To ensure safety toe boots fit correctly, you must measure your feet professionally, try them on at the end of the day when your feet are at their largest, and wear the same socks you use for work. The boot should feel snug around the heel and midfoot, with enough room to wiggle your toes freely inside the protective cap.

A proper fit for safety footwear is not a matter of comfort, but a non-negotiable component of its protective function. A boot that doesn't fit correctly can create new hazards, negating the very reason you wear it.

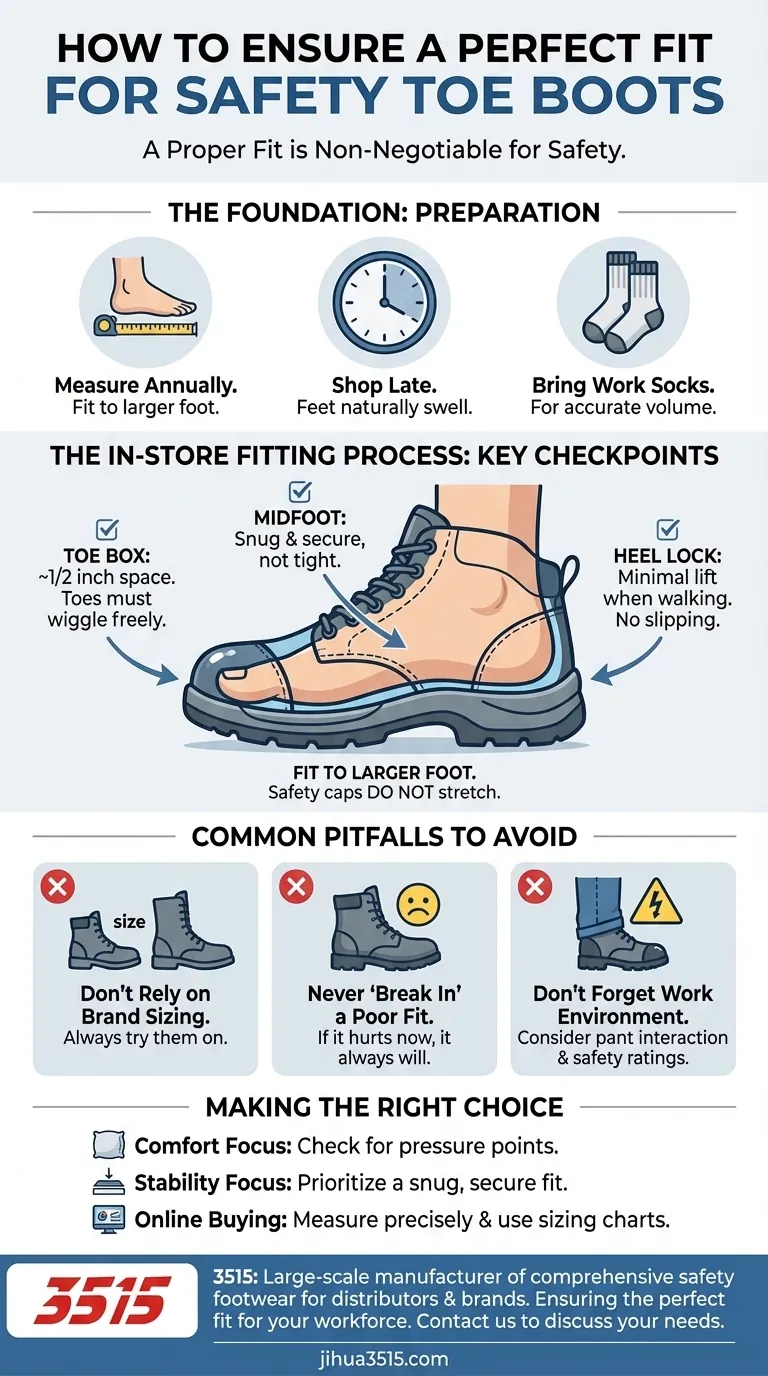

The Foundation: Preparing for a Proper Fit

Before you even step into a store, a few preparatory steps can make the difference between a perfect fit and a painful mistake. Your feet change over time, and accounting for this is the first step.

Measure Your Feet Annually

Your foot size and shape can change over the years. It's critical to have both feet professionally measured at least once a year, as most people have one foot that is slightly larger than the other.

