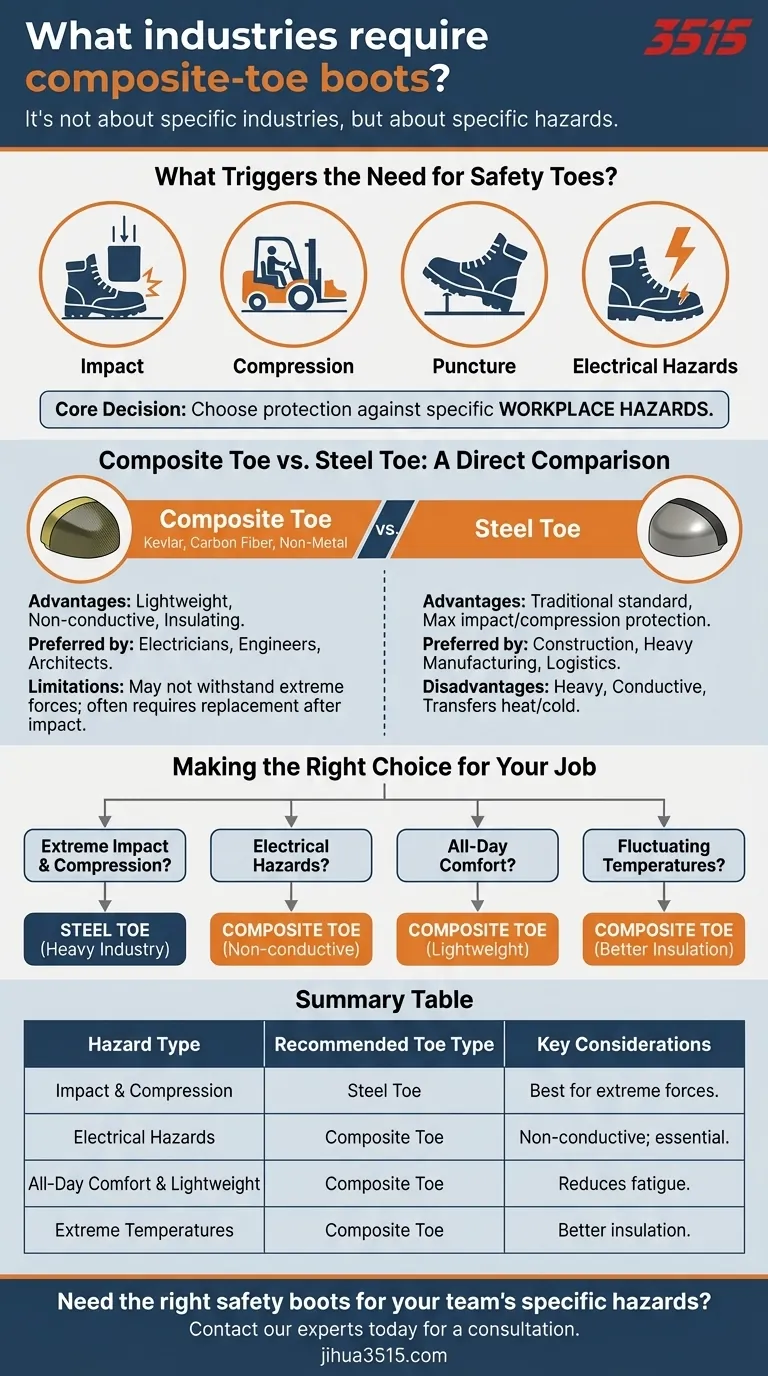

It's not about specific industries, but about specific hazards. While many industries like construction, manufacturing, and logistics have roles that require safety footwear, the choice between composite-toe and other safety boots depends entirely on the specific risks present in the work environment, such as impact, compression, and electrical hazards.

The core decision is not about choosing a boot for an industry but about choosing protection against a specific workplace hazard. Composite-toe boots are a modern solution for jobs requiring impact protection without the conductivity and weight of steel.

The Role of Hazard Assessment

The foundation of any safety footwear requirement is a thorough hazard assessment. The Occupational Safety and Health Administration (OSHA) mandates that employers identify and protect employees from potential foot injuries.

What Triggers the Need for Safety Toes?

The primary driver for any safety-toe boot, whether composite or steel, is the risk of foot injury from falling or rolling objects. This is common in environments where heavy materials or equipment are handled.

Key Hazards to Consider

- Impact: The risk of something heavy dropping directly onto the foot.

- Compression: The danger of the foot being crushed under a heavy rolling object, like a forklift or pallet jack.

- Puncture: The risk of sharp objects like nails or scrap metal piercing the sole of the boot.

- Electrical Hazards: The presence of live circuits or static electricity that could cause shock or sparks.

Composite Toe vs. Steel Toe: A Direct Comparison

Understanding the functional differences between composite and steel toes is crucial for selecting the right protection.

The Case for Composite Toes

Composite-toe caps are made from non-metal materials like Kevlar, carbon fiber, or plastic. This construction gives them distinct advantages in certain environments.

They are often preferred by electricians, engineers, architects, and project managers who need protection but may also work in environments with electrical risks or metal detectors.

The Case for Steel Toes

Steel-toe boots are the traditional standard for heavy-duty protection. They are commonly used in construction, heavy manufacturing, and logistics where the risk of severe impact and compression is highest.

Understanding the Trade-offs

Neither boot type is universally superior; the choice is always a matter of balancing protection, comfort, and environmental factors.

Composite Toe Limitations

While strong, composite toes may not withstand the same extreme impact and compression forces as steel. After a significant impact, the protective structure can be compromised, often requiring the boots to be replaced.

Steel Toe Disadvantages

Steel's primary drawbacks are its weight and its conductivity. Steel toes transfer heat and cold more readily, making them less comfortable in extreme temperatures. They are also conductive, making them unsuitable for some jobs with electrical hazards.

Making the Right Choice for Your Job

Your final decision should be based on a clear-eyed assessment of your daily tasks and the specific dangers you face.

- If your primary focus is protection against extreme impact and compression: A steel-toe boot is the most reliable choice for heavy industrial or construction environments.

- If your primary focus is protection with electrical hazard resistance: A composite-toe boot is the definitive option to avoid electrical conductivity.

- If your primary focus is all-day comfort and reduced fatigue: A lighter composite-toe boot is often preferable for roles requiring long hours of walking without constant heavy-object risk.

- If you work in environments with fluctuating temperatures: Composite materials provide better insulation against both heat and cold.

Ultimately, the best safety boot is the one that directly counters the specific hazards of your workplace.

Summary Table:

| Hazard Type | Recommended Toe Type | Key Considerations |

|---|---|---|

| Impact & Compression | Steel Toe | Best for extreme forces in heavy industry/construction. |

| Electrical Hazards | Composite Toe | Non-conductive; essential for electricians and live circuits. |

| All-Day Comfort & Lightweight | Composite Toe | Reduces fatigue for roles with long hours of walking. |

| Extreme Temperatures | Composite Toe | Provides better insulation against heat and cold. |

Need the right safety boots for your team's specific hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Whether your priority is maximum steel-toe protection or the lightweight, non-conductive advantages of composite toes, we have the production capabilities to meet your needs.

Contact our experts today for a consultation on the perfect safety footwear solution for your workplace.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What are the benefits of heavy duty work boots? Invest in Superior Safety & Durability

- What is the core protective function of steel-toe safety shoes in preventing lower limb injuries caused by chainsaws?

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection