At its core, vulcanized rubber is the material of choice for applications demanding exceptional durability and elasticity. Its most prominent uses are in vehicle tires, which consume the majority of global production, and in the soles of footwear, particularly sneakers, where its toughness and flexibility are essential.

The key takeaway is not just what vulcanized rubber is used for, but why. The vulcanization process fundamentally transforms soft, sticky natural rubber into a strong, resilient, and stable engineering material, making it indispensable for any product that must withstand constant stress, friction, and environmental exposure.

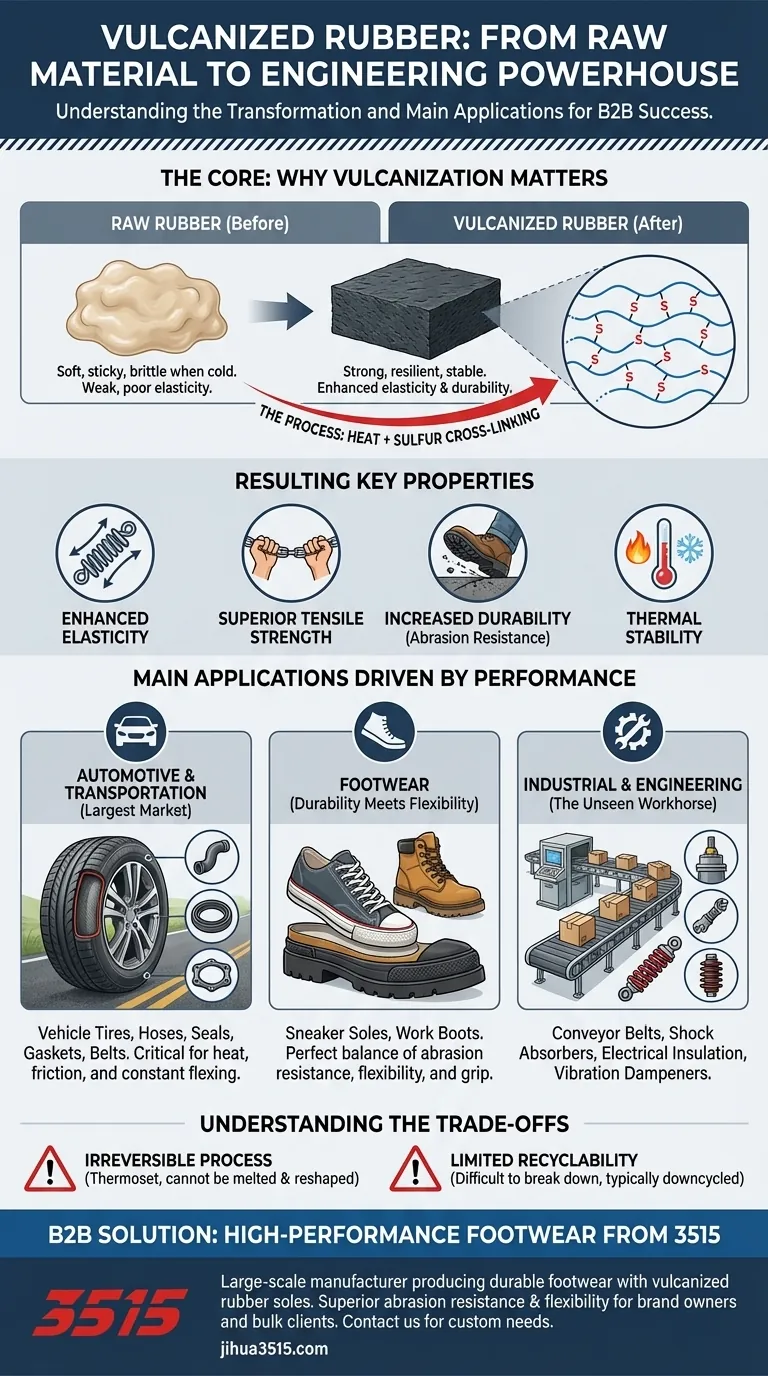

What is Vulcanization and Why Does It Matter?

To understand its applications, you must first understand the transformation. Vulcanization solves the inherent weaknesses of raw, natural rubber.

The Problem with Natural Rubber

Raw rubber is of limited practical use. It becomes soft and sticky when warm, brittle when cold, and has poor tensile strength and elasticity. It does not reliably return to its original shape after being stretched.

