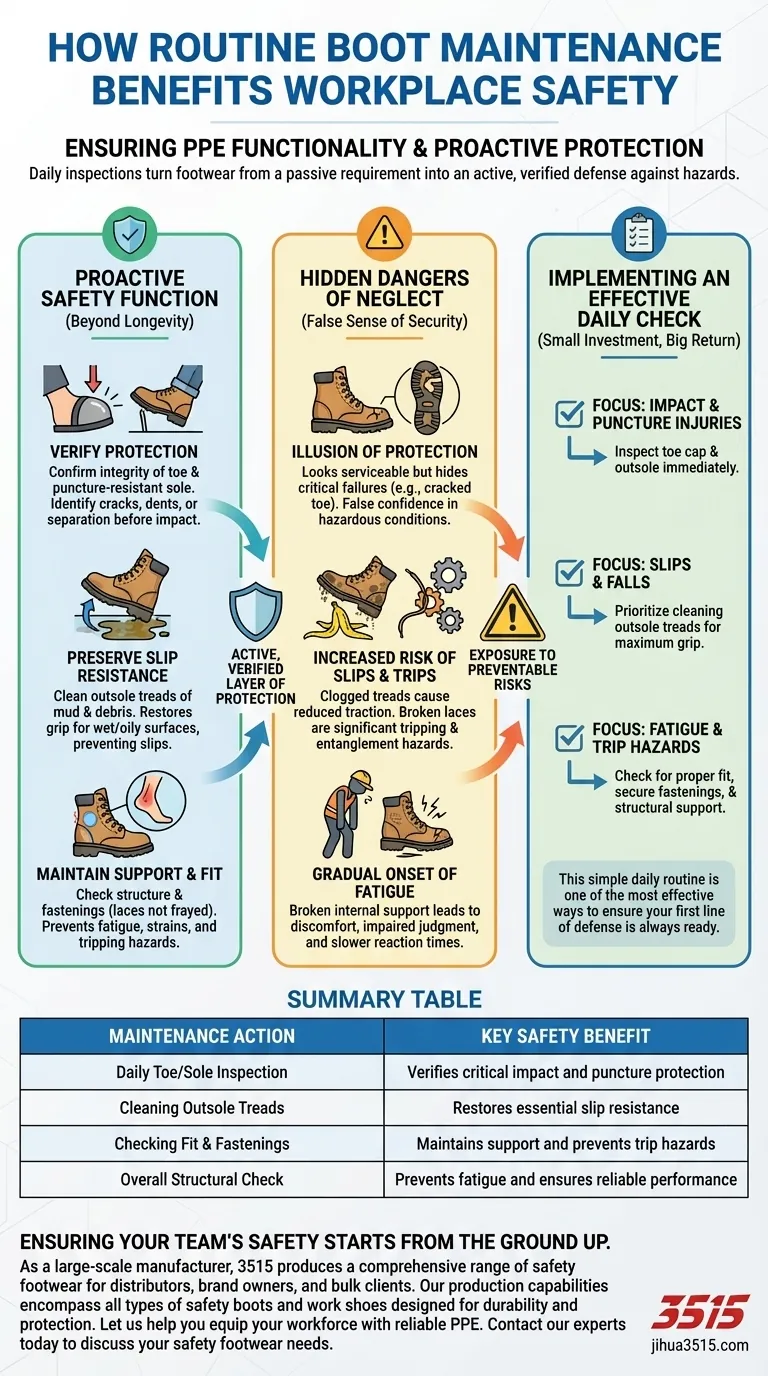

Routine boot maintenance directly benefits workplace safety by ensuring the protective features of your Personal Protective Equipment (PPE) are fully functional. A brief, daily inspection proactively identifies wear, damage, and fit issues before they can fail during a critical moment, turning your footwear from a potential liability into a reliable defense against injury.

The core purpose of a daily boot check is not just to extend the equipment's lifespan, but to perform a critical safety inspection. This five-minute habit transforms footwear from a passive requirement into an active, verified layer of protection against specific workplace hazards.

Beyond Longevity: Maintenance as a Proactive Safety Function

Many view boot care through the lens of durability, but its most important function is safety assurance. A boot that appears intact can harbor hidden failures that compromise its protective capabilities entirely.

Verifying Toe and Sole Protection

The primary defenses of a safety boot are its protective toe and puncture-resistant sole. Daily checks are the only way to confirm their integrity.

A quick inspection can reveal cracks, dents, or separation in the toe cap area that would otherwise go unnoticed until an impact occurs. Likewise, checking the outsole for deep cuts or embedded sharp objects ensures the puncture-resistant layer hasn't been compromised.

Preserving Critical Slip Resistance

An outsole's grip depends entirely on its tread pattern and material. When treads become clogged with mud, grease, or debris, their ability to provide traction on wet or oily surfaces is severely diminished.

A simple daily cleaning restores the boot's designed slip resistance, which is a critical safety feature in environments like construction sites, warehouses, and landscaping where slips and falls are common accidents.

Maintaining Structural Support and Fit

Proper ankle support and a secure fit help reduce fatigue and prevent musculoskeletal strain over a long shift. Maintenance includes checking the boot's overall structure and its fastening system.

For boots with laces, this means ensuring they are not frayed and can be tied securely to prevent tripping hazards. For pull-on boots, it means checking that the boot still fits snugly enough to provide necessary ankle support and stability.

The Hidden Dangers of Neglected Footwear

Ignoring boot maintenance creates a false sense of security and exposes workers to preventable risks. The danger lies not in what you can see, but in the unseen failures of neglected equipment.

The Illusion of Protection

A boot can look serviceable while hiding a critical failure, such as a cracked composite toe or a worn-through sole. This gives the wearer the confidence to work in hazardous conditions without any of the actual protection they rely on.

Increased Risk of Slips, Trips, and Falls

Dirty, clogged outsoles are a direct cause of reduced traction. Similarly, a broken or loose lace presents a significant and well-known tripping and entanglement hazard, especially when working around machinery.

The Gradual Onset of Fatigue

When a boot's internal support structures break down, it no longer fits or supports the foot correctly. This leads to increased fatigue, which can impair judgment and slow reaction times, contributing to other accidents.

Implementing an Effective Boot Safety Check

A daily inspection is a small investment of time that provides a significant return in personal safety. Tailor your focus to the primary risks of your environment.

- If your primary focus is preventing acute impact and puncture injuries: Immediately inspect the toe cap for damage and the outsole for deep cuts or embedded objects.

- If your primary focus is avoiding slips and falls: Prioritize cleaning the outsole treads of all debris to ensure maximum grip and traction.

- If your primary focus is minimizing fatigue and trip hazards: Check for proper fit, secure fastenings, and signs of degrading structural or ankle support.

This simple, daily routine is one of the most effective ways to ensure your first line of defense is always ready to protect you.

Summary Table:

| Maintenance Action | Key Safety Benefit |

|---|---|

| Daily Toe/Sole Inspection | Verifies critical impact and puncture protection |

| Cleaning Outsole Treads | Restores essential slip resistance |

| Checking Fit & Fastenings | Maintains support and prevents trip hazards |

| Overall Structural Check | Prevents fatigue and ensures reliable performance |

Ensure your team's safety starts from the ground up. As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work shoes designed for durability and protection. Let us help you equip your workforce with reliable PPE. Contact our experts today to discuss your safety footwear needs.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the key features of a work boot? Essential Protection for Hazardous Work Environments

- What types of safety toe boots are available? Find the Perfect Fit for Your Job's Hazards

- What types of safety toe boots are available for different job requirements? Choose the Right Protection for Your Work

- Is there any truth to the myth about steel toe boots causing toe injuries upon impact? Debunking Common Safety Concerns

- What is the importance of choosing the right size for steel toe boots? Avoid Injury and Boost Productivity