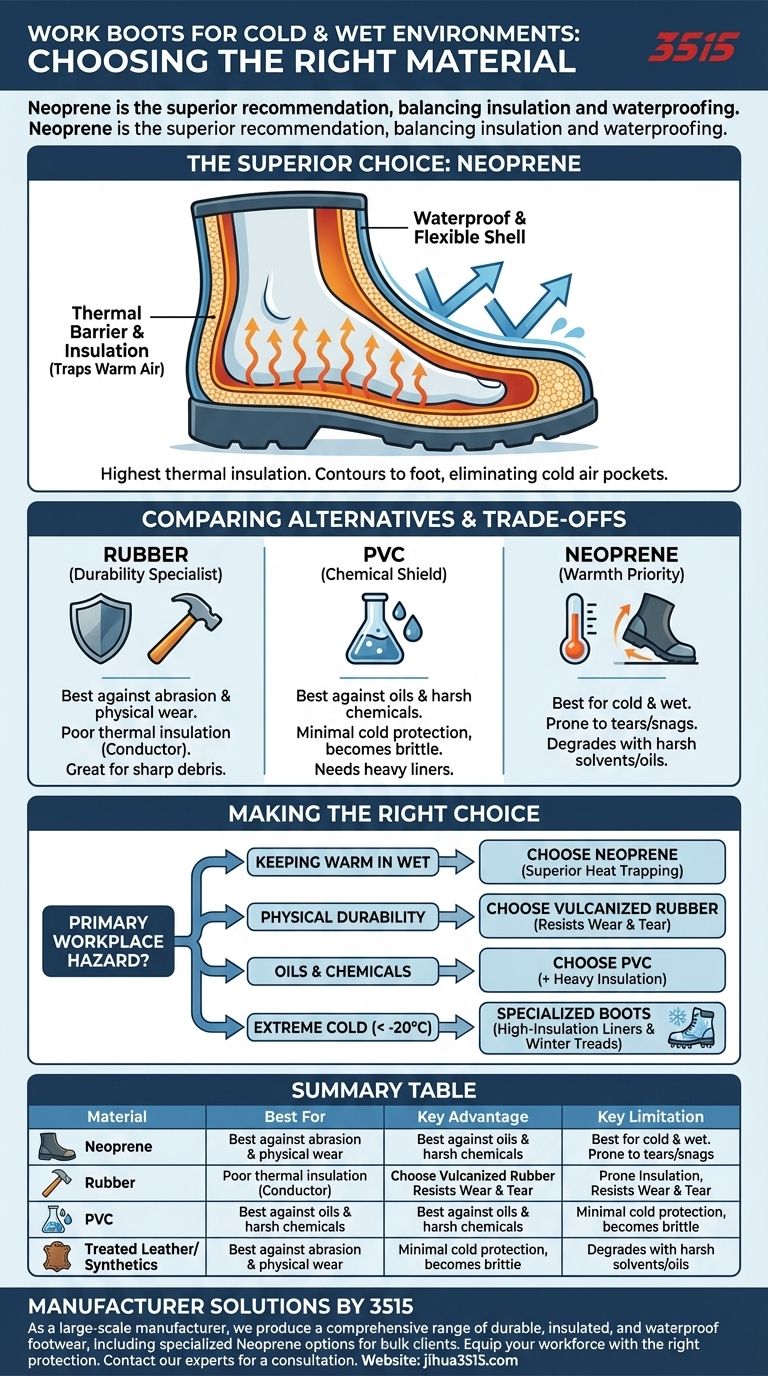

For work environments that are both cold and wet, Neoprene is the superior material recommendation. It offers the highest level of thermal insulation among common boot materials while providing the necessary waterproofing. Unlike standard rubber, Neoprene traps body heat effectively and contours to the foot and calf, ensuring you remain warm and mobile even in freezing conditions.

Core Insight While rubber offers durability and PVC resists chemicals, neither provides adequate protection against freezing temperatures. Neoprene is the only material that successfully bridges the gap between waterproof protection and active thermal retention for cold climates.

The Science of Thermal Protection

Superior Insulation

When temperatures drop, the primary challenge is not just keeping water out, but keeping heat in. Neoprene excels here because it is an insulating foam rubber.

It creates a thermal barrier that traps warm air against your skin. Standard rubber or PVC acts as a conductor, often allowing the cold from the outside to transfer through to your foot.

Flexibility and Heat Retention

Neoprene is inherently flexible. It closely follows the contours of your feet and calves.

This snug fit eliminates large air pockets where cold air typically accumulates in looser-fitting boots. This flexibility also maintains comfort and range of motion, which is often lost with rigid winter footwear.

Comparing the Alternatives

Rubber: The Durability Specialist

Rubber, particularly when vulcanized, is the most durable option available. It is highly resistant to physical wear, tears, and abrasion.

It provides resistance to specific hazards like ammonia, animal waste, and fertilizers. However, its thermal insulation is significantly lower than Neoprene, making it a secondary choice if warmth is the priority.

PVC: The Chemical Shield

PVC offers the best protection against oils, animal fats, and harsh chemicals. It is the go-to material for industrial chemical handling.

However, PVC provides minimal protection against the cold. It is unsuitable for freezing conditions as it offers little insulation and can become stiff or brittle in low temperatures.

Treated Leather and Synthetics

For less extreme wet conditions, treated leather or synthetic tactical boots can be effective. These are often lighter and more breathable than rubber boots.

To function in the cold, however, they must be paired with specific linings, such as wool or synthetic insulation, to manage moisture and provide warmth.

Understanding the Trade-offs

Durability vs. Warmth

While Neoprene is the warmest option, it is generally more prone to tears and snagging than vulcanized rubber.

If your work environment involves walking through sharp debris, scrap metal, or dense underbrush, the soft exterior of a Neoprene boot may be compromised. In these cases, a rubber boot with an added thermal liner may be a safer compromise.

Chemical Incompatibility

Neoprene offers resistance to mild acids, but it degrades when exposed to harsh solvents or oils.

If you work in an environment with frequent oil or chemical spills, Neoprene may break down prematurely. You may need to prioritize the chemical resistance of PVC and rely on heavy, separate thermal socks for warmth.

Considerations for Extreme Environments

Sub-Zero Requirements

If you are operating in extreme cold (below -20°C), material choice alone is insufficient. You require boots with high-insulation linings specifically rated for those temperatures.

Traction Control

In freezing wet conditions, ice is a constant hazard. Look for specialized outsoles with tread designs similar to winter tires. These provide essential grip on ice and snow that standard work boot treads cannot offer.

Making the Right Choice for Your Goal

Select your footwear based on the specific primary hazard of your worksite.

- If your primary focus is keeping warm in wet conditions: Choose Neoprene for its superior ability to trap heat and contour to the body.

- If your primary focus is physical durability and abrasion resistance: Choose Vulcanized Rubber, as it withstands wear and tear better than cellular foam materials.

- If your primary focus is protection against oils and chemicals: Choose PVC, but ensure you add significant external insulation (liners/socks) to combat the cold.

- If your primary focus is extreme cold (below -20°C): Choose below-the-knee lace-up boots with heavy integrated insulation and winter-tire grade treads.

Ultimately, the best boot is one that balances thermal regulation with the specific physical hazards of your daily terrain.

Summary Table:

| Material | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Neoprene | Cold & Wet Conditions | Superior thermal insulation & flexibility | Less durable, prone to tears/snags |

| Rubber | Durability & Abrasion | High resistance to wear, tears, and ammonia | Poor thermal insulation |

| PVC | Chemical Resistance | Best protection against oils and harsh chemicals | Minimal cold protection, can become brittle |

| Treated Leather/Synthetics | Less Extreme Wet Conditions | Lightweight and breathable | Requires added insulation for cold |

Struggling to find the right work boots for your cold, wet environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of insulated and waterproof shoes and boots, including specialized Neoprene options designed to keep your teams warm, dry, and productive.

Let us help you equip your workforce with the right protection. Contact our experts today for a consultation on the best footwear solutions for your specific needs and hazards.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

People Also Ask

- Which type of boot offers better fit retention over time? The Answer Lies in Adjustable Design

- What is the necessity of seamless lining in footwear? Enhance Comfort and Clinical Safety in Professional Boots

- Why are structural firefighting boots essential for firefighter safety? The Foundation of Protection and Performance

- Why is electrical hazard protection required on some job sites? Essential Safety for High-Risk Environments

- How does routine boot maintenance benefit workplace safety? Proactive PPE Protection for Your Workforce

- How do the soles and midsoles of firefighter boots enhance safety? Ensure Foot Protection from the Ground Up

- What materials are used in composite toe work boots, and what are their advantages? Get Lightweight, Non-Conductive Safety

- What are the benefits of shock-absorbing soles? Reduce Joint Strain and Fatigue