Ultimately, the requirement for safety shoes is dictated by specific workplace hazards, not just industry titles. While many roles demand them, key industries where safety footwear is a standard and often legally mandated requirement include construction, manufacturing, logistics, oil and gas, and electrical work.

The decision to wear safety shoes is fundamentally about risk mitigation. The specific type of shoe required is always a direct response to the predictable, on-the-job hazards an employee faces, from falling objects and sharp debris to electrical currents and slippery surfaces.

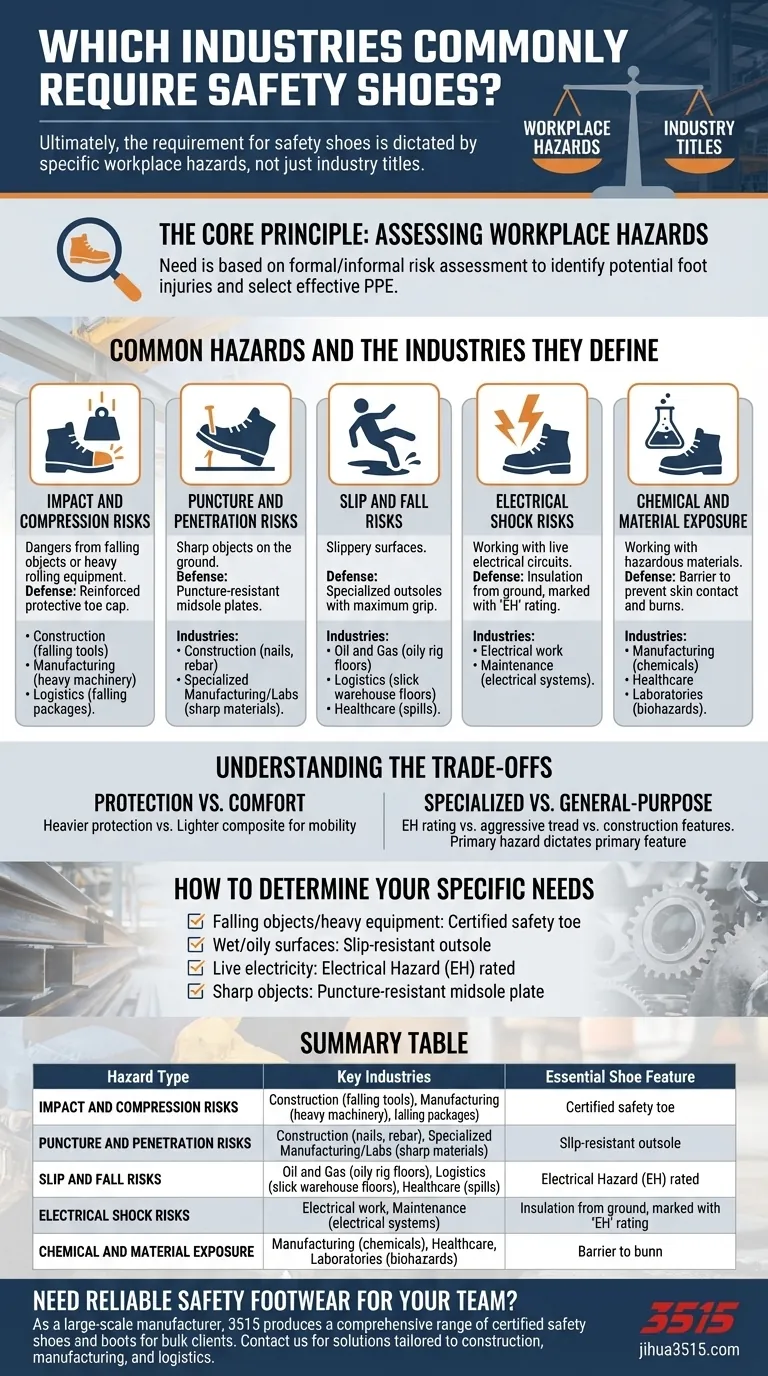

The Core Principle: Assessing Workplace Hazards

The need for safety footwear isn't arbitrary; it's the result of a formal or informal risk assessment. The goal is to identify potential foot injuries and select Personal Protective Equipment (PPE) that effectively neutralizes those threats. Understanding the specific danger is the first step to choosing the right protection.

