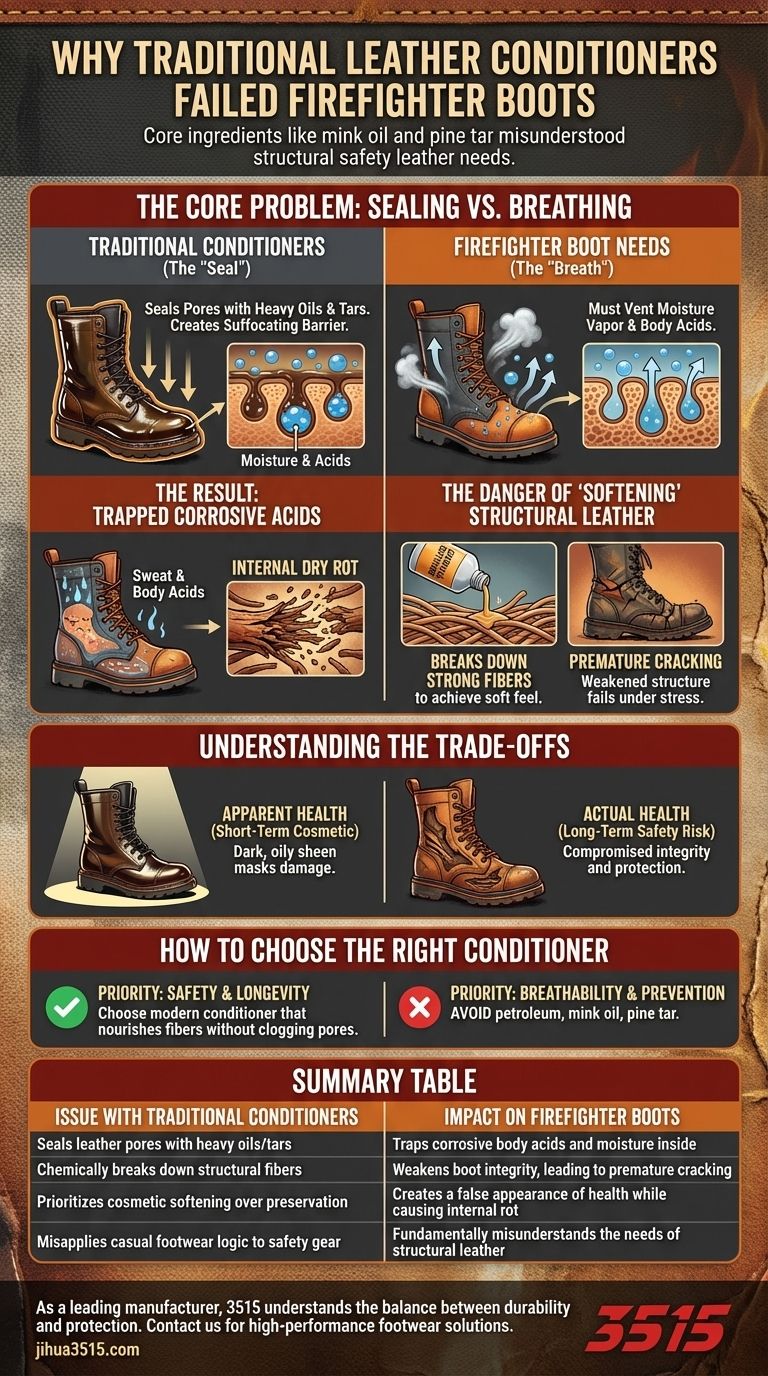

The Core Problem: Sealing vs. Breathing

The primary role of leather in a firefighter's boot is to provide a durable yet breathable barrier. Traditional conditioners created an impermeable seal that trapped moisture and acids, leading to catastrophic failure.

The Myth of a "Sealed" Barrier

Leather is a natural skin, full of microscopic pores essential for venting moisture vapor. Traditional products containing heavy oils and tars clog these pores completely. They create a suffocating barrier on the leather's surface.

