To be compliant with NFPA standards, a wildland fire boot must measure a minimum of 8 inches in height, taken from the bottom of the heel to the very top of the boot. This specific height is mandated to provide critical ankle support and prevent injuries on the unstable, rugged terrain inherent to wildland firefighting. However, this height requirement is just one component of a comprehensive safety standard.

The 8-inch height rule is a non-negotiable baseline for NFPA-compliant wildland boots. But true safety and effectiveness come from understanding this rule as part of a complete system that also dictates sole material, construction, and flame resistance.

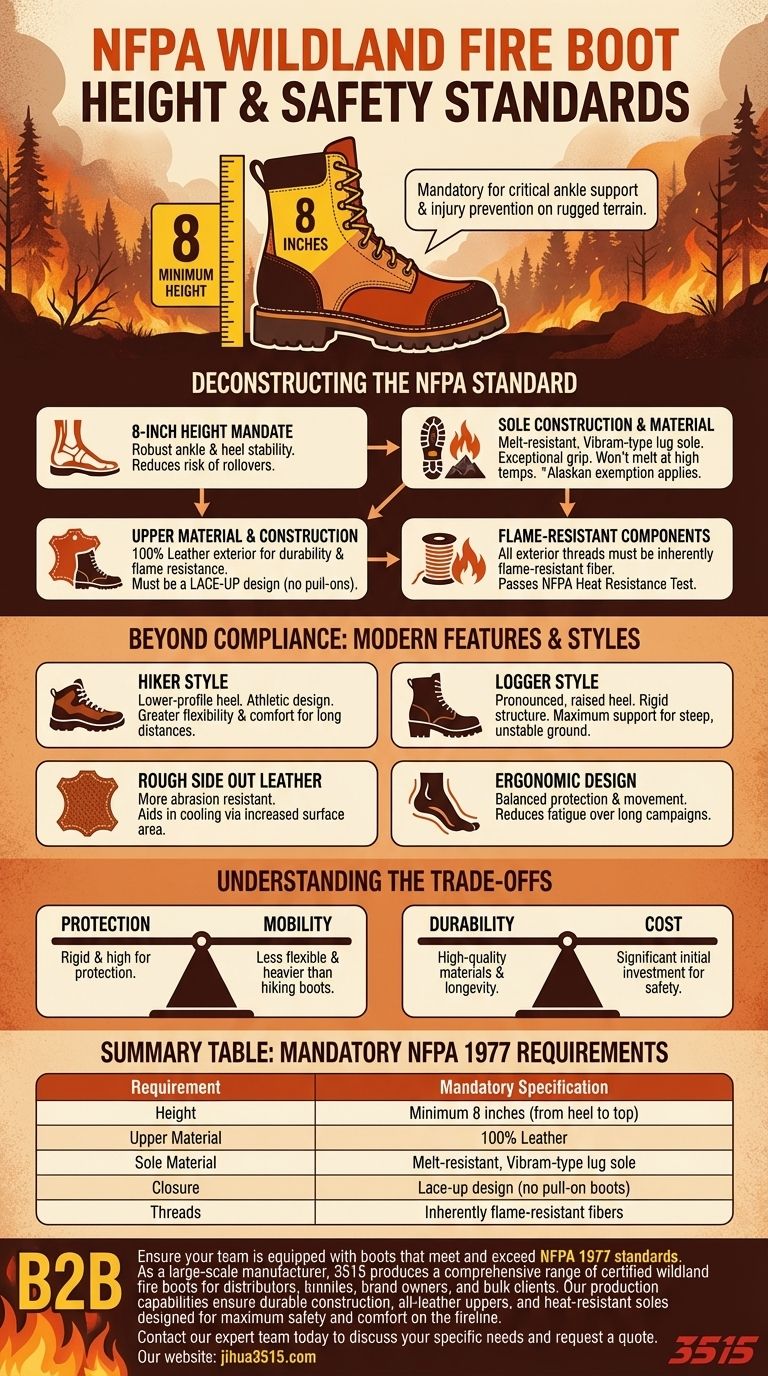

Deconstructing the NFPA Standard for Wildland Boots

The National Fire Protection Association (NFPA) establishes detailed requirements to ensure every piece of gear provides a minimum, verifiable level of safety. For wildland boots, these standards are built around protecting the firefighter from heat, rough terrain, and long hours of wear.

The 8-Inch Height Mandate

The primary reason for the 8-inch height requirement is to provide robust stability for the ankle and heel. Wildland firefighters constantly navigate steep, uneven, and unpredictable ground, where a rolled ankle can be a mission-ending, life-threatening injury. This taller design helps lock the ankle in place, reducing the risk.

