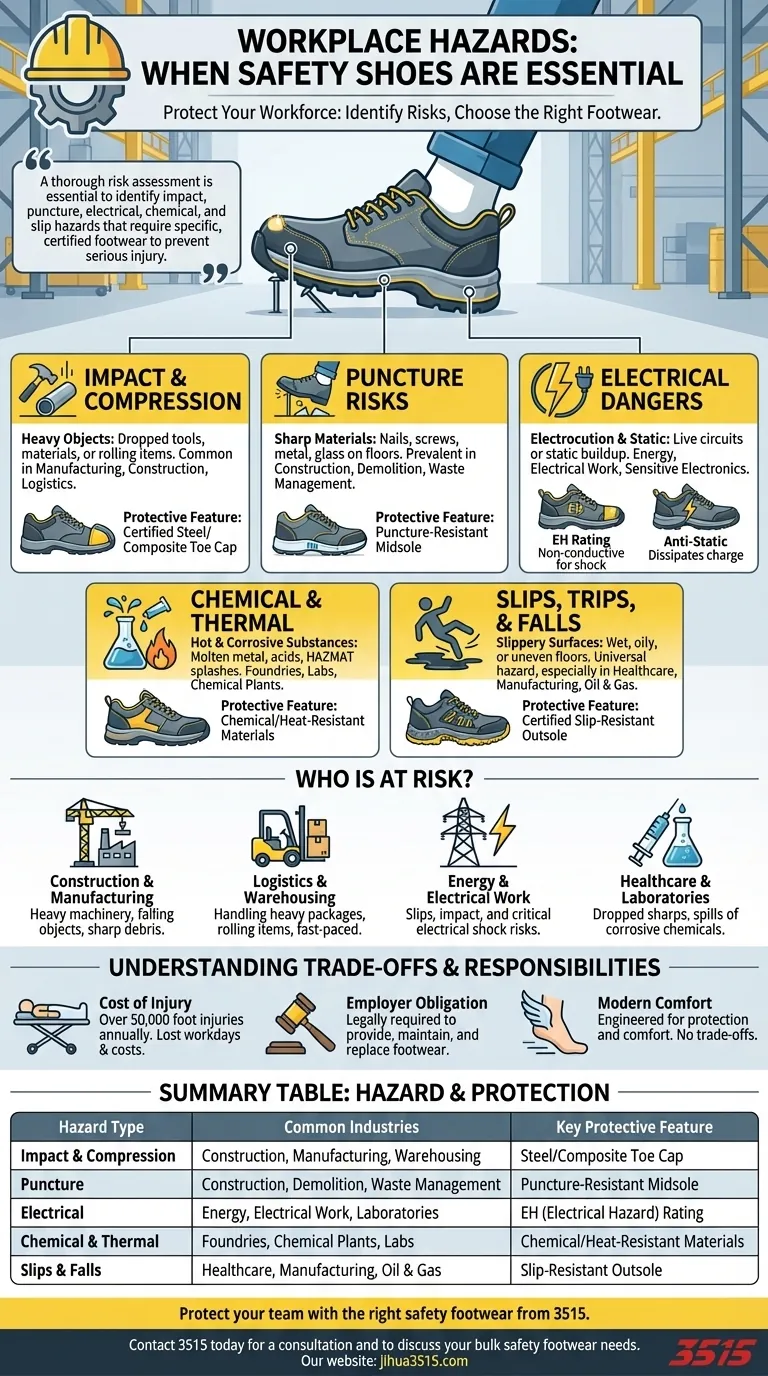

Workplace hazards indicating a need for safety shoes range from the obvious risk of falling objects to less apparent dangers like electrical currents, sharp materials, and slippery surfaces. You must provide protective footwear whenever a workplace assessment reveals risks of impact, compression, puncture, chemical or thermal exposure, and electrical contact.

The necessity for safety shoes extends far beyond construction sites. A thorough risk assessment is essential to identify not only impact and puncture dangers but also critical electrical, chemical, and slip hazards that require specific, certified footwear to prevent serious injury.

Identifying the Core Hazards to Your Feet

Understanding the specific dangers present in your work environment is the first step toward selecting the correct Personal Protective Equipment (PPE). Each type of hazard corresponds to a specific protective feature in safety footwear.

Impact and Compression from Heavy Objects

The most common reason for safety shoes is protection against heavy falling or rolling objects. This includes dropped tools, building materials, or items that can roll over the feet, such as pipes or wheels.

Work in manufacturing, construction, and logistics warehouses frequently involves these types of risks.

Puncture Risks from Sharp Materials

Floors can be littered with sharp objects like nails, screws, scrap metal, or broken glass. Standard footwear offers no protection against these items piercing the sole and causing severe foot injury.

This hazard is prevalent in construction, demolition, waste management, and even some manufacturing environments.

