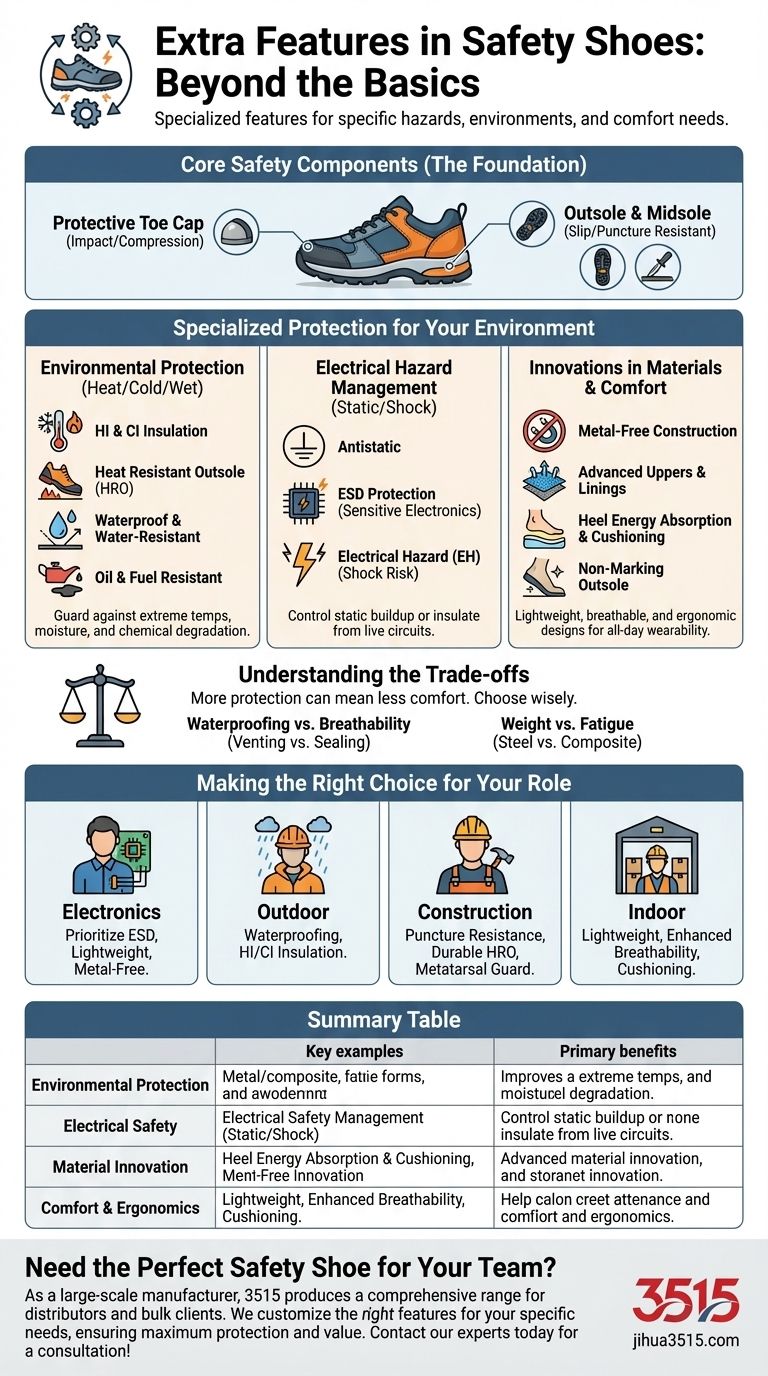

Beyond the basic steel toe cap, modern safety shoes incorporate a vast array of specialized features designed for specific hazards, environments, and comfort needs. These extras range from environmental protections like heat and cold insulation to advanced material properties such as metal-free construction, electrostatic discharge (ESD) protection, and enhanced breathability through linings like Coolmax.

The most effective safety footwear isn't the one with the most features, but the one with the right features. Understanding these additions is crucial for matching the shoe precisely to the hazards and demands of your specific work environment.

Beyond the Basics: Core Safety Components

Before exploring extra features, it's essential to understand the foundation. Every safety shoe is built around a few non-negotiable protective elements.

The Protective Toe Cap

The most recognized feature of a safety shoe is its reinforced toe cap, designed to protect against impact and compression. While steel is the traditional material, composite (made from materials like carbon fiber, plastic, or Kevlar) is a popular modern alternative that is lighter and does not conduct electricity.

The Outsole and Midsole

The outsole is the direct contact point with the ground, engineered for properties like slip, oil, and fuel resistance. A puncture-resistant midsole, often made of steel or flexible composite fabric, is inserted between the insole and outsole to protect against sharp objects piercing the bottom of the foot.

Specialized Protection for Your Environment

Many extra features are designed to counter specific environmental risks beyond simple impact. Selecting the right ones is critical for both safety and comfort.

Managing Temperature Extremes

For those working in extreme temperatures, thermal regulation is key. Heat Insulation (HI) and Cold Insulation (CI) protect your feet from the ambient environment. For direct contact with hot surfaces, a Heat Resistant Outsole (HRO) is required, typically able to withstand temperatures of 300°C for one minute.

Resisting Moisture and Chemicals

A waterproof shoe, often featuring a membrane like GORE-TEX, keeps feet dry from external sources. This is a step beyond a water-resistant upper, which only offers protection against light moisture. For mechanics or industrial workers, an oil and fuel resistant outsole is essential to prevent material degradation and maintain traction.

Navigating Electrical Hazards

This is a critical area where specifics matter. Antistatic shoes reduce the buildup of static electricity, dissipating it to the ground to prevent uncontrolled sparks. Electrostatic Discharge (ESD) footwear offers a lower and more tightly controlled range of electrical resistance, essential for protecting sensitive electronic components. Conversely, Electrical Hazard (EH) rated shoes are designed to insulate the wearer from the ground, reducing the risk of electric shock from live circuits.

Innovations in Materials and Comfort

Modern advancements focus on reducing weight and increasing comfort without compromising safety standards.

The Rise of Metal-Free Footwear

Using composite toe caps and puncture plates creates a metal-free shoe. These are significantly lighter than their steel counterparts, reducing fatigue, and are ideal for workers who must pass through metal detectors frequently.

Advanced Upper and Lining Materials

Modern uppers are not just leather. They can be made from advanced textiles that offer enhanced breathability or high cut resistance. Inside the shoe, linings like Coolmax wick moisture away to keep feet dry, while warm linings provide thermal comfort in cold conditions.

Features for All-Day Wearability

Heel energy absorption and soft impact foam insoles reduce the strain from walking on hard surfaces all day. A non-marking outsole prevents leaving scuff marks on finished floors, a crucial feature for many indoor trades.

Understanding the Trade-offs

Adding features often involves balancing competing priorities. More protection can sometimes mean less comfort or flexibility if not chosen carefully.

The Myth of "One-Size-Fits-All"

A shoe with maximum heat resistance and a metatarsal guard will be heavier and stiffer than one designed for a warehouse floor. Over-specifying features for your role can lead to unnecessary fatigue.

Waterproofing vs. Breathability

A fully waterproof membrane is excellent at keeping water out, but it can limit the shoe's ability to vent sweat and heat. For hot environments, prioritizing a highly breathable upper may be more important for all-day comfort than total waterproofing.

Weight and Fatigue

The choice between steel and composite components is a primary example of this trade-off. While both meet safety standards, the lighter weight of composite materials can make a significant difference in perceived energy levels at the end of a long shift.

Making the Right Choice for Your Role

To select the right features, start by analyzing your daily tasks and the most significant risks you face.

- If your primary focus is working with sensitive electronics: Prioritize ESD protection and consider the benefits of a lightweight, metal-free design.

- If your primary focus is outdoor work in variable weather: Waterproofing is non-negotiable, and you should consider either Cold (CI) or Heat (HI) insulation based on your climate.

- If your primary focus is construction or heavy industry: Puncture resistance, metatarsal guards, and a durable, heat-resistant outsole are your most critical features.

- If your primary focus is standing for long shifts indoors: Lightweight design, enhanced breathability, and superior cushioning from heel energy absorption will provide the most benefit.

Choosing the right safety footwear is a direct investment in your daily performance, comfort, and long-term well-being.

Summary Table:

| Feature Category | Key Examples | Primary Benefit |

|---|---|---|

| Environmental Protection | Heat/Cold Insulation, Waterproofing | Protects against extreme temperatures and moisture |

| Electrical Safety | ESD, Antistatic, Electrical Hazard (EH) | Manages electrical risks for wearer and equipment |

| Material Innovation | Metal-Free Composite, Cut-Resistant Uppers | Reduces weight and fatigue, enhances protection |

| Comfort & Ergonomics | Breathable Linings, Heel Energy Absorption | Improves all-day wearability and reduces strain |

Need the Perfect Safety Shoe for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, from ESD-protective models for electronics to insulated, waterproof boots for outdoor work.

We can help you select or customize the ideal safety footwear with the right features for your specific hazards and environment, ensuring maximum protection, comfort, and value.

Contact our experts today for a consultation and get a quote tailored to your needs!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What is the purpose of using a shoe spray on work shoes and socks? Enhance Hygiene and Safety

- What is the purpose of the midsection with insert for ladder support in safety footwear? Enhance Stability & Safety

- What is the safety toe cap and what materials is it made from? Choose Steel or Composite for Your Job

- What is the necessity of using a digital surface roughness tester for floor characterization? Precision Safety Data

- What makes safety shoes non-slip? The Engineered System for Superior Traction

- Why might healthcare professionals need safety shoes? Essential Protection for Hospital Hazards

- What is the clinical preventive significance of professional protective footwear for APS? Lower Necrosis Risks Now

- What are the characteristics of composite toe protection in work boots? Lightweight & Non-Conductive Safety