At its core, high-grade rubber is used in slip-resistant shoe soles because its inherent material properties provide superior traction. It excels at gripping surfaces, particularly those contaminated with grease or water, by creating a higher coefficient of friction than most other materials.

The choice of high-grade rubber is the first step, but true slip resistance is a system. It emerges from the combination of the right material, an intelligent outsole design, and its specific application to counter workplace hazards.

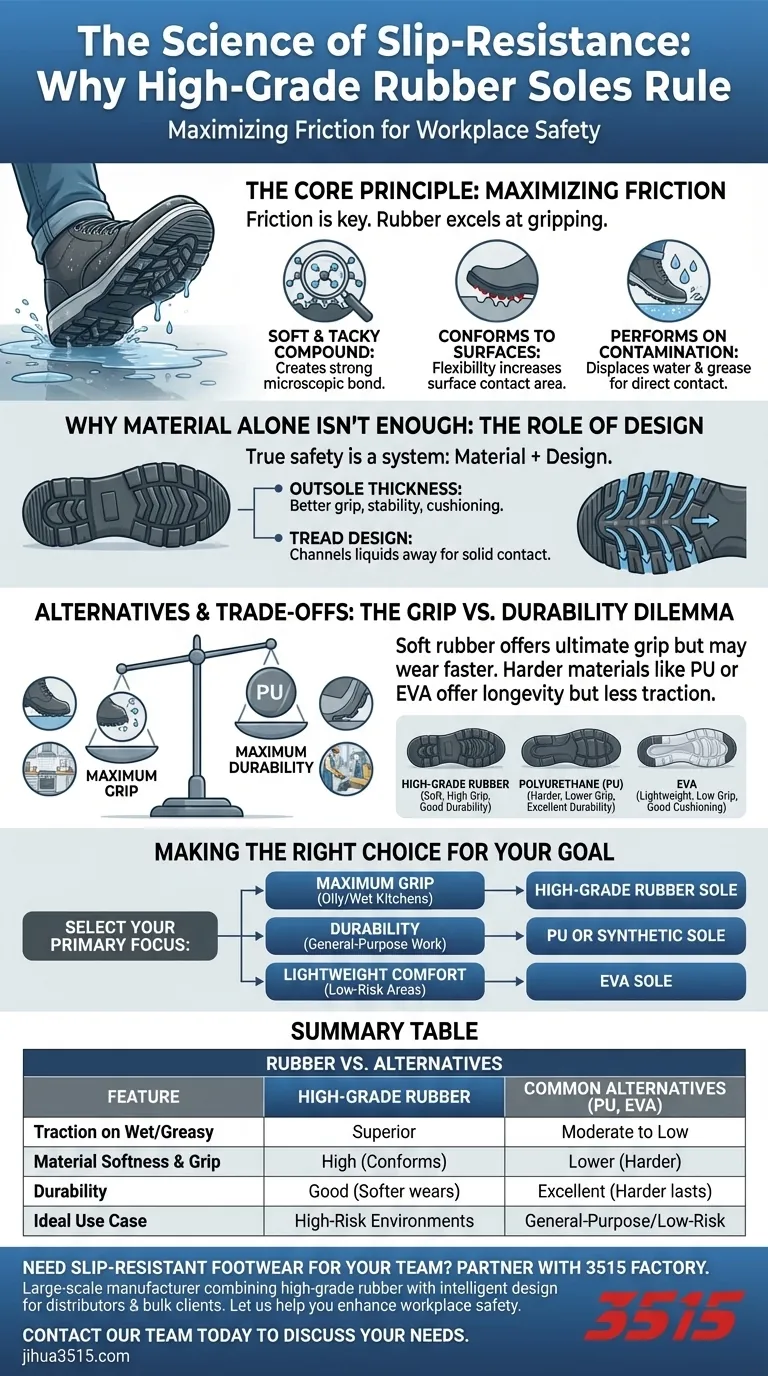

The Core Principle: Maximizing Friction

A slip occurs when there is not enough friction between your shoe and the walking surface. The entire purpose of a slip-resistant sole is to maximize this friction under a variety of conditions.