Sole Construction and Material

NFPA standards require a melt-resistant, Vibram-type sole. This refers to a specific type of durable rubber lug sole known for its exceptional grip and high resistance to heat. The sole must not melt, delaminate, or lose integrity when exposed to the high ground temperatures common in a fire zone.

Notably, there is a specific exemption for Alaskan wildland firefighters from the requirement to have a Vibram-type sole, though the specific reasoning is not detailed in the standards.

Upper Material and Construction

The exterior upper of the boot must be made of 100% leather. Leather is specified for its natural durability, abrasion resistance, and inherent flame-resistant properties. Synthetic materials are not permitted on the exterior as they can melt when exposed to high heat.

Furthermore, all compliant boots must be a lace-up design. Pull-on boots, such as Wellingtons, are not acceptable under the standard because they cannot provide the secure, customized fit needed for ankle stability.

Flame-Resistant Components

Every detail is considered for heat resistance. All exterior threads used in the boot’s construction must be made of an inherently flame-resistant fiber. These threads must pass the NFPA's Thread Heat Resistance Test, ensuring they will not ignite, melt, or char under thermal exposure.

Beyond Compliance: Key Features of Modern Wildland Boots

While NFPA standards set the mandatory safety floor, boot manufacturers incorporate other features designed for performance and comfort during long campaigns.

Hiker vs. Logger Styles

Compliant boots are generally available in two styles. Logger boots typically have a more pronounced, raised heel and offer a very rigid structure for maximum support. Hiker-style boots often have a lower-profile heel and incorporate design elements from athletic footwear for greater flexibility and comfort over long distances.

The Role of "Rough Side Out" Leather

Many wildland boots use "rough side out" leather. This is not just a stylistic choice; the rougher texture is more resistant to abrasion and is believed to aid in cooling by increasing the surface area for moisture evaporation.

Design for Ergonomic Support

Ultimately, these boots are designed as a critical tool for an athletic endeavor. They must provide protection without unnecessarily impeding a firefighter's movement or causing debilitating fatigue over a 14-day assignment.

Understanding the Trade-offs

Choosing a boot always involves balancing competing priorities. Understanding these trade-offs is key to selecting the right tool for the job.

Protection vs. Mobility

The rigid construction, all-leather upper, and 8-inch height provide immense protection. However, this comes at the cost of the flexibility and light weight you might find in a commercial hiking boot. The break-in period for a new pair of wildland boots can be significant.

Durability vs. Cost

NFPA-compliant boots are an investment. The high-quality materials, such as thick leather and melt-resistant soles, and the durable construction required to meet the standard mean these boots are significantly more expensive than non-compliant work boots. This initial cost, however, pays for longevity and safety.

Making the Right Choice for Your Goal

Your final selection should be guided by both the non-negotiable NFPA standards and your specific operational needs.

- If your primary focus is strict NFPA compliance: Verify the 8-inch height, all-leather upper, melt-resistant sole, and lace-up design before considering any other feature.

- If your primary focus is long-duration comfort on varied terrain: Look for a compliant boot in a "hiker" style with features like lower-profile heels for a more natural walking gait.

- If your primary focus is maximum ankle support and stability: A compliant boot in the traditional "logger" style will often provide a more rigid structure ideal for steep or unstable environments.

Choosing the right boot means ensuring it meets the safety standard first, then matching its specific design to the demands of your job.

Summary Table:

| NFPA 1977 Wildland Boot Requirement | Mandatory Specification |

|---|---|

| Height | Minimum 8 inches (from heel to top) |

| Upper Material | 100% Leather |

| Sole Material | Melt-resistant, Vibram-type lug sole |

| Closure | Lace-up design (no pull-on boots) |

| Threads | Inherently flame-resistant fibers |

Ensure your team is equipped with boots that meet and exceed NFPA 1977 standards. As a large-scale manufacturer, 3515 produces a comprehensive range of certified wildland fire boots for distributors, brand owners, and bulk clients. Our production capabilities ensure durable construction, all-leather uppers, and heat-resistant soles designed for maximum safety and comfort on the fireline. Contact our expert team today to discuss your specific needs and request a quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Lightweight Tactical Boots Custom Manufacturer for Desert & Combat Use

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What safety standards should oilfield work boots meet? Ensure OSHA & ASTM F2413 Compliance

- Why is waterproofing important in work boots? Protect Your Feet from Moisture, Injury, and Cold

- What are the key components to look for in durable, quality boots? Invest in Footwear Built to Last

- What are the characteristics of harness and engineer boots? Defining Two Iconic Rugged Styles

- What are some notable safety standards for oilfield boots? Your Guide to OSHA-Compliant Footwear

- Why is proper care and maintenance important for leather work boots? Extend Lifespan & Protect Your Investment

- What are packer boots and how do they differ from regular boots? Specialized Stability for Demanding Work

- Are water-resistant and water-repellent boots the same? A Guide to Choosing the Right Footwear