Keeping your boot outsoles completely dry is a critical safety protocol. This is because moisture fundamentally compromises their electrical-resistant properties, turning your primary protection against electrical shock into a potential conductor for dangerous currents.

The core principle is simple: while dry rubber and specialized sole compounds are excellent insulators, water is a conductor. A wet outsole can create a direct path for electricity to travel through your body to the ground, completely nullifying the boot's designed safety features.

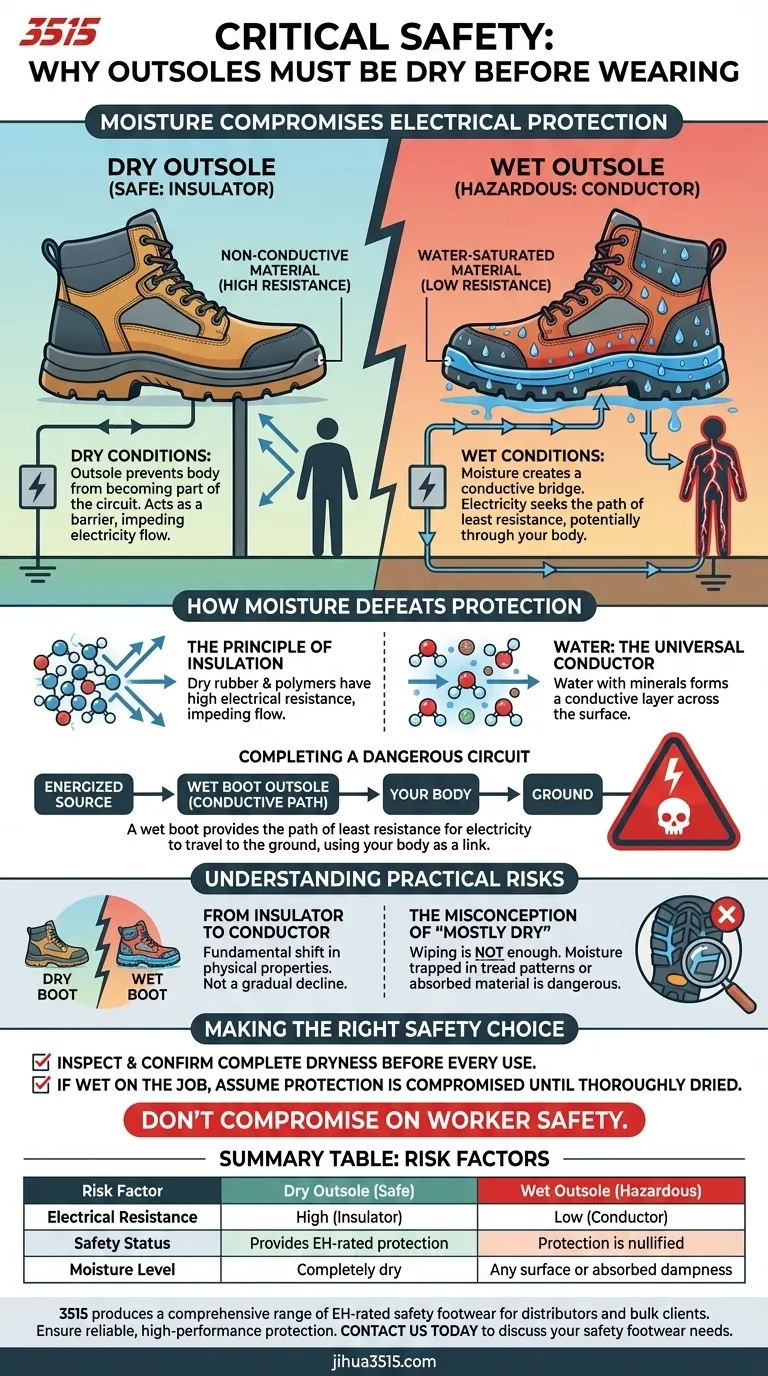

How Moisture Defeats Electrical Protection

To understand the risk, it's essential to grasp how Electrical Hazard (EH) rated footwear is designed to work and how easily moisture undermines that design.

The Principle of Insulation

Properly rated safety boots use outsoles made from non-conductive materials like rubber and specific polymers. These materials have very high electrical resistance, meaning they act as a barrier that impedes the flow of electricity.

Under dry conditions, if you accidentally step on a live electrical source, the outsole is designed to prevent your body from becoming part of the circuit, thereby protecting you from shock.

Water: The Universal Conductor

Water, especially water found in work environments, contains minerals and impurities. These dissolved particles allow it to conduct electricity effectively.

When the outsole of your boot becomes wet, this layer of moisture forms a conductive bridge across the entire surface that is meant to be insulating.

Completing a Dangerous Circuit

The real danger occurs when this moisture creates a pathway for current. Electricity will always seek the path of least resistance to the ground.

A wet boot outsole provides that path. It allows electricity to flow from the energized source, through the layer of water, and into the ground, often using your body as the final link in that deadly circuit.

Understanding the Practical Risks

The change from a dry, safe boot to a wet, hazardous one is not always visually dramatic. This "hidden" nature of the risk is what makes it so critical to address.

From Insulator to Conductor

A dry EH-rated boot is a reliable insulator. The moment it becomes sufficiently wet, it effectively becomes a conductor. This is not a gradual decline in performance; it is a fundamental shift in its physical properties.

The Misconception of "Mostly Dry"

Simply wiping the boot's surface is often not enough. Moisture can be absorbed into the outsole material or trapped in the tread patterns.

For this reason, boots must be completely and thoroughly dry before you can trust their electrical-resistant capabilities. Any lingering dampness presents an unacceptable risk.

Making the Right Safety Choice

Your personal safety depends on treating your protective equipment with the diligence it requires. This principle is non-negotiable in environments with electrical hazards.

- If your primary focus is personal safety in an EH environment: Your boots must be inspected and confirmed to be completely dry before every single use.

- If your boots become wet while on the job: You must assume their electrical protection is compromised until they can be removed and thoroughly dried out again.

Ultimately, a simple, mandatory check of your equipment is your most reliable defense against a potent and invisible hazard.

Summary Table:

| Risk Factor | Dry Outsole (Safe) | Wet Outsole (Hazardous) |

|---|---|---|

| Electrical Resistance | High (Acts as an insulator) | Low (Acts as a conductor) |

| Safety Status | Provides EH-rated protection | Protection is nullified |

| Moisture Level | Completely dry | Any surface or absorbed dampness |

Don't Compromise on Worker Safety. As a large-scale manufacturer, 3515 produces a comprehensive range of EH-rated and other safety footwear for distributors, brand owners, and bulk clients. Our expertise ensures your teams have reliable, high-performance protection. Contact us today to discuss your safety footwear needs and enhance your workplace safety protocols.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What are the properties of EVA outsoles in safety shoes? Discover the Ultimate Comfort for Long Shifts

- How do Intelligent Tags in Safety Shoes ensure compliance? Revolutionize Workplace Safety with Real-Time PPE Verification

- How does the systematic configuration of PPE contribute to footwear production stability? Secure Your Line Efficiency

- How can the mechanical design of professional footwear alleviate falls? Engineering Stability and Balance Support

- Why are professional safety shoes required during heavy-duty girder erection? Essential Protection for Infrastructure

- How is human joint motion monitoring technology applied to the research and development of safety shoes? Design Insights

- What industries require composite-toe boots? Choose the Right Protection for Your Job Hazards

- Why is it important to balance cost and durability when purchasing safety boots? Maximize Long-Term Value