How Rubber Creates Grip

High-grade rubber compounds are formulated to be relatively soft and tacky. This allows the material to establish a stronger bond at a microscopic level with the floor, creating the resistance needed to prevent sliding.

Conforming to the Surface

The flexibility of rubber enables it to conform to the tiny, invisible imperfections present on almost any floor. This increases the total surface area in contact with the ground, which directly translates to a more secure grip.

Performance on Contaminated Surfaces

This is where high-grade rubber truly excels. Its composition is effective at displacing thin layers of liquids like water and grease, allowing the sole to make direct contact with the solid surface underneath and maintain traction where other materials would hydroplane.

Why Material Alone Isn't Enough

Simply using rubber is not a guarantee of safety. The physical design of the outsole plays an equally critical role in how that material performs.

The Role of Outsole Thickness

Thicker outsoles often contribute to better grip and stability. The added material provides more cushioning and a more substantial platform, which can improve the sole's ability to maintain even contact with the ground on slippery surfaces.

The Importance of Tread Design

An effective tread pattern is essential for channeling liquids away from the bottom of the shoe. Well-designed channels and grooves move water, oil, and other contaminants out from under the sole, ensuring the rubber makes solid contact with the floor.

Understanding the Alternatives and Trade-offs

While rubber is a top performer for grip, it is not the only option. Understanding the alternatives highlights the specific reasons rubber is often chosen for high-risk environments.

Common Alternative Materials

Other materials used for shoe soles include Polyurethane (PU), EVA (ethylene vinyl acetate), and various synthetic compounds. Each offers a different balance of properties.

The Durability vs. Grip Dilemma

There is often a direct trade-off between maximum grip and long-term durability. The softest, grippiest rubber compounds can wear down more quickly than harder materials like polyurethane. The choice of material becomes a balance between the need for ultimate safety and the desire for a longer-lasting shoe.

Making the Right Choice for Your Goal

The ideal sole material depends entirely on the specific hazards of your environment.

- If your primary focus is maximum grip in oily or wet kitchens: A sole made from a high-grade, soft rubber compound is the definitive choice for safety.

- If your primary focus is durability for general-purpose work: A polyurethane or a harder synthetic compound may provide a better balance of longevity and adequate slip resistance.

- If your primary focus is lightweight comfort for low-risk areas: An EVA sole offers excellent cushioning but typically sacrifices the high-level grip needed for hazardous surfaces.

Ultimately, choosing the right footwear requires you to match the sole's material and design to the specific challenges you will face.

Summary Table:

| Feature | High-Grade Rubber | Common Alternatives (e.g., PU, EVA) |

|---|---|---|

| Traction on Wet/Greasy Surfaces | Superior | Moderate to Low |

| Material Softness & Grip | High (Conforms to surfaces) | Lower (Harder compounds) |

| Durability | Good (Softer compounds wear faster) | Excellent (Harder materials last longer) |

| Ideal Use Case | High-risk environments (e.g., kitchens) | General-purpose or low-risk areas |

Need Slip-Resistant Footwear for Your Team? Partner with 3515 Factory.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We expertly combine high-grade rubber compounds with intelligent tread designs to create soles that deliver maximum traction and durability for your specific workplace hazards.

Let us help you enhance workplace safety. Contact our team today to discuss your custom footwear needs and receive a quote.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What are the differences between leather and rubber outsoles? Choose the Right Foundation for Your Footwear

- How does a high-performance GPU contribute to the real-time efficiency of an automated shoe sole spraying line?

- How do you clean white rubber shoes? Restore Them to Like-New Condition

- What roles do TPU and Rubber play in footwear sole systems? Engineering the Perfect Balance of Grip and Cushioning

- What is the importance of slip-resistant outsoles in preventing Lower Back Pain? Stabilize Your Spine with Every Step

- What are the main applications of vulcanized rubber? Unlock Durability for Tires, Footwear & More

- What is the primary function of high-performance rubber outsoles? Master Traction in Extreme Weather

- What is vulcanized rubber and why is it used in products? The Key to Durable, Flexible Footwear