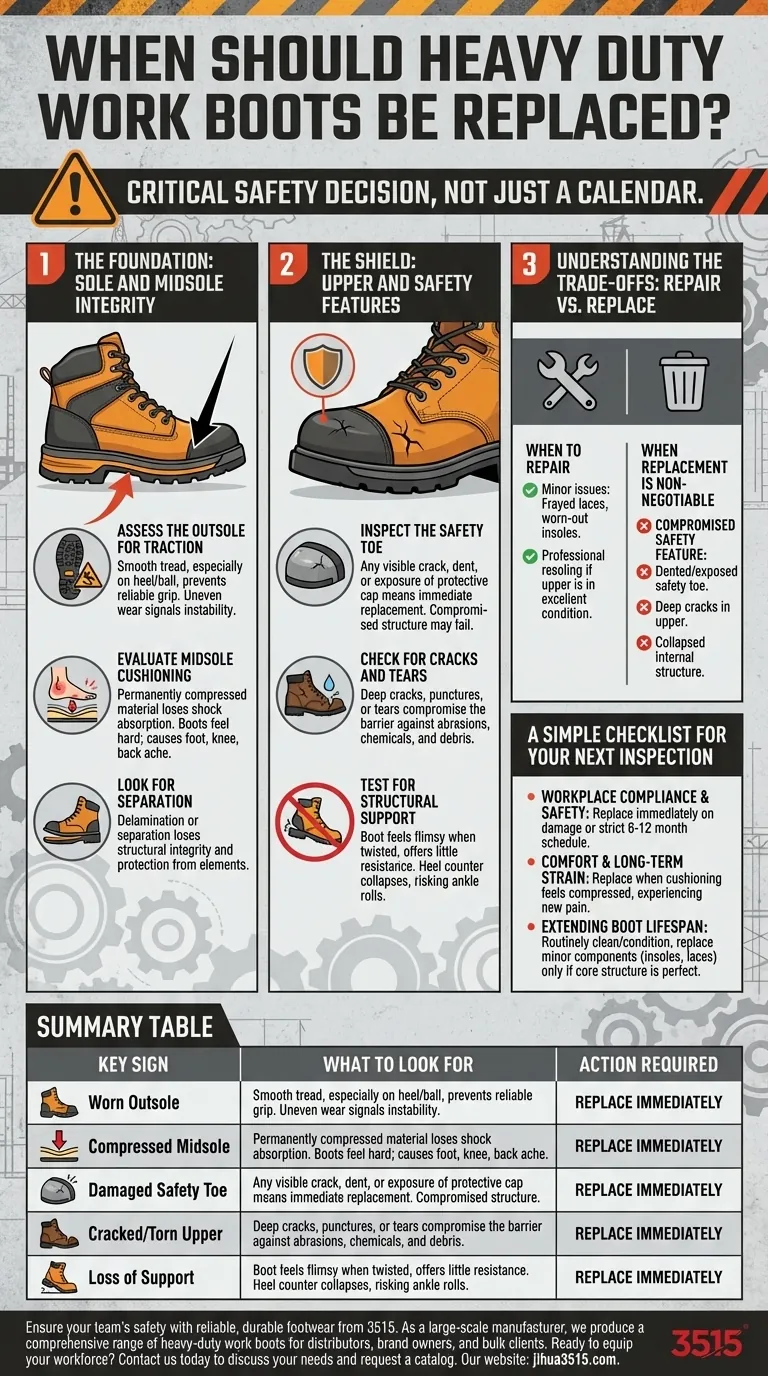

Knowing when to replace your heavy-duty work boots is a critical safety decision, not just a matter of following a calendar. You should replace them immediately when key safety features are compromised, the structural support has failed, or visible damage exposes you to risk. This includes worn-out soles that lack traction, visible damage to a safety toe, or cracks in the upper material.

While a general guideline is to replace work boots every 6 to 12 months, this is secondary to a physical inspection. The moment a boot fails to provide adequate support, traction, or protection, it becomes a direct liability to your health and safety.

The Foundation: Sole and Midsole Integrity

The sole of your boot is your primary connection to your work surface. Its failure is a clear indicator that a replacement is necessary, as it directly impacts both safety and long-term health.

Assess the Outsole for Traction

The tread on your outsole is essential for preventing slips, trips, and falls. When the patterns are worn smooth, especially in key areas like the heel or ball of the foot, the boot can no longer provide reliable grip.

Uneven wear also signals a problem, as it can alter your gait and lead to instability and joint pain.

Evaluate Midsole Cushioning

The midsole is the hidden layer that provides shock absorption. Over time, this material permanently compresses and loses its ability to cushion impact.

If your boots feel hard underfoot or your feet, knees, and back ache after a shift, the midsole has likely failed. It is no longer protecting your joints from the repetitive stress of standing and walking.

Look for Separation

Check the seams where the sole and midsole are bonded to the upper part of the boot. Any sign of delamination or separation means the boot is losing its structural integrity and can no longer protect you from water or other hazards.

The Shield: Upper and Safety Features

The upper part of the boot and its integrated safety components are your shield against impact, compression, and puncture. Damage here is non-negotiable.

Inspect the Safety Toe

This is the most critical inspection point. If you have a steel or composite toe, any visible crack, dent, or exposure of the protective cap means the boot must be replaced immediately.

A compromised safety toe has lost its structural ability to protect you from impact and may fail catastrophically when you need it most.

Check for Cracks and Tears

The leather or synthetic upper protects you from abrasions, splashes, and debris. Deep cracks, punctures, or tears compromise this barrier.

These openings allow water, chemicals, and other foreign objects to enter the boot, creating a risk of injury and infection.

Test for Structural Support

A good work boot provides firm ankle and heel support. Grab the boot by the heel and the toe and try to twist it. If it feels flimsy and offers little resistance, the internal structure has broken down.

Likewise, the heel counter should be firm. If you can easily press it flat, it will no longer stabilize your foot, increasing the risk of ankle rolls.

Understanding the Trade-offs: Repair vs. Replace

While some wear is normal, it's vital to distinguish between minor maintenance and a fundamental failure of the boot's protective capabilities.

When to Repair

Minor issues can often be addressed to extend the life of your boots. Frayed laces and worn-out insoles are simple and inexpensive to replace.

If the boot's upper is still in excellent condition, you might consider having a professional cobbler replace a worn-down outsole (resoling).

When Replacement is Non-Negotiable

Repairs cannot fix a compromised safety feature. If the safety toe is dented or exposed, the boot is finished.

Similarly, deep cracks in the upper leather or a collapsed internal structure cannot be safely repaired. At this point, the boot's core protective function is lost, and it must be replaced.

A Simple Checklist for Your Next Inspection

Use these points to make a clear, objective decision based on your primary needs.

- If your primary focus is workplace compliance and maximum safety: Replace boots immediately at the first sign of damage to any protective feature (toe, sole) or on a strict 6 to 12-month schedule in high-wear environments.

- If your primary focus is comfort and preventing long-term strain: Replace your boots when the cushioning feels compressed and you begin experiencing new foot, knee, or back pain, even if the exterior looks acceptable.

- If your primary focus is extending boot lifespan and value: Routinely clean and condition your boots and replace minor components like insoles and laces, but only if the boot's core structure and safety features remain in perfect condition.

Treating your work boots as a critical piece of personal protective equipment is the best investment you can make in your daily well-being.

Summary Table:

| Key Sign | What to Look For | Action Required |

|---|---|---|

| Worn Outsole | Tread patterns are smooth, especially on heel/ball. | Replace immediately. |

| Compressed Midsole | Boot feels hard; feet/knees/back ache after shift. | Replace immediately. |

| Damaged Safety Toe | Visible crack, dent, or exposure of the toe cap. | Replace immediately. |

| Cracked/Torn Upper | Deep cracks or punctures in leather or material. | Replace immediately. |

| Loss of Support | Boot twists easily; heel counter collapses. | Replace immediately. |

Ensure your team's safety with reliable, durable footwear from 3515.

As a large-scale manufacturer, we produce a comprehensive range of heavy-duty work boots for distributors, brand owners, and bulk clients. Our boots are engineered for maximum protection, comfort, and longevity, helping you reduce replacement costs and enhance workplace safety.

Ready to equip your workforce with superior footwear? Contact us today to discuss your needs and request a catalog.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the protective functions of industrial safety boots in sugar factory clarification stations? Thermal & Slip Experts

- What is the core function of professional safety boots within a construction Health and Safety (H&S) management system? Beyond Protection: Boost Safety & Productivity

- What primary protective functions do industrial safety shoes provide? Maximize Safety in Heavy Machinery Maintenance