At its core, the durability and reliability of a chemical-resistant boot come from a multi-layered system of specialized materials. Each part of the boot—the outsole, the midsole, and the upper—is constructed with specific compounds chosen for their ability to withstand degradation from chemical exposure while maintaining structural integrity and protecting the wearer.

True reliability in safety footwear is not about a single feature. It's about a combination of purpose-built materials for chemical resistance, integrated protection against other workplace hazards, and the correct implementation of wider safety protocols.

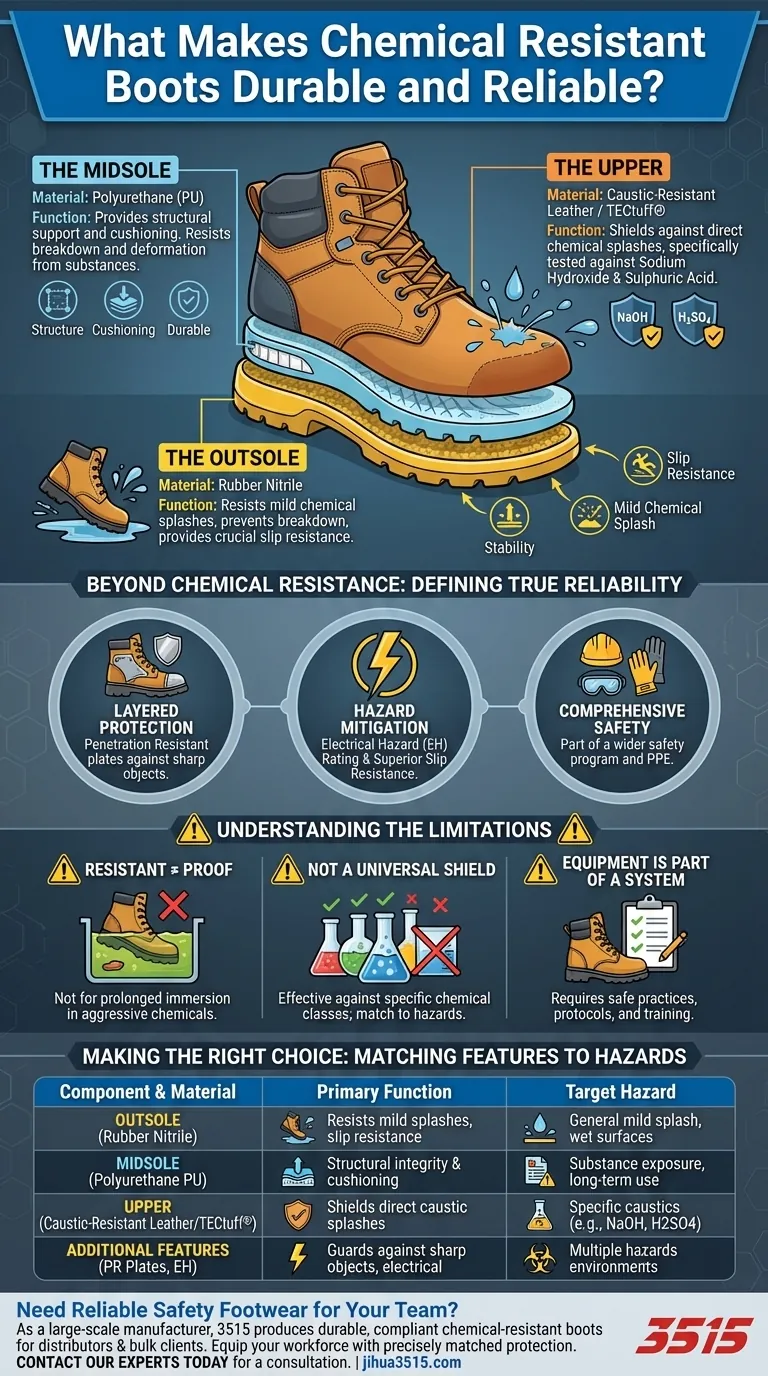

The Anatomy of a Chemical Resistant Boot

A boot's resilience is not determined by one "magic material" but by the strategic combination of components, each serving a distinct protective function.

