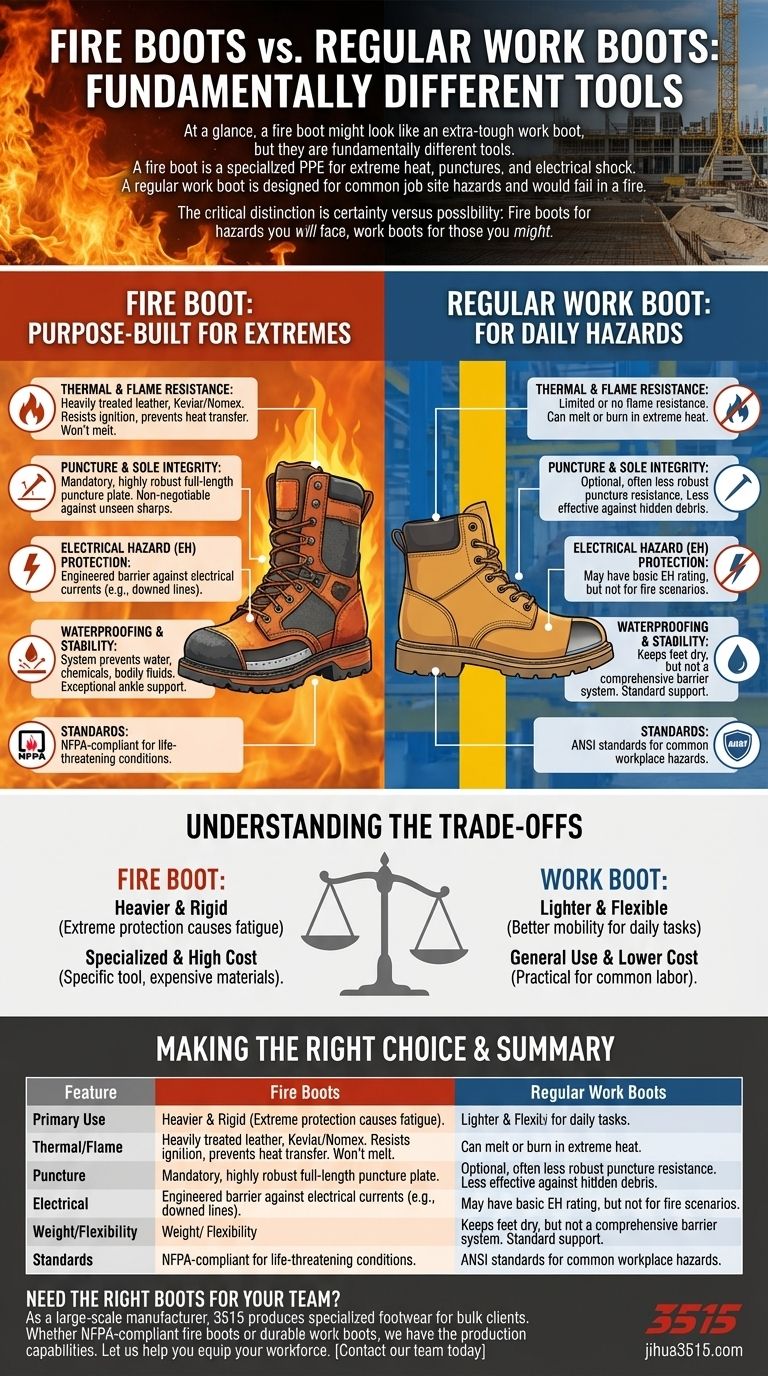

At a glance, a fire boot might look like an extra-tough work boot, but they are fundamentally different tools. A fire boot is a highly specialized piece of personal protective equipment (PPE) engineered to withstand extreme heat, resist punctures from unseen debris, and insulate against electrical shock. A regular work boot, even a heavy-duty one, is not designed for these life-threatening conditions and would fail catastrophically in a fire.

The critical distinction is one of certainty versus possibility. A standard work boot protects you from hazards you might encounter on a job site. A fire boot is built to protect you from the extreme hazards you will certainly face in an emergency.

The Core Design Philosophy: Purpose-Built for Extremes

Understanding the difference between these boots starts with their core purpose. Each is designed to solve a completely different set of problems in radically different environments.

The Role of a Regular Work Boot

A high-quality work boot is designed for the known hazards of a construction site, workshop, or industrial environment.

Its primary functions are to protect against impact from dropped objects, compression, and occasional punctures from common job site materials.

The Unforgiving World of Firefighting

A fire boot is built for a multi-hazard environment where conditions are unpredictable and extreme.