Shop at the Right Time

Schedule your boot shopping for the afternoon or evening. Your feet naturally swell throughout the day, and trying on boots when they are at their largest ensures a comfortable fit when you're deep into a workday.

Bring Your Work Socks

The thickness of your socks has a significant impact on how a boot fits. Always bring the specific type of socks you wear on the job to get a true and accurate assessment of the boot's size and volume.

The In-Store Fitting Process: Key Checkpoints

Once you are trying on boots, you need to assess several key areas. Never rush this process; a few minutes of careful evaluation will save you weeks of discomfort.

Fit to Your Larger Foot

Always fit the boot to your larger foot. It is far easier to add a small insole to tighten a slightly loose boot than it is to endure the pain of a boot that is too small.

The "Snug, Not Tight" Rule

The boot should feel snug and secure around your heel and the top of your foot (the instep). However, it should not feel tight, pinched, or constricted in any area.

Assess the Toe Box

The defining feature of a safety boot is the protective toe cap. Unlike leather, this cap will not stretch or break in. You must have about a half-inch of space between your longest toe and the end of the boot, and you should be able to wiggle your toes freely.

Test for Heel Lock

Walk around in the boots for several minutes. Pay close attention to your heel. A small amount of movement is normal, but if your heel is noticeably lifting out of the heel cup with each step, the fit is too loose and will cause blisters and instability.

Common Pitfalls to Avoid

Even with the right knowledge, common misconceptions can lead to a poor purchasing decision. Being aware of these pitfalls is crucial for long-term safety and comfort.

Don't Rely on Brand Sizing

Boot sizes are not standardized across manufacturers. A size 10 in one brand may fit completely differently from a size 10 in another. Always try on the specific boot you intend to buy.

Never "Break In" a Poor Fit

While a quality leather boot will soften and conform to your foot over time, you should never purchase a boot that is uncomfortable from the start. A boot that feels too short or narrow will always be too short or narrow.

Forgetting Your Work Environment

Consider how your work pants or coveralls will interact with the boot. Ensure the leg openings fit comfortably over the boot without creating a tripping hazard. Also, confirm the boot's safety rating (e.g., EH for electrical hazards) matches your workplace requirements.

Making the Right Choice for Your Job

Your final decision should be guided by your specific needs and daily tasks.

- If your primary focus is all-day comfort: Pay closest attention to the heel lock and ensure there are no pressure points across the top of your foot, especially when kneeling.

- If your primary focus is stability and safety: Prioritize a snug fit that prevents your foot from sliding inside the boot during dynamic movements, ensuring your toes remain protected behind the safety cap.

- If you are buying online: Measure your feet precisely and compare your measurements to the manufacturer's specific sizing chart, and read reviews to see if the boots tend to run large or small.

Ultimately, the right safety boot becomes an extension of your body, providing protection without calling attention to itself.

Summary Table:

| Key Fitting Checkpoint | What to Look For |

|---|---|

| Foot Measurement | Measure both feet annually; fit to the larger foot. |

| Trying-On Time | Shop in the afternoon/evening when feet are naturally swollen. |

| Toe Box Fit | Must have ~1/2 inch of space; toes should wiggle freely. |

| Heel & Midfoot | Should feel snug and secure, not tight or constricting. |

| Heel Lock | Minimal heel lift when walking to prevent blisters. |

Ready to source perfectly fitting safety boots for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring a perfect fit is achievable for your entire workforce or product line.

Contact 3515 today to discuss your safety footwear needs and experience the difference of working with a dedicated manufacturer.

Visual Guide

Related Products

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are safety shoes also known as? A Guide to Protective Footwear Terms

- What factors contribute to the comfort and durability of safety boots? A Guide to All-Day Protection

- What additional features do S5 safety boots have compared to S4? Enhanced Puncture & Slip Resistance for Hazardous Sites

- What does electrical hazard protection (EH) in safety footwear entail? Essential Safety for High-Risk Environments

- How does the ergonomic design of protective footwear reduce the risk of WMSD? Enhance Worker Safety and Comfort

- Which industries commonly require safety shoes? A Guide to Workplace Foot Protection

- Why is it necessary for safety boots designed for livestock environments to possess moisture-resistant properties?

- Why should workers avoid everyday shoes in high-risk work situations? Ensure Proper Foot Protection