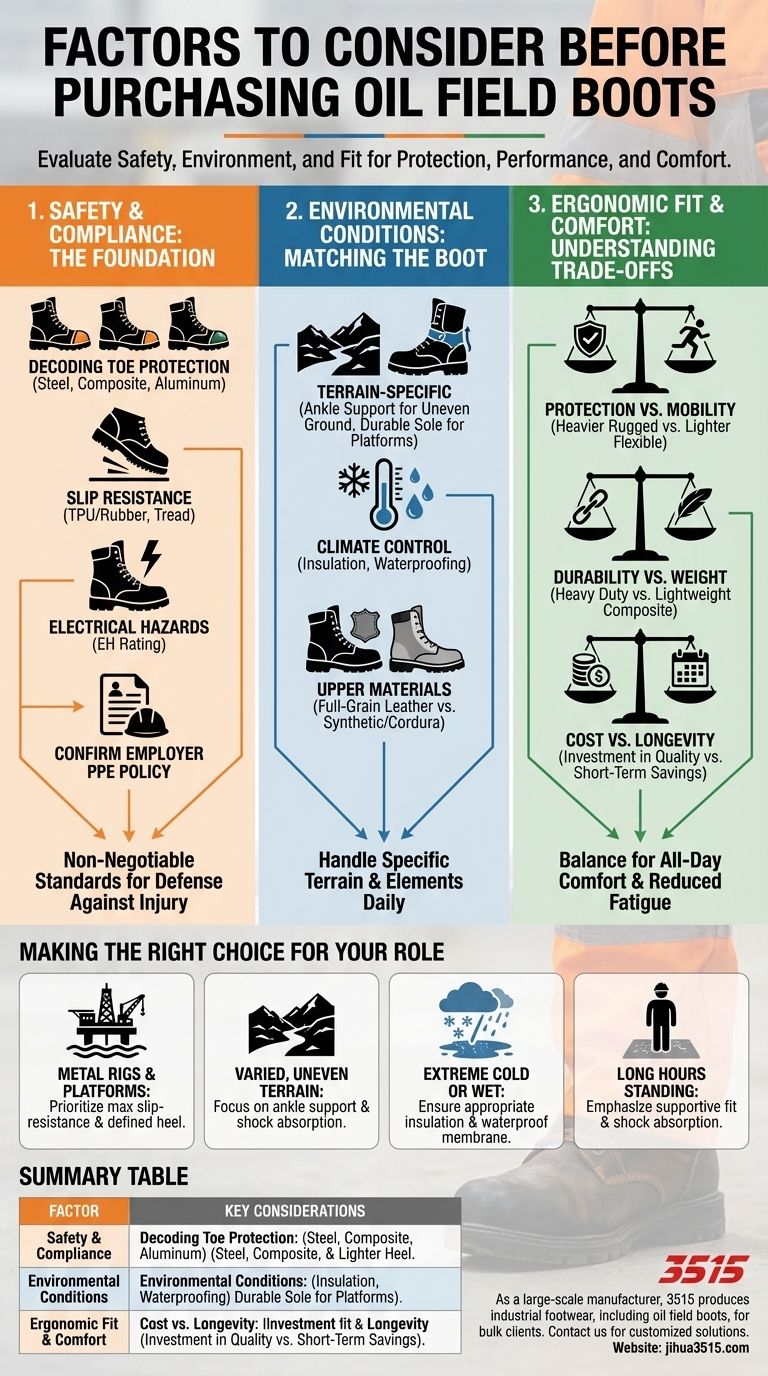

Before purchasing oil field boots, you must evaluate three core areas: the mandatory safety features required for your job, the specific environmental conditions you'll face, and the ergonomic fit necessary for all-day comfort and support. These elements work together to ensure your protection, prevent fatigue, and enhance your performance in a demanding workplace.

Your work boot is the most critical piece of personal protective equipment you own. The goal isn't just to find a boot that meets a safety checklist, but to find one that becomes a reliable tool, perfectly matched to your specific role, environment, and body.

The Non-Negotiable Foundation: Safety & Compliance

Your first priority must always be meeting the required safety standards. These features are not optional; they are your primary line of defense against serious injury.

Decoding Toe Protection

Most oil field jobs mandate safety toes. The choice of material—steel, composite, or aluminum—depends on your specific needs.

Steel toes offer the maximum protection against impact and compression, making them a traditional standard. However, they are heavy and conduct temperature.

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter, do not conduct electricity or temperature, and are ideal for environments with metal detectors.

Aluminum toes provide a lightweight alternative to steel but are typically thicker.