Common Hazards and the Industries They Define

Different work environments present unique dangers. The industry serves as a shorthand for the types of hazards that are most prevalent.

Impact and Compression Risks

This category involves dangers from falling objects or heavy rolling equipment. The primary defense is a reinforced protective toe cap.

- Key Industries: Construction (falling tools, building materials), Manufacturing (heavy machinery, parts), and Logistics (falling packages, pallet jacks).

Puncture and Penetration Risks

Sharp objects on the ground pose a significant threat. Safety shoes designed for this have puncture-resistant plates in the midsole.

- Key Industries: Construction (nails, rebar, sharp debris) and specialized roles in Manufacturing or Laboratories where sharp materials are handled.

Slip and Fall Risks

Slippery surfaces are one of the most common causes of workplace injury. This requires footwear with specialized outsoles designed for maximum grip.

- Key Industries: Oil and Gas (oily rig floors), Logistics (slick warehouse floors), and Healthcare (spills on smooth flooring).

Electrical Shock Risks

For those working with live electrical circuits, footwear must provide insulation from the ground to prevent electric shock. These shoes are specifically marked with an "EH" rating.

- Key Industries: Electrical work and any maintenance roles involving electrical systems or high-voltage equipment.

Chemical and Material Exposure

When working with hazardous materials, the footwear must act as a barrier to prevent skin contact and chemical burns.

- Key Industries: Manufacturing (industrial chemicals), Healthcare, and Laboratories (biohazards, chemical spills).

Understanding the Trade-offs

Choosing safety footwear involves balancing protection with the demands of the job. There is no single "best" safety shoe, only the one best suited for a specific set of tasks.

Protection vs. Comfort and Mobility

Heavier protection, such as steel toe caps and metatarsal guards, offers maximum defense against impact but can make the shoe heavier and less flexible. Lighter composite toes offer good protection with less weight, which is often preferred for roles requiring constant walking.

Specialized vs. General-Purpose Features

A shoe with an EH rating for electrical hazards provides critical protection from shock but may not have the aggressive tread needed for an oily surface. A construction boot is excellent for impact and puncture but is often too heavy and cumbersome for a fast-paced logistics environment. The primary hazard should always dictate the primary feature.

How to Determine Your Specific Needs

To make the right choice, match the footwear's features directly to your most common workplace risks.

- If your primary risk is falling objects or heavy equipment: You need footwear with a certified safety toe (steel, alloy, or composite).

- If your primary risk is walking on wet or oily surfaces: You need shoes with a dedicated slip-resistant outsole.

- If your primary risk is working with live electricity: You must use footwear specifically rated for Electrical Hazard (EH) protection.

- If your primary risk is sharp objects on the ground: You need shoes with a puncture-resistant midsole plate.

Choosing the correct safety footwear is a foundational pillar of personal workplace safety.

Summary Table:

| Hazard Type | Key Industries | Essential Shoe Feature |

|---|---|---|

| Impact & Compression | Construction, Manufacturing, Logistics | Reinforced Safety Toe Cap |

| Puncture & Penetration | Construction, Manufacturing, Labs | Puncture-Resistant Midsole Plate |

| Slip & Fall | Oil & Gas, Logistics, Healthcare | Slip-Resistant Outsole |

| Electrical Shock | Electrical Work, Maintenance | EH (Electrical Hazard) Rating |

| Chemical Exposure | Manufacturing, Healthcare, Labs | Chemical-Resistant Material |

Need reliable safety footwear for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. We offer solutions tailored to the specific hazards of industries like construction, manufacturing, and logistics. Our production capabilities ensure you get durable, compliant, and comfortable footwear that protects your workforce. Contact us today for a quote and discover how we can meet your bulk safety footwear needs.

Visual Guide

Related Products

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What primary protective functions do industrial safety shoes provide? Maximize Safety in Heavy Machinery Maintenance

- How do industrial-grade safety shoes prevent accidents in freight handling? Grip, Stability & Injury Prevention

- What is the primary role of industrial safety shoes in the assembly of heavy iron pipes? Protect Against Impact & Puncture

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites