Composite-toe boots are essential safety equipment in high-risk work environments where feet are exposed to impact, compression, or electrical hazards. They are mandated in sectors like construction, heavy industry, and manufacturing to comply with occupational health and safety standards.

The core reason composite-toe boots are essential is that they provide certified impact protection using non-metallic materials. This makes them the definitive choice for environments with electrical hazards and a superior option for workers looking to minimize fatigue over long shifts.

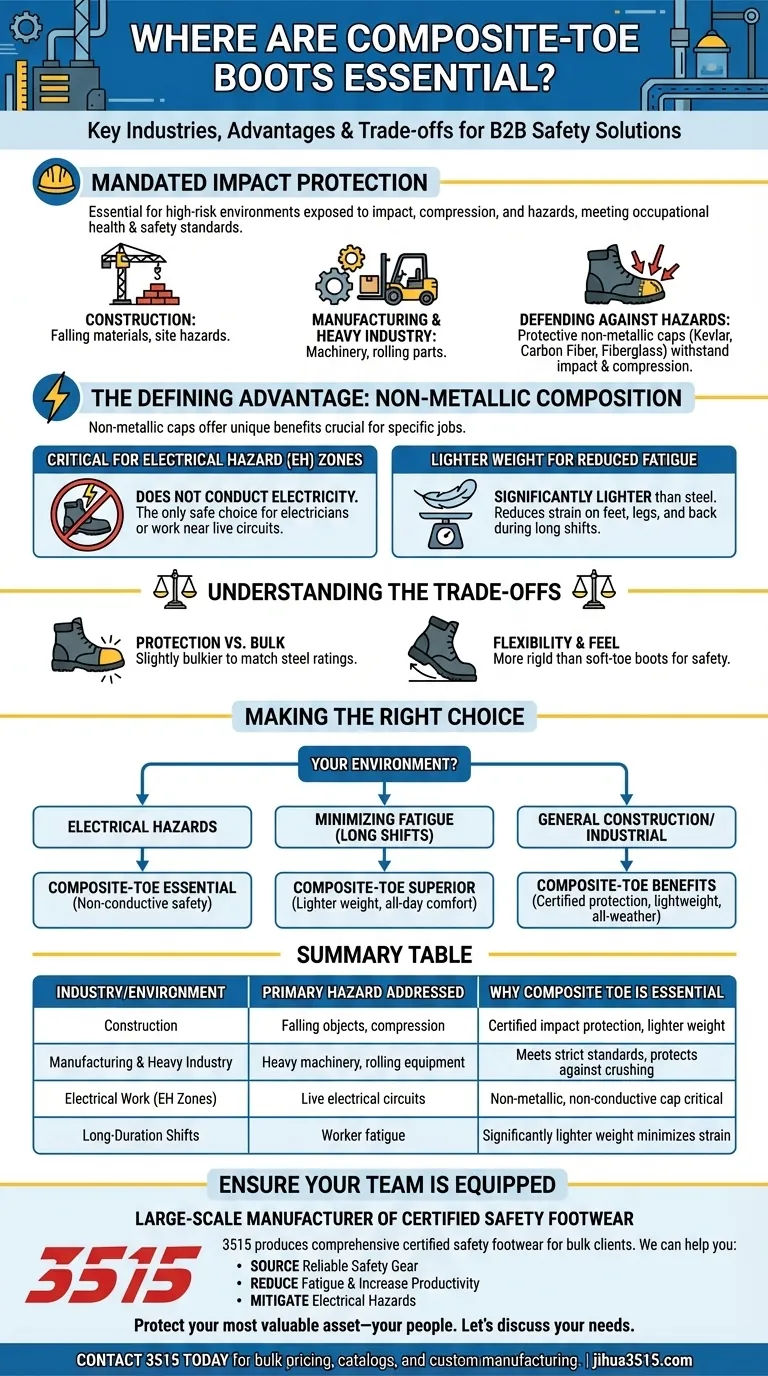

The Core Function: Mandated Impact Protection

Any safety boot's primary job is to protect your feet from injury. Composite-toe boots are engineered to meet strict industry standards for this purpose.

Meeting Occupational Safety Standards

Workplace safety is not optional. Regulatory bodies mandate specific levels of protection for footwear in hazardous environments. Composite-toe boots are designed and tested to meet these standards, providing reliable defense against common workplace dangers.

Key Industries Requiring Protection

These boots are a requirement in any field where foot injuries are a significant risk. This includes construction sites, where falling materials are common, and manufacturing or heavy industrial settings, where heavy machinery and parts are handled constantly.

Defending Against Common Hazards

The protective toe cap, made from materials like Kevlar, carbon fiber, or fiberglass, is designed to withstand significant impacts from falling objects and compression from heavy rolling equipment, preventing severe foot injuries.

The Defining Advantage: Non-Metallic Composition

While steel-toe boots also provide impact protection, the non-metallic nature of composite-toe caps offers unique advantages that make them essential for specific jobs.

Critical for Electrical Hazard (EH) Zones

This is the most critical distinction. Because they are made from non-metallic materials, composite-toe boots do not conduct electricity. This makes them the only safe and acceptable choice for electricians or anyone working in an environment with a risk of contact with live electrical circuits.

Lighter Weight for Reduced Fatigue

Composite materials are significantly lighter than steel. This reduction in weight directly translates to less strain on your feet, legs, and back over the course of a long workday. For workers who are constantly walking or standing, this feature is essential for minimizing fatigue and improving comfort.

Understanding the Trade-offs

No single piece of equipment is perfect for every situation. Understanding the trade-offs of composite-toe boots ensures you are making the most informed decision.

Protection vs. Bulk

To achieve the same impact and compression rating as steel, a composite toe cap must often be slightly thicker or bulkier. This can affect the overall fit and profile of the boot, which is an important consideration for some users.

Flexibility and Feel

While far more protective, composite-toe boots are inherently more rigid and less flexible than standard soft-toe boots. This is a necessary trade-off for achieving the required level of safety in a hazardous workplace.

Making the Right Choice for Your Environment

Selecting the right boot depends entirely on the specific hazards and demands of your job.

- If your primary focus is working near electrical hazards: A composite-toe boot is non-negotiable for its essential non-conductive safety properties.

- If your primary focus is minimizing fatigue during long shifts: The lighter weight of a composite-toe boot makes it the superior choice for all-day comfort.

- If your primary focus is working in general construction or industrial roles: Both steel and composite toes offer certified protection, but composite provides the added benefits of being lightweight and suitable for all weather conditions.

Ultimately, choosing the right safety boot is about precisely matching the material's advantages to the unique risks of your workplace.

Summary Table:

| Industry / Environment | Primary Hazard Addressed | Why Composite Toe is Essential |

|---|---|---|

| Construction | Falling objects, compression | Certified impact protection; lighter than steel for reduced fatigue. |

| Manufacturing & Heavy Industry | Heavy machinery, rolling equipment | Meets strict safety standards; protects against crushing injuries. |

| Electrical Work (EH Zones) | Live electrical circuits | Non-metallic, non-conductive cap is critical for preventing electric shock. |

| Long-Duration Shifts | Worker fatigue | Significantly lighter weight minimizes leg and back strain over time. |

Ensure Your Team is Equipped with Essential Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear, including advanced composite-toe boots, for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots designed to meet the specific demands of high-risk industries.

We can help you:

- Source Reliable Safety Gear: Provide your workforce with boots that meet or exceed industry safety standards.

- Reduce Fatigue & Increase Productivity: Our lightweight composite-toe designs enhance comfort for long shifts.

- Mitigate Electrical Hazards: Offer your teams the essential non-conductive protection required for EH-rated environments.

Protect your most valuable asset—your people. Let's discuss your specific needs and how our manufacturing expertise can deliver the right safety solution for your business.

Contact 3515 today for bulk pricing, catalog requests, and custom manufacturing options.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture