At their core, composite toe work boots are crafted from a blend of non-metallic materials, most commonly Kevlar, carbon fiber, plastic, or fiberglass. These materials are engineered to provide a safety cap that is significantly lighter than traditional steel, does not conduct electricity or temperature, and allows passage through metal detectors without issue.

The central takeaway is that composite toe caps offer modern, lightweight protection that excels in work environments where metal is a liability—whether due to electrical hazards, extreme temperatures, or security screening requirements.

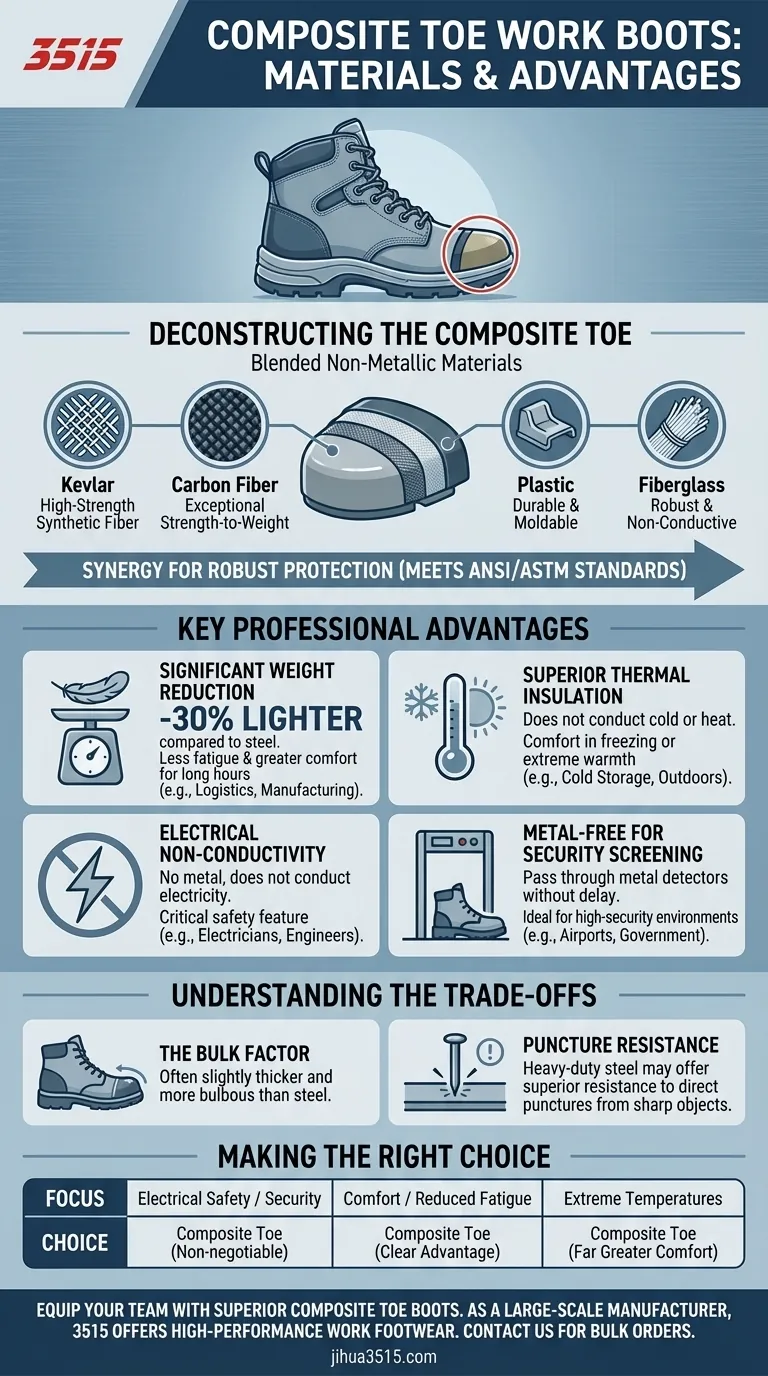

Deconstructing the "Composite" in Composite Toe

To understand the advantages of these boots, we must first understand the materials that give them their name. The term "composite" simply refers to something made from several different materials combined.

The Core Materials: Kevlar, Carbon Fiber, and More

The protective cap in a composite toe boot is typically formed from Kevlar, a high-strength synthetic fiber known for its use in ballistics protection.

Other common materials include carbon fiber, which provides exceptional strength-to-weight ratio, as well as durable plastics and fiberglass. These elements are layered and molded to create the protective toe cap.

How They Achieve Protection

Unlike a solid piece of steel, these materials are combined to create a cap that meets the same ANSI/ASTM safety standards for impact and compression as steel toe boots. The synergy between the materials allows for robust protection without the associated weight or conductivity of metal.

Key Advantages in a Professional Context

The choice to use composite materials is deliberate, offering distinct advantages that are critical in many modern workplaces. Each benefit directly addresses a specific professional need.

Advantage 1: Significant Weight Reduction

Composite toe caps are approximately 30% lighter than their steel counterparts. For professionals who spend long hours on their feet in fields like logistics or manufacturing, this weight reduction directly translates to less fatigue and greater comfort over a full workday.

Advantage 2: Superior Thermal Insulation

A primary benefit of non-metallic materials is their inability to conduct temperature. Composite toes will not get cold in freezing environments or heat up in extreme warmth, providing superior comfort for anyone working outdoors or in climate-controlled facilities like cold storage.

Advantage 3: Electrical Non-Conductivity

Because they contain no metal, composite toe boots do not conduct electricity. This is a critical safety feature for electricians, engineers, and any personnel working near live circuits or in environments where static discharge is a concern.

Advantage 4: Metal-Free for Security Screening

The absence of metal makes these boots ideal for workers in high-security environments, such as airports, government buildings, or sensitive manufacturing plants. They allow you to pass through metal detectors without the delay and inconvenience of removing your footwear.

Understanding the Trade-offs

While the benefits are significant, an objective assessment requires acknowledging the inherent trade-offs of the technology.

The Bulk Factor

To achieve the required safety rating, composite toe caps are often slightly thicker and more bulbous than steel caps. While this rarely affects comfort, it can result in a boot with a slightly bulkier profile at the toe.

Puncture Resistance Considerations

While composite materials excel at resisting impact and compression, some heavy-duty steel options may offer superior resistance against direct punctures from sharp objects like nails. This is a critical factor to consider for demolition or heavy construction sites where such hazards are common.

Making the Right Choice for Your Work Environment

Selecting the proper safety boot is a matter of aligning the material's properties with the specific demands of your job.

- If your primary focus is electrical safety or passing through metal detectors: Composite toe is the definitive, non-negotiable choice for its non-conductive and metal-free properties.

- If your primary focus is all-day comfort and reduced fatigue: The significant weight savings of a composite toe boot will provide a clear advantage over a long shift.

- If your primary focus is working in extreme hot or cold temperatures: The thermal insulation of composite materials will offer far greater comfort than conductive steel.

- If your primary focus is maximum protection in a hazardous construction zone: You must weigh the benefits of composite against the potentially higher puncture resistance of some steel toe options.

Ultimately, understanding these materials empowers you to choose the precise tool that enhances both your safety and your performance on the job.

Summary Table:

| Material | Key Advantage | Ideal For |

|---|---|---|

| Kevlar / Carbon Fiber | High strength-to-weight ratio | Reducing fatigue, all-day wear |

| Plastic / Fiberglass | Non-conductive, thermal insulator | Electrical work, extreme temperatures |

| Composite Blend | Metal-free | Passing through security checkpoints |

Ready to equip your team with superior composite toe safety boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, including advanced composite toe models designed for maximum comfort and protection.

We can help you provide the right safety solution for electrical, construction, and security-sensitive environments.

Contact our expert team today to discuss your needs and request a quote.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How does the slip resistance of industrial safety shoes protect workers during Genset maintenance? Prevent Oil Slips

- How do professional safety shoes protect the musculoskeletal system? Enhance Worker Ergonomics & Reduce Fatigue

- What are the primary protective functions of professional-grade safety shoes? Enhance Safety in Heavy Industry

- What specific protective features are required for safety shoes in high-temperature rotary kiln maintenance areas?

- Why is it necessary to equip operators with professional safety shoes in a flour milling workshop? Prevent Slip Hazards