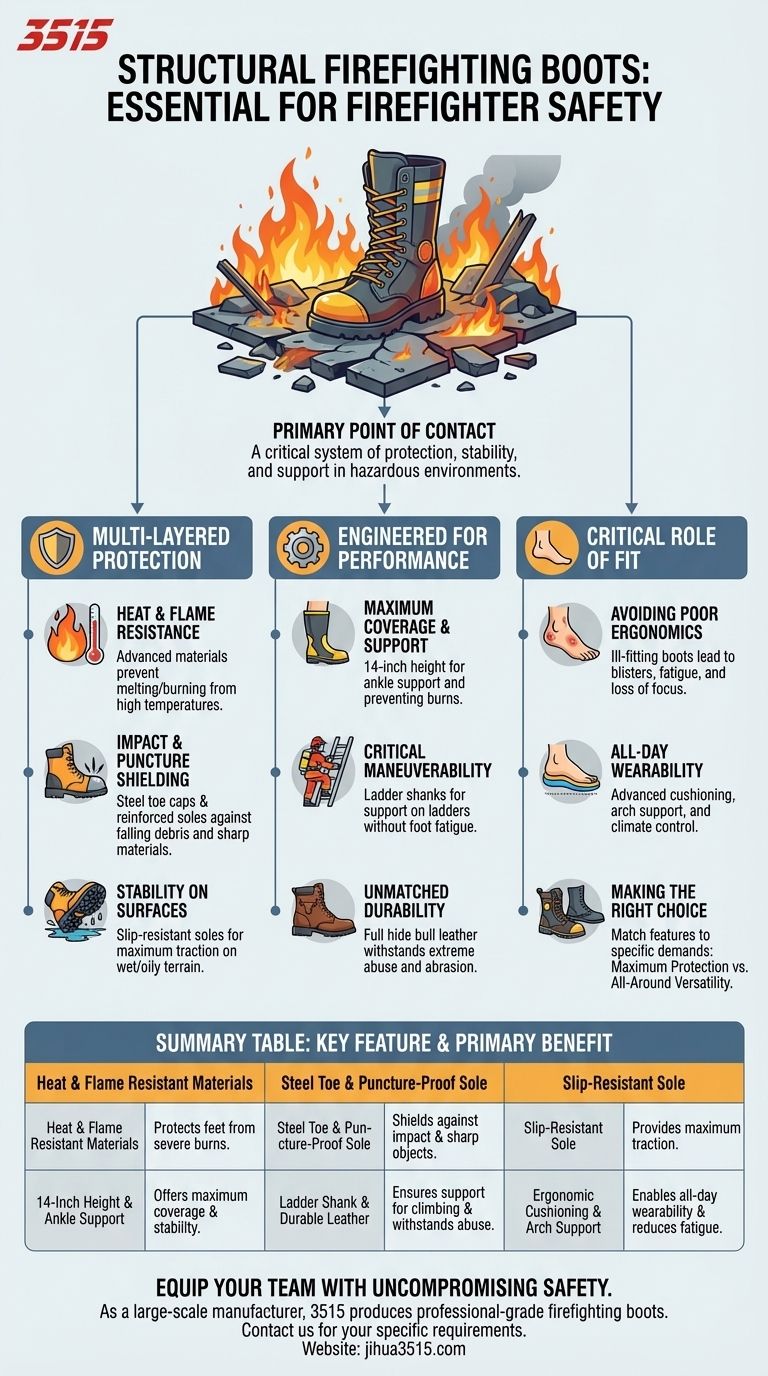

At their core, structural firefighting boots are essential because they are a firefighter's primary point of contact with a hazardous and unpredictable environment. They serve as a critical system of protection, engineered not only to shield the wearer from extreme heat, falling debris, and sharp objects but also to provide the stability and support necessary to perform life-saving tasks under immense pressure.

Beyond simply shielding from immediate harm, the design of a structural firefighting boot is a critical balance of robust protection, functional support, and ergonomic comfort. This balance ensures a firefighter can maintain peak performance without compromise, as failure in any one area can have catastrophic consequences.

A Foundation of Multi-Layered Protection

The primary role of a structural boot is to create an impenetrable barrier between the firefighter and the ground-level dangers inherent in a fire scene. This protection is not a single feature but a combination of specialized components.

Resisting Extreme Heat and Flame

Structural boots are built with advanced, heat-resistant materials. These compounds are engineered to prevent melting or burning even when exposed to the high temperatures found in a structure fire, safeguarding the firefighter's feet from severe burns.

Shielding from Impact and Puncture

Fire scenes are littered with hazardous debris. To counter this, boots are equipped with steel toe caps for impact resistance against falling objects and reinforced soles to protect against punctures from nails, glass, and other sharp materials on the ground.

Ensuring Stability on Unpredictable Surfaces

A loss of footing can be fatal. Firefighting boots feature aggressive, slip-resistant soles designed to provide maximum traction on wet, oily, or uneven surfaces, ensuring stable movement and preventing dangerous falls.

Engineered for Functional Performance

Protection is only effective if it allows the firefighter to do their job. The design of these boots goes beyond passive defense to actively support the physical demands of firefighting.

Maximizing Coverage and Support

Most structural boots are 14 inches high, a specific design choice to provide maximum protection to the foot, ankle, and lower leg. This high ankle support is crucial for preventing burns and providing stability when navigating treacherous terrain.

Enabling Critical Maneuverability

Firefighting requires climbing, crawling, and carrying heavy loads. Boots incorporate features like specialized ladder shanks that provide the rigidity and support needed to safely ascend and descend ladders without foot fatigue.

Built for Unmatched Durability

These boots must withstand extreme abuse. The use of materials like full hide bull leather ensures the boot maintains its structural integrity and protective qualities through repeated exposure to heat, water, and abrasion.

Understanding the Trade-offs: The Critical Role of Fit

A boot's protective features are rendered useless if it hinders the wearer's ability to move or causes debilitating pain. Comfort is not a luxury; it is a critical component of safety and performance.

The High Cost of Poor Ergonomics

Ill-fitting boots are a direct threat to a firefighter's effectiveness. They can quickly lead to blisters, extreme fatigue, and a loss of focus, all of which compromise safety and performance during long, demanding shifts.

The Importance of All-Day Wearability

Modern boots incorporate features like advanced cushioning, arch support, and climate control systems. These elements ensure breathability and support, helping firefighters maintain their energy and focus throughout an incident.

Making the Right Choice for Your Goal

Selecting the correct boot involves matching its specific features to the most likely demands of the job.

- If your primary focus is maximum protection in intense structural fires: Prioritize boots with the highest heat-resistance ratings, puncture-proof soles, and durable full-leather construction.

- If your primary focus is all-around versatility and extended use: Look for models that balance robust protection with advanced ergonomic features like superior cushioning, arch support, and integrated climate control systems.

Ultimately, your boots are the foundation upon which every action on the fire ground is built.

Summary Table:

| Key Feature | Primary Benefit |

|---|---|

| Heat & Flame Resistant Materials | Protects feet from severe burns in high temperatures. |

| Steel Toe & Puncture-Proof Sole | Shields against impact from falling debris and sharp objects. |

| Slip-Resistant Sole | Provides maximum traction on wet, oily, or uneven surfaces. |

| 14-Inch Height & Ankle Support | Offers maximum coverage and stability for the lower leg. |

| Ladder Shank & Durable Leather | Ensures support for climbing and withstands extreme abuse. |

| Ergonomic Cushioning & Arch Support | Enables all-day wearability, reducing fatigue and maintaining focus. |

Equip Your Team with Uncompromising Safety

As a large-scale manufacturer, 3515 produces a comprehensive range of professional-grade footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, including high-performance structural firefighting boots engineered for maximum protection, durability, and comfort.

We help you ensure the safety and effectiveness of first responders. Contact us today to discuss your specific requirements and discover how our manufacturing expertise can deliver the reliable footwear your customers depend on.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are the key features of engineer boots? Discover Their Unmatched Durability & Iconic Style

- What material is recommended for workers needing long-term wear, especially those with plantar fasciitis or diabetes? PU for Superior Comfort

- What additional safety features can be found in Chemical Resistant boots? Essential Multi-Hazard Protection

- What materials are used for work boot outsoles? Choose the Right Material for Your Job

- What are the properties of rubber as an upper material for work boots? A Guide to Waterproof Durability vs. Comfort

- What should you consider when choosing cowboy boots? Find Your Perfect Fit for Work or Style

- How do composite toe work boots handle moisture? Stay Dry and Comfortable in Wet Conditions

- What are the main advantages of pull-on work boots? Unlock Speed, Safety & Durability