At its core, an EVA outsole in a safety shoe is defined by its exceptional lightness, flexibility, and high-impact shock absorption. This plastic material, ethylene-vinyl acetate, is engineered to significantly reduce the weight of the footwear, directly combating user fatigue over long work periods.

The central trade-off with EVA is choosing between unparalleled comfort and certain environmental limitations. While its lightweight and shock-absorbing nature is a major benefit, its lack of breathability and lower resistance compared to materials like rubber must be considered for your specific work conditions.

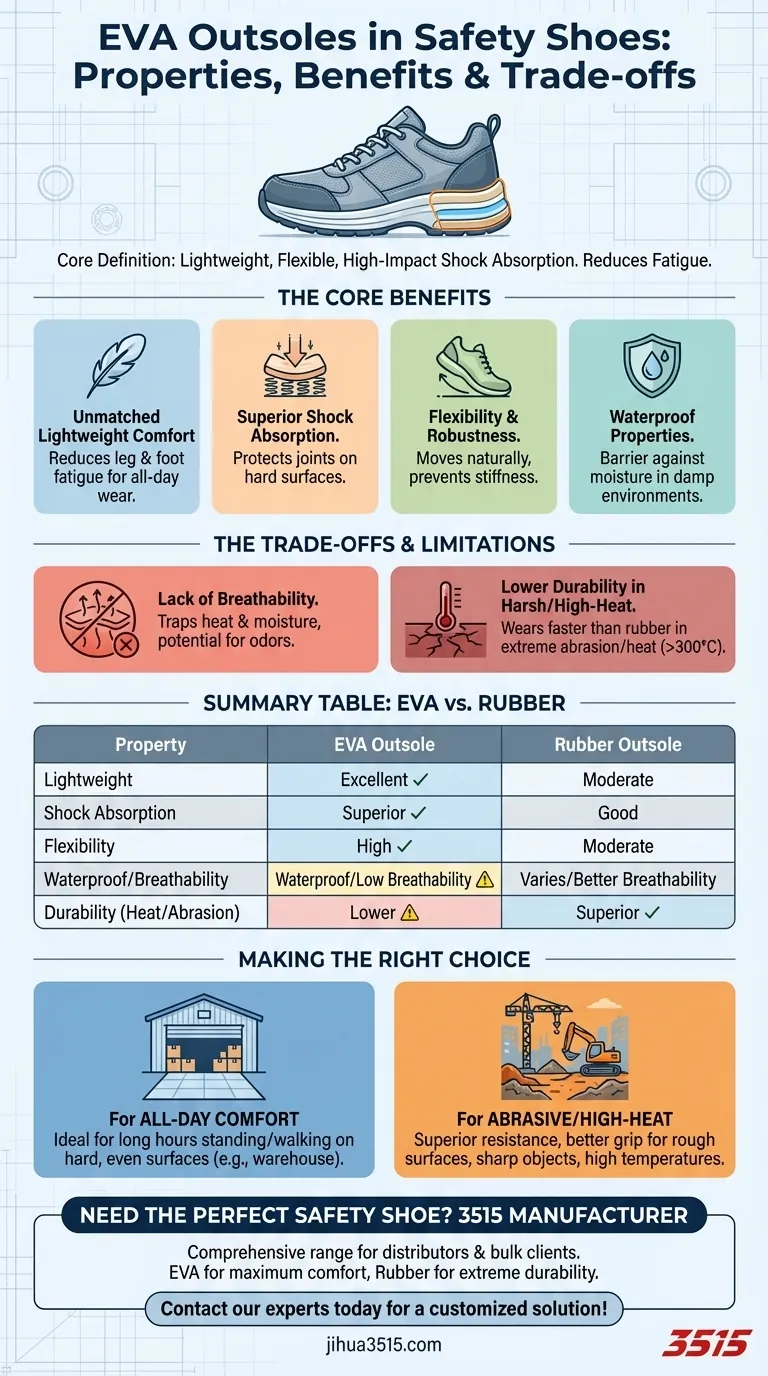

The Core Benefits of EVA in Safety Footwear

EVA is not just another plastic; its unique molecular structure provides several distinct advantages when used as an outsole material for safety shoes. These properties are centered around enhancing user comfort and reducing physical strain.

Unmatched Lightweight Comfort

EVA is an extremely lightweight material. This directly translates to a lighter safety shoe, which is a critical factor in reducing leg and foot fatigue for workers who are on their feet all day.

Superior Shock Absorption

The material is soft and supple, allowing it to absorb high impacts effectively. This cushioning protects the wearer's joints from the constant stress of walking or standing on hard surfaces.

Flexibility and Robustness

Despite its softness, EVA is a hard-wearing and robust material. Its inherent flexibility allows the shoe to bend and move naturally with the foot, preventing stiffness and enhancing overall comfort.

Waterproof Properties

EVA is a waterproof material, which provides a barrier against moisture from the outside. This can be a significant advantage in damp working environments.

Understanding the Trade-offs and Limitations

No single material is perfect for every application. The very properties that make EVA an excellent choice for comfort also introduce specific limitations that are crucial to understand.

Lack of Breathability

The primary drawback of EVA is its waterproof, non-porous nature. It does not allow for air exchange between the inside and outside of the shoe.

This can trap heat and moisture, leading to increased humidity and the potential for unpleasant odours, especially during extended wear or in warm conditions.

Durability in Harsh Environments

While robust, EVA's primary strengths are not in extreme abrasion or heat resistance. Materials like rubber are specifically noted for their ability to withstand high heat (up to 300°C) and superior abrasion resistance.

For environments with rough surfaces, sharp objects, or high temperatures, an EVA outsole may wear down more quickly than a specialized rubber counterpart.

Making the Right Choice for Your Needs

Selecting the correct outsole material is about matching its properties to your daily work environment and physical demands.

- If your primary focus is all-day comfort and reducing fatigue: An EVA outsole is an excellent choice for long hours of standing or walking on hard, even surfaces like concrete or warehouse floors.

- If your primary focus is durability in abrasive or high-heat conditions: A rubber outsole is the more suitable option, offering superior resistance to wear, heat, and providing better adhesive grip.

Ultimately, choosing the right safety shoe means understanding that the outsole material is a key component in balancing your need for comfort with the demands of your job.

Summary Table:

| Property | Advantage | Consideration |

|---|---|---|

| Lightweight | Reduces foot and leg fatigue | - |

| Shock Absorption | Protects joints on hard surfaces | - |

| Flexibility | Moves naturally with the foot | - |

| Waterproof | Barrier against external moisture | Leads to lack of breathability |

| Durability | Robust for general use | Lower heat/abrasion resistance than rubber |

Need the perfect safety shoe for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including models with EVA outsoles for maximum comfort or specialized rubber compounds for extreme durability.

Let us help you find the ideal balance of comfort and protection. Contact our experts today for a customized solution!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today