Firefighters face intense radiant heat, direct flame contact, and the risk of stepping on nails, glass, or rebar hidden in debris. They must also navigate water-soaked, unstable surfaces with the constant threat of live electricity.

A Feature-by-Feature Breakdown

While both boots may share features like a safety toe, the materials and construction standards are worlds apart.

Thermal & Flame Resistance

This is the most significant difference. Fire boots are constructed from heavily treated leather and advanced, fire-resistant fabrics like Kevlar or Nomex.

These materials are designed to resist ignition, prevent heat transfer to the foot, and maintain their structural integrity even after being exposed to extreme temperatures. A regular work boot would simply melt or burn.

Puncture & Sole Integrity

Fire boots contain a mandatory, highly robust puncture-resistant plate that runs the length of the sole. This is non-negotiable protection against unseen sharps.

While some work boots offer puncture resistance, the standards for fire boots are more rigorous to account for the certainty of hazardous debris.

Electrical Hazard (EH) Protection

Fire boots are specifically engineered and tested to provide a barrier against electrical currents.

This is a critical safety feature for structure fires where downed power lines or faulty wiring present a deadly, invisible threat. This level of EH protection is a specialized feature not present in most work boots.

Waterproofing and Stability

Beyond just keeping feet dry, the waterproofing in a fire boot is part of a system. It prevents water, chemicals, and bodily fluids from reaching the skin.

They also provide exceptional ankle support to prevent injury when moving quickly over unstable, compromised flooring and terrain.

Understanding the Trade-offs: Not a Daily Driver

Given their superior protective qualities, it might seem logical to use a fire boot for all tough jobs. However, this would be impractical and inefficient.

Weight and Rigidity

The materials that provide extreme protection make fire boots significantly heavier and more rigid than standard work boots.

This weight and lack of flexibility would cause fatigue and hinder mobility in a typical work environment that requires agility and constant movement.

Cost and Specialization

Fire boots are specialized equipment made from expensive materials, putting them at a much higher price point than even premium work boots.

They are a specific tool for a specific, life-threatening job. Using one for general labor is overkill and ill-suited for the task.

Making the Right Choice for Your Goal

Selecting the correct footwear is about accurately assessing your environment and its specific risks.

- If your primary focus is firefighting or hazardous material response: There is no substitute. Only a certified NFPA-compliant fire boot will provide the necessary, life-saving protection.

- If your primary focus is construction, manufacturing, or a skilled trade: A high-quality work boot with the correct safety toe (steel or composite) and any other required features (like puncture resistance) is the proper tool for the job.

- If your primary focus is agility and support for active duty: A tactical boot offers a better balance of lightweight performance, flexibility, and durability than a heavy work boot.

Choosing the right boot isn't about finding the "toughest" option; it's about precisely matching your protective equipment to the specific risks you will face.

Summary Table:

| Feature | Fire Boots | Regular Work Boots |

|---|---|---|

| Primary Use | Firefighting, Hazmat Response | Construction, Industrial Work |

| Thermal/Flame Resistance | Extreme heat resistance, fire-resistant materials | Limited or no flame resistance |

| Puncture Protection | Mandatory, full-length puncture plate | Optional, often less robust |

| Electrical Hazard (EH) Protection | Specifically engineered for electrical shock | May have basic EH rating, not for fire scenarios |

| Weight & Flexibility | Heavy and rigid for extreme protection | Lighter and more flexible for daily tasks |

| Standards | NFPA-compliant for life-threatening conditions | ANSI standards for common workplace hazards |

Need the Right Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of specialized footwear for distributors, brand owners, and bulk clients. Whether you need NFPA-compliant fire boots for emergency responders or durable work boots for industrial crews, we have the production capabilities and expertise to meet your exact requirements.

Let us help you equip your workforce with the right protection. Contact our team today to discuss your project and get a custom quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What should you look for in puncture-resistant work boots to ensure compliance? Verify the ASTM F2413 'PR' Label

- Why is proper fit important in work boots? Ensure Safety, Comfort & Long-Term Health

- What specific design features must industrial boots have to withstand the thermal and chemical risks in a sugar refinery? Ensure Ultimate Worker Safety & Durability

- What additional features do wildland boots have? Unmatched Protection for Extreme Conditions

- What are the advantages of soft toe work boots? Boost Comfort & Mobility for Long Shifts

- What was the traditional use of moc toe boots? Built for American Workers & Hunters

- Why does boot height matter for winter work? A Guide to Safety, Warmth, and Performance

- Why is toe protection important in farming and gardening boots? Prevent Crushing Injuries from Heavy Tools and Livestock