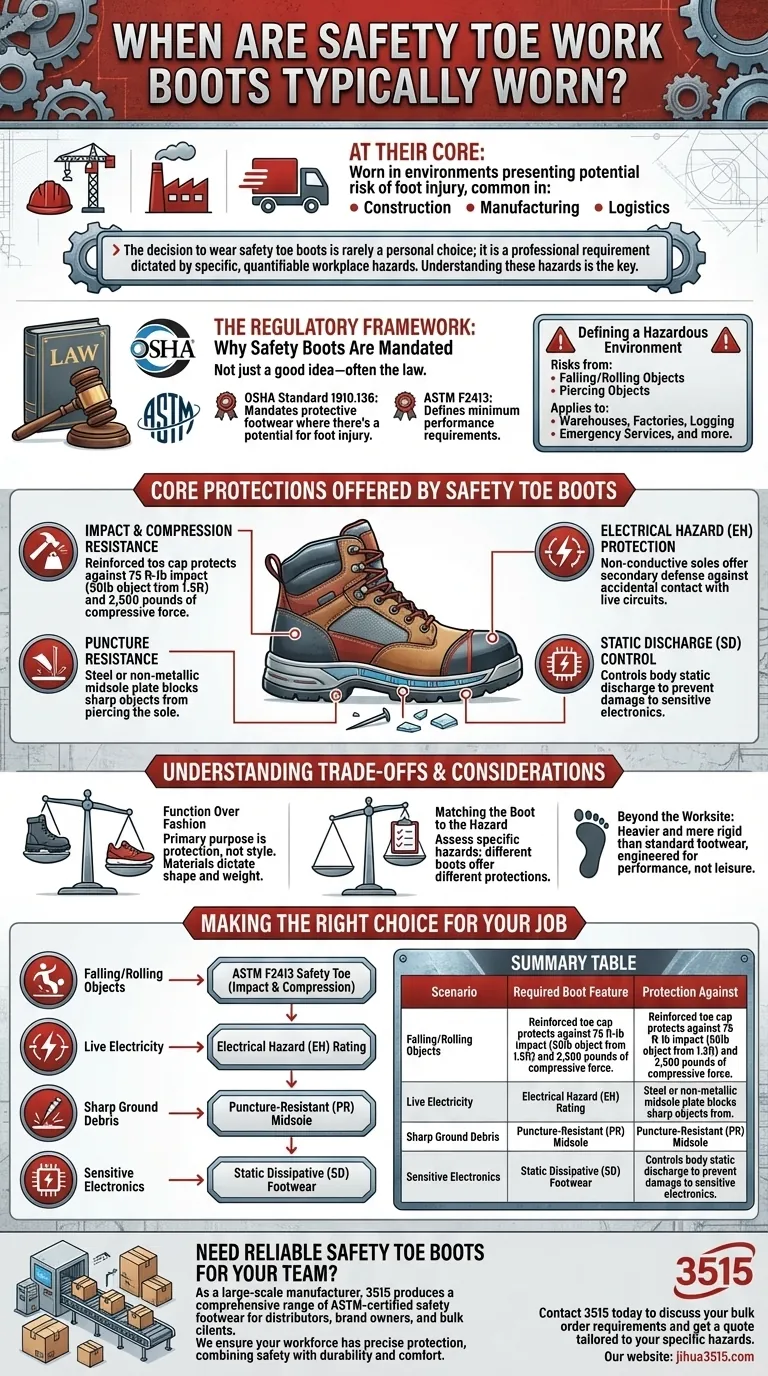

At their core, safety toe work boots are worn whenever a work environment presents a potential risk of foot injury. Their use is most common in professions governed by safety regulations, such as construction, manufacturing, and logistics, where hazards from falling objects, compression, or punctures are a daily reality.

The decision to wear safety toe boots is rarely a personal choice; it is a professional requirement dictated by specific, quantifiable workplace hazards. Understanding these hazards is the key to recognizing when this essential protection is necessary.

The Regulatory Framework: Why Safety Boots Are Mandated

The use of safety toe footwear isn't just a good idea—it's often the law. Regulatory bodies establish clear standards to remove ambiguity and ensure worker protection.

OSHA and ASTM Standards

The primary driver for safety boot usage in the United States is OSHA Standard 1910.136. This rule mandates that employers require protective footwear in any environment with a potential for foot injury.