The Critical Role of Slip Resistance

Slips, trips, and falls are constant risks on slick surfaces like metal platforms, mud, and concrete. The boot's outsole is your point of contact with the ground.

Look for materials like Thermoplastic Polyurethane (TPU) or high-grade rubber, which provide excellent grip. The tread pattern is also crucial; deep lugs are better for mud, while finer patterns offer more surface contact on smooth, wet platforms.

Shielding Against Electrical Hazards

Many worksites present electrical risks. Boots with an Electrical Hazard (EH) rating are constructed with non-conductive soles and heels to offer a secondary source of protection against accidental contact with live electrical circuits.

Confirming Employer PPE Policy

Before you start shopping, always confirm your employer's specific Personal Protective Equipment (PPE) requirements. They may mandate certain toe types, sole materials, or other safety features. This step saves you time and ensures you are compliant from day one.

Matching the Boot to Your Environment

An oil field is not a single environment. Your boot must be equipped to handle the specific terrain and climate you will encounter daily.

Terrain-Specific Construction

The ground beneath your feet dictates the boot's structure. If you work on uneven, muddy, or sandy ground, a boot with excellent ankle support (typically 6-8 inches high) and a stable outsole is essential to prevent twists and sprains.

For those on concrete or metal platforms, a durable sole that resists abrasion and provides consistent traction is more important.

Climate Control: Insulation & Waterproofing

Exposure to the elements is a given. For cold climates, look for boots with insulation like Thinsulate, which provides warmth without excessive bulk.

In wet conditions, a waterproof membrane is non-negotiable to keep your feet dry and prevent discomfort or health issues.

The Upper Materials Debate

The "upper" is the part of the boot that covers your foot. Full-grain leather is incredibly durable and resistant to abrasion but requires a break-in period.

Synthetic materials like Cordura are lighter, more flexible, and often integrated with leather to provide a balance of durability and comfort right out of the box.

Understanding the Trade-offs

Selecting the perfect boot always involves balancing competing factors. Understanding these compromises is key to making an informed decision.

Protection vs. Mobility

Heavier, more rugged boots with features like steel toes and thick leather uppers offer maximum protection. However, this often comes at the cost of flexibility and can increase fatigue over a long shift.

Durability vs. Weight

The most durable materials are often the heaviest. A lighter boot made of composite materials might reduce fatigue but may not withstand the same level of abuse as its heavier leather counterpart. Assess your daily activity level to find the right balance.

Cost vs. Longevity

It can be tempting to choose a less expensive boot. However, a higher initial investment in a well-constructed boot from a reputable brand often translates to better materials, superior comfort, and a much longer lifespan, saving you money in the long run.

Making the Right Choice for Your Role

Use your specific job function as the final filter to select the ideal features for your needs.

- If you work primarily on metal rigs and platforms: Prioritize boots with maximum slip-resistance from a rubber or TPU outsole and a defined heel for climbing.

- If you frequently walk across varied, uneven terrain: Focus on excellent ankle support (a taller boot) and a shock-absorbing midsole to reduce fatigue.

- If you face extreme cold or wet conditions: Ensure your boots have the appropriate insulation level and a reliable waterproof membrane.

- If your role involves long hours of standing on hard surfaces: Emphasize a comfortable, supportive fit with a high-quality insole and shock absorption.

Choosing the right boot is a direct investment in your daily safety, comfort, and professional endurance.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Safety & Compliance | Toe protection (steel, composite, aluminum), slip-resistant soles, EH rating, employer PPE policy. |

| Environmental Conditions | Terrain (ankle support, outsole type), climate (insulation, waterproofing), upper material (leather, synthetic). |

| Ergonomic Fit & Comfort | Balance of protection vs. mobility, durability vs. weight, proper fit for all-day wear and fatigue prevention. |

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and oil field footwear, engineered to meet the highest standards of protection, durability, and comfort for demanding work environments. Let us help you equip your workforce with reliable, high-performance boots. Contact us today to discuss your specific needs and receive a customized solution.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What materials are used in protective work boots? A Guide to Durability & Safety

- Which material is recommended for work boots in cold, wet environments? Neoprene for Superior Warmth

- What are the advantages of synthetic/leather boots? Lightweight Comfort & Immediate Performance

- What are the key features of engineer boots? Discover Their Unmatched Durability & Iconic Style

- How is the midsole of light work boots constructed to maintain lightness? Achieve All-Day Comfort

- What are the advantages of the Powerwelt pull-on boots? Unmatched Convenience & Durability

- What are the different styles of women's work boots available? Find Your Perfect Fit for Safety & Comfort

- How do composite toe work boots provide protection without the weight of steel? Achieve Lighter, Safer Footwear