At its core, durable safety footwear is the product of superior materials, robust construction methods, and intelligent design. It's not just one feature, but a complete system where high-quality leather, reinforced stitching, and a well-engineered sole work together to withstand daily wear and tear in demanding environments.

The true hallmark of long-lasting safety footwear isn't just its ability to resist damage, but its very construction. Durability is a function of the quality of its individual parts and, most critically, the method used to join them together.

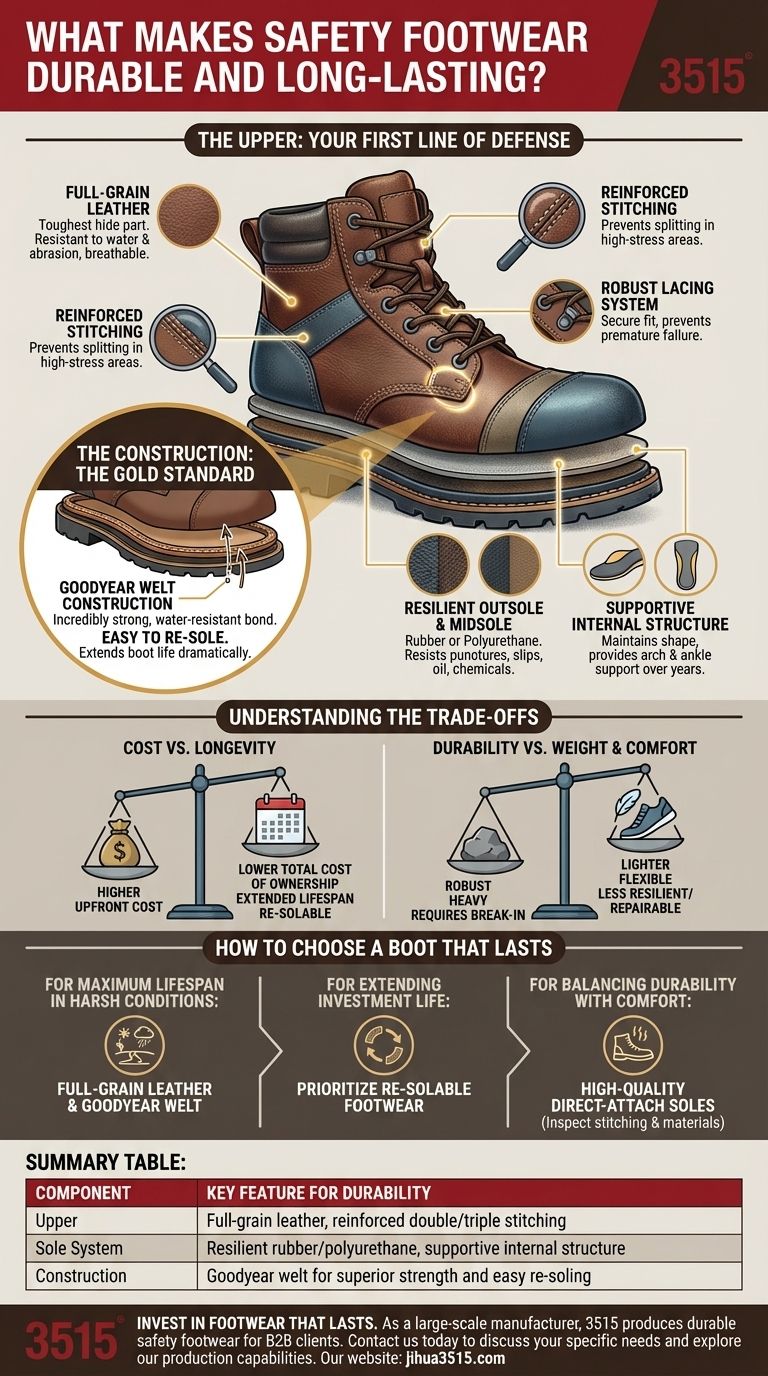

The Anatomy of a Durable Boot

To understand what makes footwear last, we need to look at its core components: the upper section that protects your foot, and the sole system that grounds you.

The Upper: Your First Line of Defense

The upper is everything above the sole. Its durability is determined by the primary material and how it's assembled.

High-quality footwear almost always begins with full-grain leather. This is the toughest part of the hide, offering excellent resistance to water and abrasion while remaining breathable.

The integrity of the upper also depends on reinforced stitching. Double or triple-stitched seams, especially in high-stress areas, prevent the boot from splitting or coming apart under strain.

Finally, a robust lacing system with sturdy eyelets and durable laces ensures a secure fit over the boot's entire lifespan, preventing the premature failure that can occur with cheaper components.

The Foundation: The Sole System

The sole is the workhorse of any boot, and its construction is critical for longevity. It consists of the outsole (what touches the ground) and the midsole (for support and shock absorption).

A durable sole is made from a resilient material like rubber or polyurethane that resists punctures, slips, and degradation from chemicals or oil.

The internal structure, including the insole and shank, provides critical arch and ankle support. In a durable boot, these components are designed to maintain their shape and supportive qualities over years of use, not compress and fail within months.

The Construction: How It's All Held Together

The method used to attach the upper to the sole is arguably the most important factor in a boot's lifespan and repairability.

The gold standard for durable footwear is the Goodyear welt construction. This involves stitching a strip of leather (the welt) to both the upper and the sole.

This method creates an incredibly strong, water-resistant bond. Most importantly, it allows a cobbler to easily remove and replace the entire sole without damaging the upper, dramatically extending the boot's life.

Understanding the Trade-offs

Choosing the most durable footwear isn't always a simple decision. It involves balancing competing factors.

Cost vs. Longevity

The most durable boots, particularly those with Goodyear welt construction and full-grain leather, have a higher upfront cost.

However, their extended lifespan and the ability to replace the sole often result in a much lower total cost of ownership compared to buying cheaper, disposable boots repeatedly.

Durability vs. Weight and Comfort

Robust materials and construction methods add weight. The toughest boots can feel stiff and heavy initially, often requiring a "break-in" period.

Less durable, direct-attached or cemented boots are often lighter and more flexible out of the box, but they sacrifice the long-term resilience and repairability of their heavier counterparts.

How to Choose a Boot That Lasts

Focus on your primary goal to select footwear that meets your specific durability needs.

- If your primary focus is maximum lifespan in harsh conditions: Seek out boots made from full-grain leather with a Goodyear welt construction.

- If your primary focus is extending the life of your investment: Prioritize footwear that is specifically built to be re-soled, which is the most common point of failure.

- If your primary focus is balancing durability with immediate comfort: Look for high-quality boots with direct-attach soles, but inspect the stitching and material quality closely.

Ultimately, choosing durable safety footwear is an investment in both your long-term safety and your budget.

Summary Table:

| Component | Key Feature for Durability |

|---|---|

| Upper | Full-grain leather, reinforced double/triple stitching |

| Sole System | Resilient rubber/polyurethane, supportive internal structure |

| Construction | Goodyear welt for superior strength and easy re-soling |

Invest in footwear that lasts. As a large-scale manufacturer, 3515 produces a comprehensive range of durable safety footwear for distributors, brand owners, and bulk clients. Our expertise in robust construction methods ensures your investment delivers long-term value and protection. Contact us today to discuss your specific needs and explore our production capabilities.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What is the purpose of safety footwear in the workplace? Essential Protection for Your Workforce

- How do high-performance protective footwear help prevent diabetic foot ulcers? Expert Biomechanical Insights

- What core safety benefits do industrial-grade safety shoes provide for mining? Protect Your Team from High-Intensity Risks

- What primary function does specialized safety footwear serve in a CSSD? Expert Guide to Biological Barriers

- How does OSHA enforce compliance for safety shoes? A Guide to Avoiding Citations

- What is the significance of scientific heel height design in protective footwear for maintaining foot health?

- What specific mechanical protections do industrial safety shoes provide in cable factories? Expert Guide for Max Safety

- Why is the sealing and fit of PPE critical to the safety of quarry workers? Ensure Maximum Workplace Protection