To define what qualifies as "protective," OSHA often refers to consensus standards like ASTM F2413. This standard specifies the minimum performance requirements for footwear to protect against a variety of workplace dangers.

Defining a "Hazardous Environment"

An environment is considered hazardous if it includes risks of injury from falling or rolling objects, or from objects that could pierce the sole of the shoe. This applies to a wide range of industries, from warehouses and factories to logging and emergency services.

Core Protections Offered by Safety Toe Boots

Safety boots are multi-functional tools designed to mitigate a precise set of risks. The "safety toe" is just the beginning of the protection they offer.

Impact and Compression Resistance

The most fundamental feature is the reinforced toe cap. Per ASTM standards, it must protect the foot from a 75 foot-pound impact, equivalent to a 50-pound object dropped from about 1.5 feet.

The toe cap must also withstand 2,500 pounds of compressive force, protecting the foot from being crushed by rolling equipment or heavy materials.

Puncture Resistance

Many safety boots include a steel or non-metallic midsole plate. This feature is critical in environments where sharp objects like nails, scrap metal, or glass could pierce the boot's sole and cause a severe foot injury.

Electrical Hazard Protection

Specialized safety boots are rated for Electrical Hazard (EH) protection. These are designed with non-conductive soles and heels to offer a secondary layer of defense against accidental contact with live electrical circuits.

Static Discharge Control

In environments with sensitive electronics, other boots are designed to control static discharge from the body. This prevents a static shock from damaging delicate components, making them essential for certain manufacturing and technology sectors.

Understanding the Trade-offs and Considerations

While essential, safety footwear is purpose-built equipment, and it's important to understand the associated considerations.

Function Over Fashion

Although modern designs have improved aesthetics, the primary purpose of a safety boot is protection, not style. The reinforcement materials required by safety standards dictate the boot's shape and weight.

Matching the Boot to the Hazard

Not all safety boots are the same. A boot designed for EH protection may not have a puncture-resistant sole. It is crucial to assess all potential hazards in your specific environment and select a boot that provides comprehensive coverage.

Beyond the Worksite

While the concealed reinforcement allows some safety boots to be worn in casual settings, they are fundamentally heavier and more rigid than standard footwear. They are engineered for performance and durability under stress, not for leisure.

Making the Right Choice for Your Job

Selecting the correct boot depends entirely on the specific risks you face.

- If your primary focus is protection from falling or rolling objects: Any ASTM-rated safety toe boot will provide the necessary impact and compression resistance.

- If you work around live electricity: You must select a boot explicitly marked with an "EH" rating for electrical hazard protection.

- If your environment has sharp ground debris: Prioritize a boot with a puncture-resistant (PR) midsole to protect the bottom of your feet.

- If you work with sensitive electronics: Look for Static Dissipative (SD) footwear designed to prevent the buildup of static electricity.

Ultimately, choosing to wear a safety toe boot is a critical assessment of risk, ensuring you have the right protection for the environment you work in.

Summary Table:

| Scenario | Required Boot Feature | Protection Against |

|---|---|---|

| Falling/Rolling Objects | ASTM F2413 Safety Toe | Impact & Compression |

| Sharp Ground Debris | Puncture-Resistant (PR) Midsole | Nails, Glass, Metal |

| Live Electrical Circuits | Electrical Hazard (EH) Rating | Accidental Shock |

| Sensitive Electronics | Static Dissipative (SD) | Component Damage |

Need Reliable Safety Toe Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear for distributors, brand owners, and bulk clients. We ensure your workforce has the precise protection they need—from impact-resistant toes to puncture-proof soles—combining safety with durability and comfort.

Contact 3515 today to discuss your bulk order requirements and get a quote tailored to your specific hazards.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What makes Chemical Resistant boots durable and reliable? A Guide to Multi-Layer Protection

- What factors contribute to the comfort and fit of work boots? Key Components for All-Day Support

- What is the required height for NFPA wildland fire boots? The Essential 8-Inch Safety Standard

- What material is recommended for harness boots? Choose the Right Protection for Your Work

- Why are slip-resistant soles important in mining boots? Prevent Slips and Falls in Hazardous Conditions

- How did moc toe boots originate? A Legacy of Workwear Durability and Style

- What factors should be considered before purchasing oil field boots? Ensure Safety, Comfort, and Durability

- What is a metatarsal guard in Wellington work boots? Essential Protection for High-Risk Jobs