Electrical Dangers

Two distinct electrical hazards exist: electrocution and static discharge.

Non-conductive safety shoes are made with insulating materials that protect workers from shock when they might contact live electrical circuits.

Conversely, anti-static or conductive footwear is needed in environments where a buildup of static electricity could ignite flammable materials or damage sensitive electronics.

Chemical and Thermal Hazards

Feet can be exposed to splashes from hot or corrosive substances, such as molten metal, acids, or other hazardous materials (HAZMAT).

Specialized footwear is designed with materials that resist these substances, preventing burns and chemical-related injuries common in foundries, laboratories, and chemical plants.

Slips, Trips, and Falls

Slippery surfaces are a universal workplace hazard, from wet floors in healthcare to oily surfaces in manufacturing or oil and gas operations.

Safety shoes with certified slip-resistant outsoles provide critical traction and stability, significantly reducing the risk of falls that can lead to a wide range of injuries.

Who is at Risk? Key Industries and Roles

While often associated with construction, the need for safety shoes spans numerous sectors where foot injuries are a documented risk.

Construction and Manufacturing

These industries present a high concentration of hazards, including heavy machinery, falling objects, sharp debris, and potential for compression injuries.

Logistics and Warehousing

Workers constantly handle heavy packages that can be dropped. The fast-paced environment also increases the risk of items rolling over feet and navigating potentially slippery surfaces.

Energy and Electrical Work

Professionals in the oil and gas or electrical sectors face unique risks. They require protection from slips, impact, and, most critically, electrical shock.

Healthcare and Laboratories

While less obvious, these environments pose risks from dropped sharp instruments like scalpels or needles, as well as spills from potentially corrosive chemicals.

Understanding the Trade-offs and Responsibilities

Implementing a safety shoe policy is not just about avoiding injury; it's a legal and financial imperative. Ignoring these requirements carries significant consequences.

The Cost of Injury

Foot injuries are a significant cause of lost workdays. The National Safety Council reported over 50,000 foot-related injuries in a single year, leading to decreased productivity and substantial costs for employers.

Employer Obligation

Employers are legally required to provide, maintain, and replace necessary safety footwear at no cost to the employee. Failure to do so can result in sanctions from labor inspections.

The Myth of Discomfort

Modern safety shoes are engineered for both protection and comfort. Sacrificing safety for perceived comfort is a dangerous trade-off, as the right footwear can enhance productivity and well-being without compromising on certified protection.

Making the Right Choice for Your Environment

Your choice of safety shoe must be directly tied to the specific hazards identified in your workplace risk assessment.

- If your primary focus is protection from falling or rolling objects: You need footwear with certified impact and compression-resistant toe caps.

- If your primary focus is preventing electrical shock: Select shoes with an "EH" (Electrical Hazard) rating that are made from non-conductive materials.

- If your primary focus is avoiding slips and punctures: Prioritize boots with certified slip-resistant outsoles and puncture-resistant midsole plates.

- If your primary focus is handling hazardous materials: Choose footwear made from materials specifically designed to resist chemical or thermal splashes.

Investing in the correct safety footwear is a fundamental investment in your team's safety and your organization's operational health.

Summary Table:

| Hazard Type | Common Industries | Key Protective Feature |

|---|---|---|

| Impact & Compression | Construction, Manufacturing, Warehousing | Steel/Composite Toe Cap |

| Puncture | Construction, Demolition, Waste Management | Puncture-Resistant Midsole |

| Electrical | Energy, Electrical Work, Laboratories | EH (Electrical Hazard) Rating |

| Chemical & Thermal | Foundries, Chemical Plants, Labs | Chemical/Heat-Resistant Materials |

| Slips & Falls | Healthcare, Manufacturing, Oil & Gas | Slip-Resistant Outsole |

Protect your team with the right safety footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear designed to mitigate the specific hazards your workforce faces—from impact and puncture to electrical and slip risks.

Investing in high-quality, comfortable safety footwear is an investment in your team's well-being and your operation's productivity. Let us help you equip your workforce with the right protection.

Contact 3515 today for a consultation and to discuss your bulk safety footwear needs.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Are there unisex oil resistant safety boots? Find the Perfect Fit for Your Team

- What are some extra features that can be found in safety shoes? Beyond Basic Steel Toe Protection

- What role do slip-resistant rubber materials play in safety shoes? Ensuring Grip and Stability in Hazardous Workplaces

- How do professional-grade safety shoes reduce injury severity? Mitigate Risks in Construction & Manufacturing

- What is the purpose of using a standardized 30x21x21cm load box in labor tests? Optimize Safety with Data.

- What is the difference between work boots and safety boots? Certified Protection vs. General Durability

- How does footwear design contribute to reducing OHS risks on fishing vessels? Essential Marine Safety Strategies

- What tips can help ensure safety toe boots fit correctly? Achieve Optimal Protection & Comfort