The most critical signs that your wildland firefighter boots need repair or replacement are worn-out or uneven soles, dried and cracked leather, unwoven threading, and visible damage like holes or punctures. These are not minor cosmetic flaws; they are direct indicators that the boot's protective capabilities have been compromised, putting your safety on the fireline at risk.

Your boots are a critical piece of life-safety equipment. Recognizing the early signs of failure isn't just about maintenance—it's about ensuring your gear can withstand the extreme conditions you depend on it to handle.

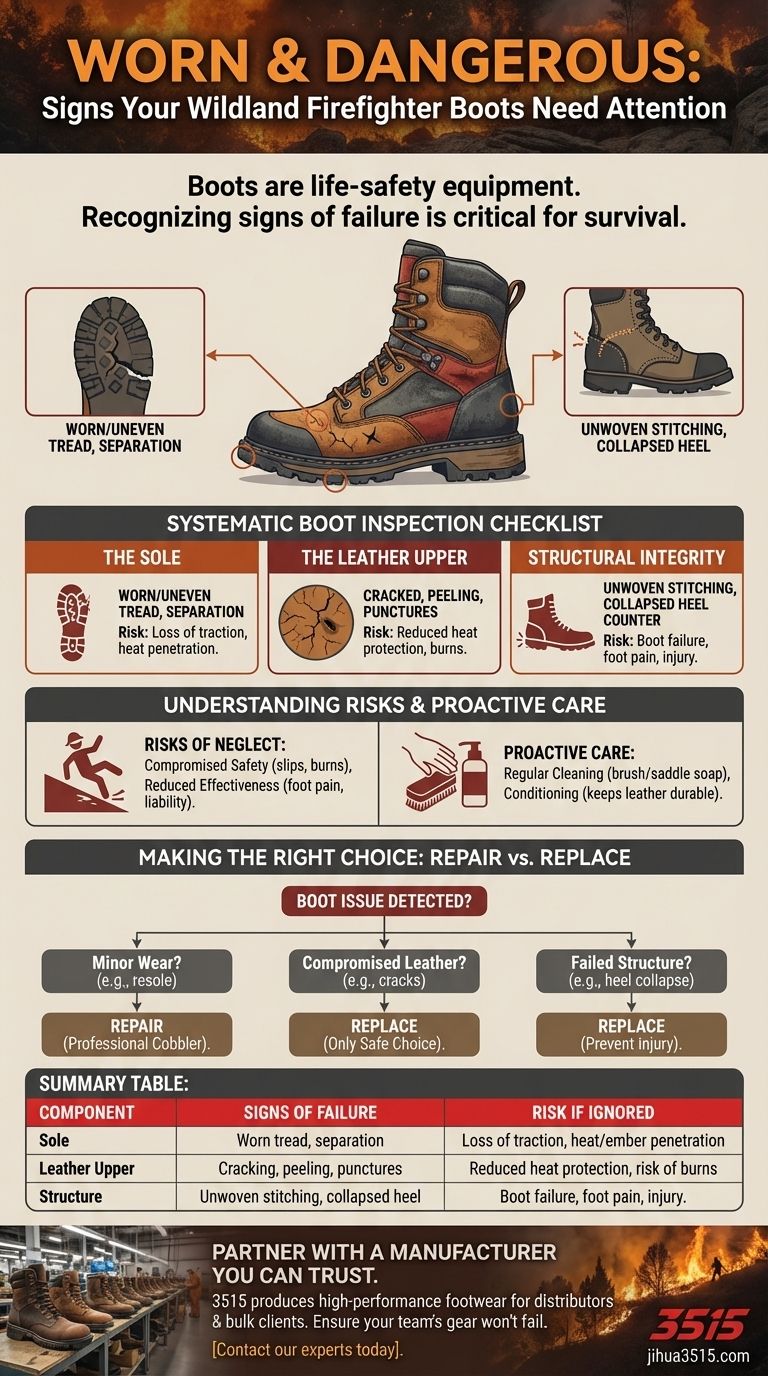

A Systematic Boot Inspection Checklist

A wildland firefighter's boot is a system of components working together. When one part fails, the entire system's integrity is jeopardized. A regular, systematic inspection is the only way to catch issues before they lead to failure in the field.

The Sole: Your Connection to the Ground

The outsole is your primary point of contact with unstable, often steep terrain. Its failure directly impacts your stability and safety.

Look for worn or uneven tread. When the lugs are gone, your slip resistance is severely diminished, increasing the risk of falls. Uneven wear can also indicate a breakdown in the boot's internal support structure.

