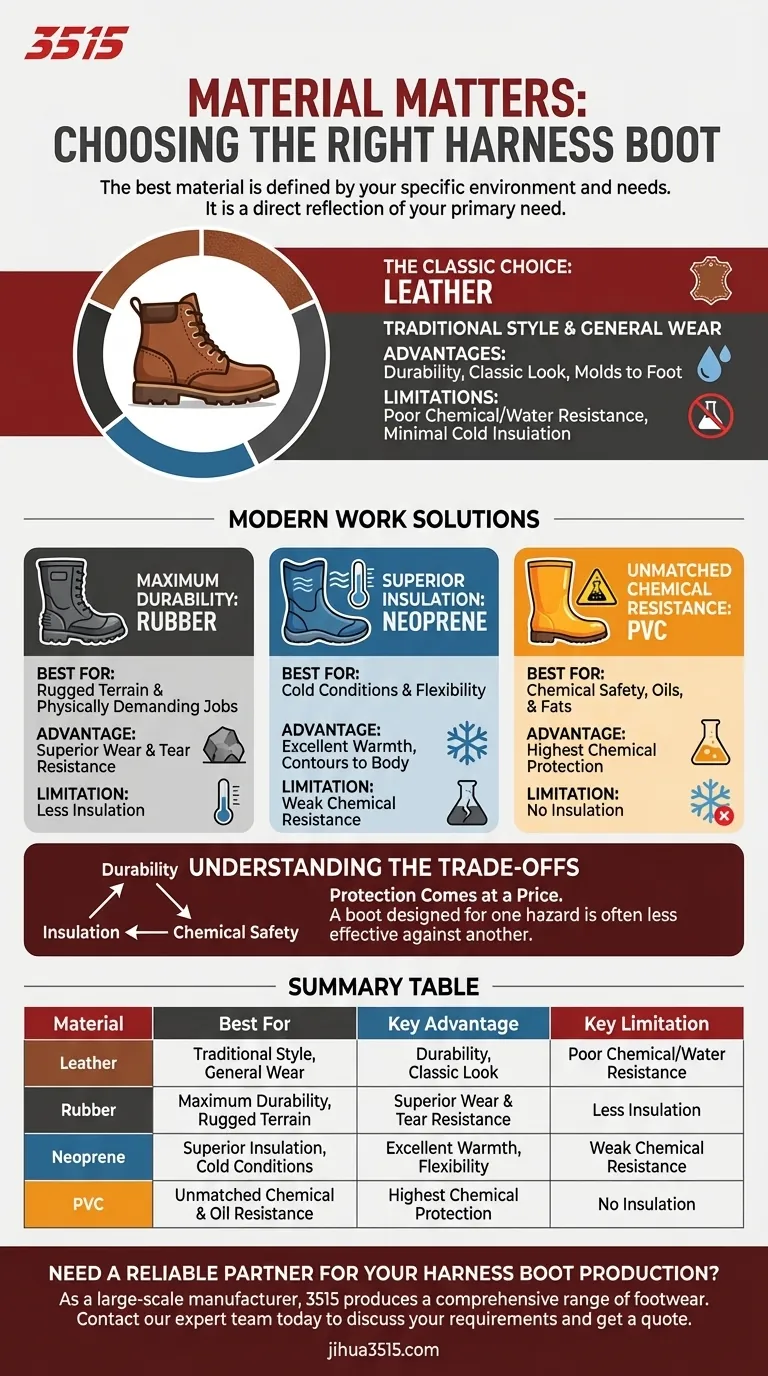

For traditional harness boots, the best material is always the toughest available leather. However, for heavy-duty work applications where specialized protection is crucial, materials like rubber, neoprene, and PVC each offer distinct advantages that leather cannot provide. The "best" material is therefore defined by your specific environment and needs.

The ideal boot material is not universal; it is a direct reflection of your primary need. Choose vulcanized rubber for maximum durability, neoprene for superior warmth, and PVC for essential chemical protection.

The Classic Choice: Leather

Why Leather Dominates Tradition

For the classic harness boot style, often associated with motorcycling or fashion, full-grain leather is the undisputed standard. It is valued for its exceptional durability, ability to mold to the wearer's foot, and timeless aesthetic. With proper care, a quality leather boot can last for decades.

Limitations in Modern Work Environments

While tough, leather offers poor resistance to harsh chemicals, oils, and animal waste. It is also not inherently waterproof and provides minimal insulation against extreme cold when compared to modern synthetic materials designed specifically for those hazards.

Choosing the Right Material for Your Work Environment

For Maximum Durability: Rubber

Rubber, particularly when vulcanized to reinforce its strength, is the most durable material for heavy-duty work boots. It offers the highest resistance to general wear, tear, and abrasion. This makes it the ideal choice for physically demanding jobs on rough terrain.

For Superior Insulation: Neoprene

Neoprene provides the best insulation against cold conditions by a significant margin. Its flexible structure traps warmth efficiently and contours closely to the foot and calf, preventing body heat from escaping.

For Unmatched Chemical Resistance: PVC

PVC offers the highest level of protection against a wide range of chemicals. It is highly resistant to oils, animal fats, fertilizers, and other corrosive substances, preventing skin irritation or harm from accidental exposure.

Understanding the Trade-offs

Protection Comes at a Price

Each material excels in one area by sacrificing performance in another. A boot designed for one hazard is often less effective against another.

Durability vs. Specialized Resistance

Rubber’s toughness makes it the longest-lasting material, but it offers less insulation than neoprene and weaker chemical resistance than PVC. While strong, both neoprene and PVC are more susceptible to tears and punctures, making them better suited for conditions where their specific protective property is the priority.

Insulation vs. Chemical Safety

Neoprene offers excellent warmth but only resists mild acids, making it a poor choice around harsher substances. Conversely, PVC's superior chemical protection comes with almost no insulation, rendering it unsuitable for freezing conditions.

Making the Right Choice for Your Needs

Your specific work environment and the primary hazard you face should be the deciding factors in your choice.

- If your primary focus is traditional style and general wear: Choose a boot made from high-quality, full-grain leather.

- If your primary focus is longevity in rugged physical conditions: Choose vulcanized rubber for its superior resistance to wear and tear.

- If your primary focus is warmth while working in the cold: Choose neoprene for its unmatched insulation properties.

- If your primary focus is safety around chemicals, oils, or fats: Choose PVC for the most comprehensive chemical protection.

Understanding these material distinctions ensures your boots serve as a reliable tool perfectly suited for your task.

Summary Table:

| Material | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Leather | Traditional Style, General Wear | Durability, Classic Look | Poor Chemical/Water Resistance |

| Rubber | Maximum Durability, Rugged Terrain | Superior Wear & Tear Resistance | Less Insulation |

| Neoprene | Superior Insulation, Cold Conditions | Excellent Warmth, Flexibility | Weak Chemical Resistance |

| PVC | Unmatched Chemical & Oil Resistance | Highest Chemical Protection | No Insulation |

Need a reliable partner for your harness boot production?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, from durable rubber work boots to insulated neoprene models and chemical-resistant PVC designs. We can help you source or manufacture the perfect harness boot for your market's specific needs.

Contact our expert team today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What is the primary function of industrial safety shoes in polymer recycling? Protect Against Machinery & Sharp Debris

- How do professional safety shoes protect the musculoskeletal system? Enhance Worker Ergonomics & Reduce Fatigue

- What specific protective features are required for safety shoes in high-temperature rotary kiln maintenance areas?

- Why is hydrophobic waterproof leather commonly utilized in the construction of fire safety boots? Essential Protection