The Chemical Transformation

Vulcanization, discovered by Charles Goodyear, is a chemical process that involves heating rubber with sulfur. This creates strong cross-links between the long polymer chains of the rubber molecules.

Think of raw rubber as a plate of cooked spaghetti—the strands can slide past each other easily. Vulcanization is like adding a binding agent that connects all those strands into a single, cohesive, springy net.

The Resulting Properties

This cross-linking process dramatically improves the material's properties, giving it:

- Enhanced Elasticity: The ability to stretch significantly and return to its original shape.

- Superior Tensile Strength: A much greater resistance to being pulled apart.

- Increased Durability: High resistance to abrasion, tearing, and general wear.

- Thermal Stability: The ability to maintain its properties over a wider range of temperatures.

Key Applications Driven by Core Properties

The superior properties of vulcanized rubber make it the definitive choice for thousands of products across multiple industries.

Automotive and Transportation: The Ultimate Test

This is the largest market for vulcanized rubber. Its ability to withstand heat, friction, and constant flexing is critical.

Applications include vehicle tires, hoses, seals, gaskets, and belts. In each case, the material must perform reliably under extreme mechanical and thermal stress without degrading.

Footwear: Durability Meets Flexibility

Vulcanized rubber is the standard for high-quality shoe soles, especially for sneakers and work boots.

The material provides the perfect combination of abrasion resistance to handle contact with pavement and flexibility to allow for natural foot movement, all while offering excellent grip.

Industrial and Engineering: The Unseen Workhorse

In industrial settings, vulcanized rubber is essential for components that must absorb energy and resist harsh conditions.

It is used for conveyor belts, shock absorbers, electrical insulation, and vibration dampeners. Its ability to form a perfect seal also makes it crucial for industrial tubing and gaskets.

Understanding the Trade-offs

While incredibly useful, vulcanized rubber is not without its limitations. Understanding these is key to proper material selection.

Irreversible Curing Process

Vulcanization is a thermoset process, meaning it is irreversible. Once the rubber is cured, it cannot be melted down and reshaped like a thermoplastic. This makes manufacturing more complex.

Limited Recyclability

The same chemical cross-links that give the material its strength make it very difficult to recycle. While tires can be shredded and repurposed (a process called "downcycling"), they cannot be easily broken down to their base polymers.

Making the Right Choice for Your Goal

Selecting vulcanized rubber depends entirely on the performance requirements of your application.

- If your primary focus is extreme durability and abrasion resistance: Vulcanized rubber is the ideal choice for demanding applications like tires, industrial belts, and shoe soles.

- If your primary focus is creating a reliable, flexible seal: Its elasticity and resistance to compression make it perfect for gaskets, O-rings, and automotive hoses.

- If your primary focus is high-volume, low-cost manufacturing and recyclability: You should consider a thermoplastic elastomer (TPE) as an alternative, though it may not offer the same level of performance.

Ultimately, vulcanization is the process that unlocks rubber's true potential, transforming it from a raw substance into a cornerstone of modern engineering.

Summary Table:

| Application | Key Properties Utilized | Common Examples |

|---|---|---|

| Automotive & Transportation | Heat resistance, durability, elasticity | Tires, hoses, seals, gaskets |

| Footwear | Abrasion resistance, flexibility, grip | Sneaker soles, work boots |

| Industrial & Engineering | Shock absorption, sealing, vibration dampening | Conveyor belts, shock absorbers, insulation |

Need high-performance vulcanized rubber footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our vulcanized rubber soles offer superior abrasion resistance and flexibility, perfect for demanding applications.

Contact us today to discuss your custom footwear needs and leverage our full production capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- What is the physical mechanism behind incorporating small rubber particles on compression socks for balance function?

- What is the purpose of Teflon coating on outsole molds? Boost Production & Protect Molds

- What are the most popular materials used for making shoe soles? Choose the Right Material for Durability & Comfort

- What are the breathability benefits of natural rubber in footwear? Achieve All-Day Foot Comfort

- What makes rubber soles effective for slip resistance? Discover the Science of Traction

- What are the main differences between leather and rubber shoe soles? Choose the Right Sole for Your Needs

- What are the functional benefits of natural rubber soles beyond sustainability? Unlock Superior Durability & Traction

- Why might someone prefer rubber soles over leather soles? Unlock Durability & All-Weather Performance