Check for separation or ungluing, especially where the sole meets the leather upper. Even a small gap can allow embers and extreme heat to penetrate the boot.

The Leather Upper: Your Primary Shield

The leather is your main barrier against radiant heat, embers, and sharp objects. Its condition is non-negotiable.

Inspect for dried, cracked, or peeling leather. Healthy leather is supple; cracked leather has lost its structural integrity and its ability to insulate you from heat. This is a major failure point.

Search for any punctures or tears. A hole of any size is a direct pathway for embers to enter the boot, which can cause severe burns.

Structural Integrity: The Boot's Foundation

A boot's internal structure provides the support necessary to prevent injury and reduce fatigue during long shifts on your feet.

Examine all threading and stitching. If stitches are becoming unwoven or are fraying significantly, the boot is at risk of literally falling apart under stress.

Assess the insoles and heel counter. If the insoles are broken down or the reinforced heel feels soft and unsupportive, the boot can no longer properly stabilize your foot. This leads to blisters, foot pain, and potential injuries.

Understanding the Risks of Neglecting Your Boots

Ignoring the signs of boot degradation has serious consequences that extend beyond simple discomfort. It is a direct threat to your well-being and your ability to function effectively.

Compromised Safety on the Fireline

Worn-out boots are a leading cause of preventable injuries. A failed sole can lead to a slip and fall on a steep hillside, while cracked leather offers little protection from a stray ember.

Blisters, hot spots, and foot fatigue caused by collapsing internal support can be debilitating, limiting your mobility when you need it most.

Reduced Operational Effectiveness

A firefighter who is worried about their footing or distracted by foot pain is not operating at 100%. When your gear fails, you become a liability to yourself and your crew.

Timely repair and replacement ensure you can focus entirely on the task at hand without being hindered by your own equipment.

Extending Boot Life Through Proactive Care

The best way to ensure boot longevity is through consistent maintenance. This simple discipline prevents minor issues from becoming career-ending failures.

The Importance of Regular Cleaning

Due to constant exposure to dust, mud, and flame retardants, boots must be cleaned regularly. Use a horsehair brush to remove loose debris.

For deeper cleaning, use saddle soap, which cleans without stripping the leather of its essential oils.

Conditioning: The Key to Durable Leather

After cleaning, you must condition the leather. A quality conditioner keeps the leather flexible and durable, preventing the drying and cracking that ultimately destroys a boot's integrity.

This single step is the most effective way to protect your investment and ensure the leather provides a consistent thermal barrier.

Making the Right Choice: Repair vs. Replace

Knowing when to repair a boot and when to retire it is a critical judgment call. Your safety must always be the deciding factor.

- If your primary focus is addressing minor wear: A professional resole or restitching by a qualified cobbler can be a cost-effective option for high-quality, hand-stitched boots.

- If the leather upper is compromised: For any deep cracks, punctures, or significant tears in the leather, replacement is the only safe choice.

- If the internal support has failed: When the heel counter or core structure of the boot breaks down, it cannot be effectively repaired and must be replaced to prevent injury.

Ultimately, your boots are the foundation you stand on; ensure they are always worthy of your trust.

Summary Table:

| Component | Signs of Failure | Risk if Ignored |

|---|---|---|

| Sole | Worn tread, separation from upper | Loss of traction, heat/ember penetration |

| Leather Upper | Cracking, peeling, punctures | Reduced heat protection, risk of burns |

| Structure | Unwoven stitching, collapsed heel counter | Boot failure, foot pain, injury |

Don't Compromise on Safety—Partner with a Manufacturer You Can Trust

Your boots are your foundation. As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear built for the extreme demands faced by wildland firefighters, distributors, and bulk clients. Our production capabilities encompass all types of durable, safety-compliant boots designed to protect when it matters most.

We provide reliable, high-volume solutions for distributors and brand owners seeking quality and consistency. Ensure your team is equipped with gear that won't fail. Contact our experts today to discuss your specific needs and discover how we can support your mission with dependable footwear.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- How can breathability and comfort be ensured in work boots? A Guide to All-Day Foot Comfort

- How can water enter work boots despite water resistance? The 3 Main Entry Points Explained

- Why is wearing proper construction footwear important in accident-prone job sites? Protect Your Workforce

- What safety features are developed for modern Workplace Duty Boots? Essential Protection for Your Job

- What are the key features of workwear boots? A Guide to Certified Safety and Durability

- What is the best material for work boots and why? Match the Material to Your Job's Hazards

- How do cowboy boots benefit construction workers? Enhance Safety and Support on the Job Site

- What materials are commonly used in modern work boots for comfort? A Guide to All-Day Support