In short, vulcanized rubber is natural rubber that has been chemically hardened and strengthened. This is achieved by heating raw rubber with sulfur, a process that fundamentally alters its molecular structure to make it significantly more durable, flexible, waterproof, and resistant to changes in temperature.

The core purpose of vulcanization is to solve natural rubber's fatal flaw: its instability. By creating chemical "bridges" within the material, the process transforms a weak, sticky substance into a resilient, high-performance material suitable for everything from footwear to car tires.

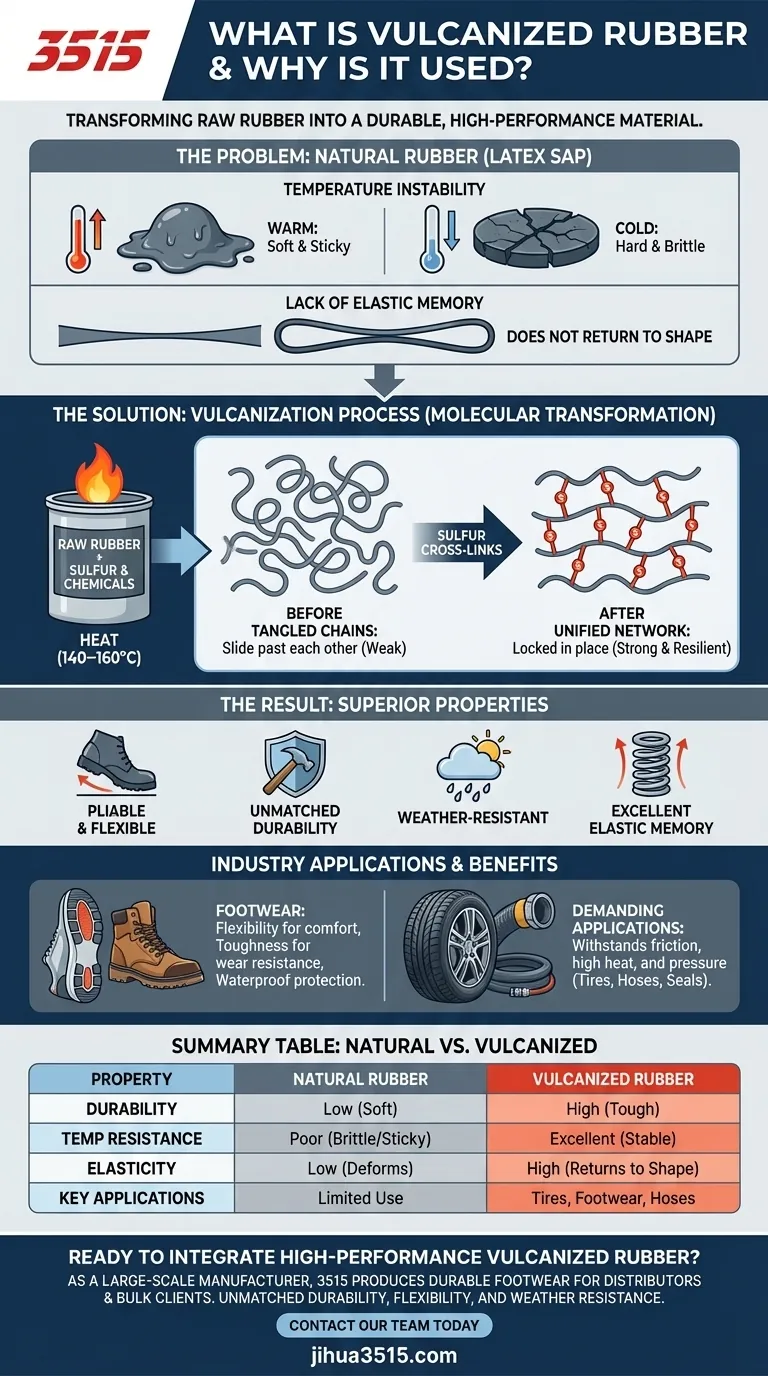

The Problem with Natural Rubber

Before vulcanization, natural rubber (latex sap) has limited practical use. Its properties change dramatically and unpredictably with its environment.

Temperature Instability

In its raw state, rubber becomes soft and sticky when it gets warm. Conversely, when it gets cold, it turns hard and brittle, easily cracking under stress.

Lack of Elastic Memory

While natural rubber can stretch, it doesn't effectively return to its original shape after being deformed. This lack of resilience makes it unsuitable for applications requiring consistent performance.

How Vulcanization Works: A Molecular Transformation

The vulcanization process, discovered by Charles Goodyear in 1839, permanently solves these issues by reorganizing the rubber's internal structure.

The Role of Sulfur and Heat

The process involves mixing raw rubber with sulfur and other chemical agents. This mixture is then heated to a high temperature, typically between 140–160°C.

Creating a Cross-Linked Network

At a molecular level, natural rubber is made of long, tangled polymer chains that can slide past one another. The heat and sulfur act as a catalyst, creating strong sulfur cross-links that act like bridges, tying these individual chains together into a unified, net-like structure.

The Resulting Properties

This new molecular structure locks the polymer chains in place. It prevents them from moving independently, resulting in a material that is vastly superior. The rubber becomes more pliable, durable, and weather-resistant, and it maintains its shape and flexibility across a wide range of temperatures.

Why Vulcanized Rubber is the Industry Standard

The properties created by vulcanization make it the go-to material for thousands of applications where reliability is essential.

Unmatched Durability for Footwear

In sneakers and boots, the vulcanized sole provides a unique combination of flexibility for comfort and toughness for wear resistance. Its waterproof nature also protects the foot from the elements.

Essential for Demanding Applications

For products like car tires, hoses, and seals, there is no substitute. The material must withstand constant friction, high temperatures, and extreme pressure without degrading, a feat only possible thanks to the stability provided by vulcanization.

Understanding the Trade-offs

While revolutionary, the process is not without its compromises. Understanding them is key to appreciating its role in manufacturing.

An Irreversible Process

Vulcanization is a "thermoset" process, meaning it is a one-way chemical reaction. Once the rubber is vulcanized, it cannot be melted down and easily reshaped. This makes recycling more complex compared to thermoplastic materials.

Dependence on Chemical Additives

The process relies on specific chemical agents beyond just sulfur. While modern manufacturing has refined these formulas, the production and disposal of these chemicals carry environmental considerations.

How to Apply This to Your Product

Choosing a material always depends on the primary goal of the product.

- If your primary focus is extreme durability and weather resistance: Vulcanized rubber is the definitive choice for applications like tires, industrial hoses, or rugged outdoor footwear.

- If your primary focus is flexibility, grip, and cost-effective production: The process is ideal for creating the classic, durable soles found on sneakers and casual shoes.

Ultimately, vulcanization transforms a flawed natural material into one of the most reliable and versatile engineering components in the modern world.

Summary Table:

| Property | Natural Rubber | Vulcanized Rubber |

|---|---|---|

| Durability | Low; soft and sticky | High; tough and resilient |

| Temperature Resistance | Poor; brittle when cold | Excellent; stable across a wide range |

| Elasticity / Shape Memory | Low; deforms easily | High; returns to original shape |

| Key Applications | Limited practical use | Tires, shoe soles, hoses, seals |

Ready to integrate high-performance vulcanized rubber into your product line?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our expertise in vulcanization ensures your products offer unmatched durability, flexibility, and weather resistance.

Contact our team today to discuss how we can manufacture the perfect vulcanized footwear for your market needs.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Wholesale Lightweight Cushioned Athletic Sneakers for Custom Bulk Production

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality