Protective footwear is required in any work environment where employees are exposed to a risk of foot injury. This includes dangers from rolling or falling objects, sharp materials that could puncture the sole, contact with hot or corrosive substances, and electrical hazards.

The core principle is not about a specific job title but about the specific hazards present in the work environment. A formal hazard assessment is the definitive way to determine the need for protective footwear and to select the correct type for the risks involved.

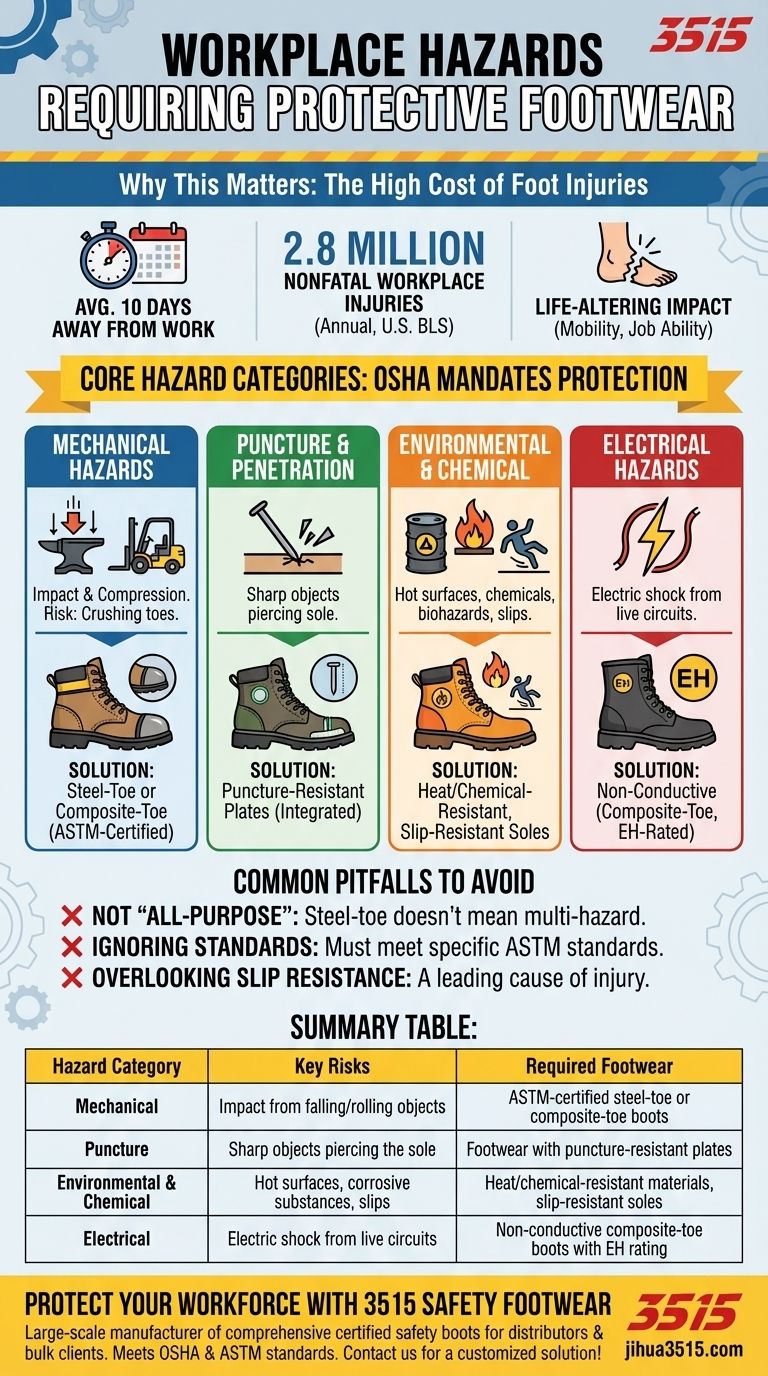

Why This Matters: The High Cost of Foot Injuries

Failing to use proper protective footwear is not a minor oversight; it exposes workers to some of the most common and debilitating workplace injuries. Understanding the data reveals the true scope of the risk.

The Data Doesn't Lie

According to the U.S. Bureau of Labor Statistics, there were 2.8 million nonfatal workplace injuries in a recent year, with the average injury resulting in 10 days away from work.

The National Safety Council reports that contact with objects and equipment, along with falls, slips, and trips, are among the leading causes of preventable workplace injuries and deaths. Protective footwear is a primary defense against these exact risks.

It's More Than Just a Foot

A serious foot injury can be life-altering, impacting a worker's mobility, ability to perform their job, and overall quality of life long after the incident. Proper PPE is a simple, effective measure to prevent this.

Core Hazard Categories Requiring Protection

OSHA mandates protective footwear when specific dangers are present. These risks can be broken down into several key categories.

Mechanical Hazards: Impact and Compression

This is the most commonly recognized hazard. It involves the risk of something heavy falling on or rolling over the foot.

Safety-toe boots, often steel-toe or composite-toe, are designed to withstand significant force, protecting the toes from being crushed. This is essential in warehouses with forklifts, on loading docks, and in any environment where heavy materials are moved.

Puncture and Penetration Hazards

This category covers risks from sharp objects that could pierce the sole of a standard shoe, such as nails at a construction site, sharp metal scraps in a machine shop, or even dropped knives in a professional kitchen.

Footwear with puncture-resistant plates integrated into the midsole is required to protect against these specific dangers.

Environmental and Chemical Hazards

Work environments can expose feet to a range of other dangers, including extreme temperatures, moisture, and dangerous substances.

This includes protection from hot surfaces (like in welding or paving), corrosive chemicals, poisonous materials, and biohazards. It also includes preventing injuries from slips on wet or oily surfaces, a leading cause of accidents.

Electrical Hazards

For electricians and others working near live circuits, footwear must provide insulation from the ground to prevent electric shock.

Composite-toe boots are often used as they are non-conductive, unlike steel. Look for footwear specifically rated for Electrical Hazard (EH) protection, which meets established ASTM standards.

Common Pitfalls to Avoid

Simply mandating "safety shoes" is not enough. Choosing the wrong type of protection can create a false sense of security and leave employees vulnerable.

Mistaking "Steel-Toe" for "All-Purpose"

A steel-toe boot only protects against impact and compression. It offers no inherent protection against punctures, chemicals, or electrical hazards unless it is specifically designed and certified for those risks as well.

Ignoring Certification Standards

OSHA requires that all protective footwear meet standards set by ASTM International (formerly the American Society for Testing and Materials). A compliant boot will be marked with the specific standard it meets (e.g., ASTM F2413-18), indicating precisely which hazards it has been tested to resist.

Overlooking Slip Resistance

Falls, slips, and trips are a top cause of injury across almost every industry. Even in an environment without impact or puncture risks, a wet or oily floor presents a significant hazard that requires footwear with appropriate slip-resistant soles.

Making the Right Choice for Your Goal

The right footwear depends entirely on a clear-eyed assessment of the specific hazards in your environment.

- If your primary environment is a warehouse or factory: Prioritize footwear with certified impact and compression resistance to protect against rolling equipment and falling items.

- If your primary environment is a construction or renovation site: You need multi-hazard protection, including impact resistance, puncture-proof soles, and highly slip-resistant treads.

- If your primary environment involves electrical work: Select non-conductive footwear specifically rated for Electrical Hazard (EH) protection to prevent shock.

- If your primary environment is a commercial kitchen or is consistently wet: Emphasize highly slip-resistant soles and materials that can protect against hot liquids or sharp tools.

Ultimately, a thorough hazard assessment is the first and most critical step in creating a safe work environment from the ground up.

Summary Table:

| Hazard Category | Key Risks | Required Footwear Protection |

|---|---|---|

| Mechanical Hazards | Impact from falling/rolling objects | ASTM-certified steel-toe or composite-toe boots |

| Puncture Hazards | Sharp objects piercing the sole | Footwear with puncture-resistant plates in the midsole |

| Environmental & Chemical Hazards | Hot surfaces, corrosive substances, slips | Heat/chemical-resistant materials, slip-resistant soles |

| Electrical Hazards | Electric shock from live circuits | Non-conductive composite-toe boots with EH rating |

Protect your workforce with the right safety footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear designed to meet OSHA and ASTM standards for impact, puncture, electrical, and chemical hazards. Ensure your team's safety and compliance — contact us today for a customized solution tailored to your specific workplace risks!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- What benefits do safety shoes provide in harsh weather conditions? Ensure Worker Safety and Productivity

- What makes safety footwear durable and long-lasting? Key Materials & Construction Methods

- What is the role of OSHA in relation to safety footwear? Ensure Full Compliance for Your Workforce

- Why is moisture management a critical design feature for safety boots? Boost Mining Safety and Worker Skin Health.

- Which sole material has excellent performance in chemical resistance? Choose the Right Protection for Your Worksite

- Where are composite-toe boots considered essential? For High-Risk Work Zones Requiring Certified Safety

- What role do wearable IMUs play in optimizing protective equipment? Data-Driven Safety for Heavy Labor

- What are the advantages of rubber outsoles in work shoes? Superior Grip, Durability & Safety