Trapping Corrosive Body Acids

Firefighting is physically demanding work that produces significant sweat. This moisture contains body acids that must be allowed to escape.

When a conditioner seals the boot's leather, these acids become trapped. They concentrate within the leather's structure, creating a highly corrosive internal environment.

The Result: Dry Rot from the Inside Out

This trapped mixture of acidic moisture relentlessly attacks the leather's protein fibers from within. This chemical decay is known as dry rot. The leather loses its integrity and becomes brittle, even if the exterior appears conditioned.

The Danger of "Softening" Structural Leather

The second major failure was the very goal of "softening" the leather. While desirable for a dress shoe, this process is destructive to a boot that must provide structural support and protection.

How Traditional Softeners Work

Many traditional conditioners achieve a soft feel by using chemicals that actively break down the dense, interwoven protein fibers that give leather its tensile strength and rigidity.

Weakening the Boot's Foundation

This chemical breakdown compromises the boot's essential structure. The leather loses its ability to support the ankle, resist punctures, and hold its shape under the immense stress of a fire scene.

The Consequence: Premature Cracking

A boot with a weakened fiber structure cannot withstand the constant flexing of walking, climbing, and kneeling. The damaged fibers separate and tear easily, leading to deep cracks forming at stress points long before the end of the boot's expected service life.

Understanding the Trade-offs: Apparent vs. Actual Health

The appeal of traditional products was that they provided a quick cosmetic effect, but this masked the severe internal damage they were causing.

The Lure of a Dark, Oily Sheen

Applying a heavy, oil-based conditioner often results in an immediate dark, rich shine. This gives the appearance of healthy, well-maintained leather.

Short-Term Aesthetics vs. Long-Term Safety

This cosmetic benefit came at the cost of the boot's structural integrity and safety. The trade-off was a boot that looked good for a short time but was actively being weakened with every application, putting the user at risk.

How to Choose the Right Conditioner

Proper boot maintenance requires selecting a product designed for the unique demands of fire-tanned leather, prioritizing preservation over cosmetic softening.

- If your primary focus is safety and longevity: Choose a modern conditioner specifically formulated to nourish leather fibers without clogging its pores.

- If your goal is to maintain breathability and prevent internal rot: Avoid any product that lists petroleum, mink oil, or pine tar as a primary ingredient, as these are the main sealing agents.

Properly maintaining your boots is not about appearance; it is a critical component of your personal safety equipment.

Summary Table:

| Issue with Traditional Conditioners | Impact on Firefighter Boots |

|---|---|

| Seals leather pores with heavy oils/tars | Traps corrosive body acids and moisture inside |

| Chemically breaks down structural fibers | Weakens boot integrity, leading to premature cracking |

| Prioritizes cosmetic softening over preservation | Creates a false appearance of health while causing internal rot |

| Misapplies casual footwear logic to safety gear | Fundamentally misunderstands the needs of structural leather |

As a leading manufacturer of professional safety footwear, 3515 understands the critical balance between durability and protection. We produce high-performance boots for distributors, brand owners, and bulk clients, engineered to withstand extreme conditions without compromising on safety. Don't let improper maintenance shorten the life of your essential gear. Contact our experts today to discover how our comprehensive range of footwear solutions can meet your specific needs for reliability and longevity.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

People Also Ask

- What is the overall importance of choosing the right work boots? Protect Your Safety and Health

- What are some tips for measuring and fitting work boots correctly? Ensure All-Day Comfort and Safety

- What is the recommended method for cleaning boot leather? A Step-by-Step Guide to Preserve Your Boots

- What are the signs that wildland firefighter boots need repair or replacement? A Guide to Critical Safety Checks

- How much water pressure can waterproof boots withstand? A Guide to Waterproof Integrity

- What are the differences between fire boots and regular work boots? A Guide to Life-Saving Footwear

- How can engineer boots be styled in fashion? Master the Art of Rugged Elegance

- When should heavy duty work boots be replaced? A Guide to Maximize Safety and Value