The Outsole: Your First Line of Defense

The outsole is the part of the boot that makes direct contact with the ground. It is often made from rubber Nitrile.

This compound is specifically chosen for its stability when exposed to mild chemical splashes, preventing the material from breaking down, softening, or losing its protective qualities. It also provides crucial slip resistance on wet or contaminated surfaces.

The Midsole: Providing Structure and Support

Located between the outsole and your foot, the midsole provides cushioning and structural support. A Polyurethane (PU) midsole is a common choice in chemical-resistant boots.

PU is valued for its durability and resistance to breakdown from contact with various substances, ensuring the boot doesn't deform and compromise its protective structure.

The Upper: Shielding From Splashes and Spills

The upper portion of the boot faces the most direct threat from splashes. High-performance models use materials engineered and tested for this purpose.

This includes caustic-resistant leather, which has been specially treated and tested against harsh chemicals like Sodium Hydroxide and Sulphuric Acid. Other advanced materials like TECtuff® offer a synthetic alternative with similar tested resistance.

Beyond Chemical Resistance: Defining True Reliability

A truly reliable boot protects against the full spectrum of hazards present in a specific work environment. Chemical resistance is often just one piece of a larger safety puzzle.

Layering Protective Features

Manufacturers often integrate other critical safety features into the boot's design. This can include Penetration Resistant plates to guard against sharp objects on the ground.

Mitigating Electrical and Slip Hazards

Many chemical-resistant boots also carry an Electrical Hazard (EH) rating to protect against accidental contact with live electrical circuits.

Superior slip resistance is also paramount, as chemical spills inherently create slick, dangerous surfaces.

Understanding the Limitations

To use equipment safely, you must understand what it is—and is not—designed to do. Objectivity here is critical for safety.

"Resistant" Does Not Mean "Proof"

These boots are engineered to handle mild chemical splashes and intermittent contact. They are not designed for prolonged immersion in aggressive chemicals.

A Boot Is Not a Universal Shield

The materials mentioned, like Nitrile and specially treated leather, are effective against certain classes of chemicals but not all of them. Always match your boot's specifications to the specific chemical hazards you face.

Equipment Is Only Part of the System

A boot's effectiveness is directly tied to its role within a comprehensive safety program. The most durable boot cannot compensate for a lack of safe working practices.

This includes using all required personal protective equipment (PPE), adhering to strict safety protocols, and participating in regular hazard awareness training.

Making the Right Choice for Your Goal

Selecting the correct boot requires matching its specific features to the known hazards of your environment.

- If your primary focus is general protection from mild splashes: A boot with a Polyurethane midsole and a rubber Nitrile outsole provides a durable and reliable foundation.

- If you work with specific caustics like Sodium Hydroxide or Sulphuric Acid: Look for boots with uppers made from specifically tested, caustic-resistant leather or TECtuff®.

- If your workplace has multiple hazards: Prioritize boots that explicitly layer chemical resistance with other crucial ratings like Slip Resistance, EH, or Penetration Resistance.

Ultimately, an informed safety decision comes from understanding how your equipment is designed to protect you.

Summary Table:

| Component | Key Material | Primary Function |

|---|---|---|

| Outsole | Rubber Nitrile | Resists mild chemical splashes; provides slip resistance. |

| Midsole | Polyurethane (PU) | Maintains structural integrity and cushioning. |

| Upper | Caustic-Resistant Leather / TECtuff® | Shields against direct chemical splashes from specific hazards. |

| Additional Features | Penetration Resistant Plates, EH Rating | Protects against sharp objects and electrical hazards. |

Need reliable safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of chemical-resistant boots and work shoes, built with the specialized materials and layered protection detailed above.

We can help you equip your workforce with boots that are precisely matched to your specific chemical and safety hazards.

Contact our experts today for a consultation and to discuss your requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium KPU Injection Athletic Style Safety Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health