Yes, unisex oil-resistant safety boots exist and are widely available. However, the term "unisex" refers to the boot's design and features, not a universal fit. The primary challenge is sizing, as men's and women's feet have anatomical differences, meaning a direct size-for-size match is rarely effective.

While the boot's protective qualities are gender-neutral, its fit is not. The key to successfully using unisex safety boots is to ignore the "unisex" label for sizing and instead focus on finding the correct fit for the individual wearer's foot, which often requires a size conversion.

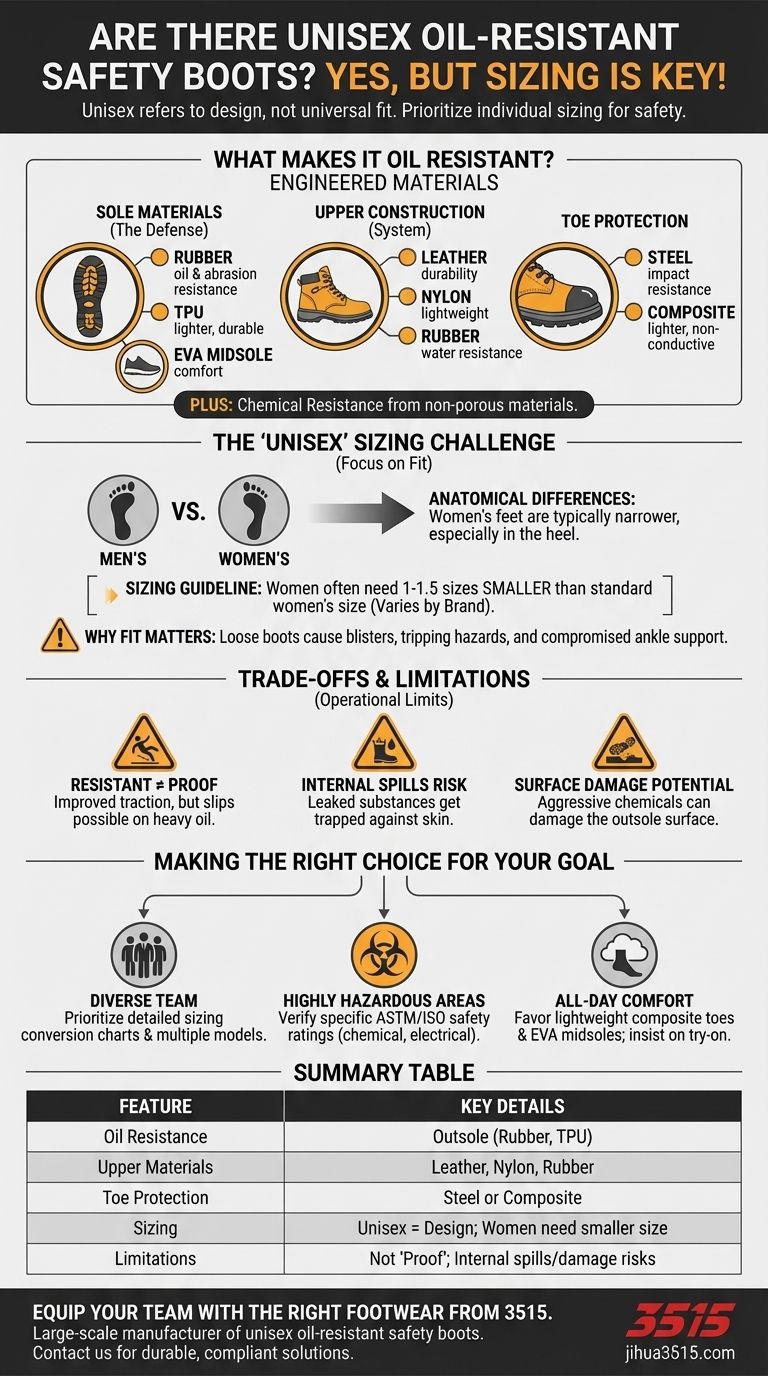

What Makes a Safety Boot 'Oil Resistant'?

Understanding the technology behind oil resistance helps in selecting the right boot. The protection isn't just a surface coating; it's engineered into the core materials of the boot itself.

The Role of Sole Materials

The outsole is the first line of defense. Specific materials are chosen for their ability to resist degradation when exposed to petrochemicals.

The most common oil-resistant materials are rubber, which offers excellent oil and abrasion resistance, and thermo-polyurethane (TPU), which is lighter than rubber but still highly durable. Some boots use ethylene-vinyl acetate (EVA) in the midsole for comfort and stability.

Upper and Toe Construction

The entire boot must work as a system. The upper materials and toe protection are just as critical as the sole.

Uppers are typically made from leather for its durability and breathability, nylon for a lightweight alternative, or rubber for maximum water resistance. Toe protection is usually either steel for maximum impact resistance or composite materials, which are lighter and don't conduct electricity or temperature.

Beyond Oil: Chemical Resistance

Most oil-resistant boots also offer a degree of chemical resistance. The same durable, non-porous materials that repel oil can protect against spills from various industrial chemicals, safeguarding the wearer's skin.

The Challenge of "Unisex" Sizing

The most common point of failure when purchasing unisex boots is an improper fit. This is not just a comfort issue; it is a significant safety hazard.

Anatomical Differences

Men's and women's feet differ in more than just length. Women's feet are typically narrower, particularly in the heel, relative to the ball of the foot. A boot designed on a standard men's "last" (the foot-shaped model) may feel loose and unsupportive for a female wearer.

A General Sizing Guideline

A common rule of thumb is for women to select a unisex boot that is 1 to 1.5 sizes smaller than their standard women's shoe size. However, this is only a starting point and varies by brand.

Why a Proper Fit is Non-Negotiable

A poorly fitting boot can cause blisters and discomfort, leading to distraction. More critically, it can create a tripping hazard if the foot slides inside the boot, and it compromises ankle support, increasing the risk of injury.

Understanding the Trade-offs and Limitations

Even the highest-quality safety boots have operational limits. Being aware of these ensures you maintain realistic expectations for safety.

"Resistant" Does Not Mean "Proof"

An oil-resistant, anti-slip sole significantly improves traction but cannot guarantee against slips in all conditions, especially on surfaces with heavy, continuous oil contamination.

The Risk of Internal Spills

The boot's protection is external. If oil or chemicals leak into the top of the boot, the materials can trap the substance against the skin, negating the protective benefits.

Potential for Surface Damage

While the boot is designed to resist oil, some aggressive solvents or chemicals can still cause permanent damage to the outsole's surface, potentially reducing its non-slip effectiveness over time.

Making the Right Choice for Your Goal

Selecting the correct boot depends entirely on your specific needs and environment. Use these guidelines to filter your options.

- If your primary focus is sourcing for a diverse team: Prioritize brands that offer detailed sizing conversion charts and consider providing a few different models to accommodate various foot shapes.

- If your primary focus is safety in highly hazardous areas: Look beyond "oil-resistant" and verify specific ASTM or ISO safety ratings for chemical resistance, toe protection, and electrical hazards.

- If your primary focus is all-day comfort for long shifts: Favor boots with lightweight composite toes and EVA midsoles, but insist on a try-on period to ensure a perfect fit without pressure points.

Ultimately, choosing the right unisex safety boot comes down to prioritizing the individual's fit and the specific hazards of their environment.

Summary Table:

| Feature | Key Details |

|---|---|

| Oil Resistance | Primarily in the outsole; common materials: rubber, TPU. |

| Upper Materials | Leather, nylon, or rubber for durability and protection. |

| Toe Protection | Steel (heavy-duty) or composite (lightweight, non-conductive). |

| Sizing Challenge | 'Unisex' refers to design, not fit; women typically need 1-1.5 sizes smaller. |

| Limitations | 'Resistant' ≠ 'Proof'; internal spills and surface damage are risks. |

Equip your team with the right safety footwear from 3515.

As a large-scale manufacturer, we produce a comprehensive range of unisex oil-resistant safety boots for distributors, brand owners, and bulk clients. Our expertise ensures your team gets durable, compliant footwear with a perfect fit, enhancing safety and comfort.

Contact us today for a customized solution that meets your specific needs.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are the differences between internal and external metatarsal guards? Choose the Right Protection for Your Job

- Why is fit and comfort important in protective footwear? Prevent Injuries & Boost Productivity

- Is ANSI Z41 still valid for safety footwear? No, It's Replaced by ASTM F2413

- How do the soles of firefighter boots perform under heat? Engineered for Melt-Resistant Safety

- What are the changes to puncture resistance in the new EN ISO 20345 standard? Understand P, PL, and PS Markings

- Why is prioritizing high-quality safety shoes a strategic investment for sustainability? Scale Your Business with 3515

- What is the recommended method for cleaning textile or synthetic work shoes? A Gentle Guide to Preserve Your Footwear

- Why is stabilization control essential for UHSS safety shoe toe caps? Key Factors for High-Strength Protection