When selecting fully waterproof safety footwear, the distinction between S4 and S5 ratings comes down to two critical, environment-specific protections. An S5 safety boot includes all the features of an S4 boot but adds a penetration-resistant midsole and a cleated, slip-resistant outsole for enhanced protection against ground-level hazards.

The choice between S4 and S5 is not about finding a "better" boot, but about accurately matching the footwear's specific protections to the hazards of your work environment. S5 is designed for sites with puncture risks, while S4 is suited for wet conditions without sharp ground debris.

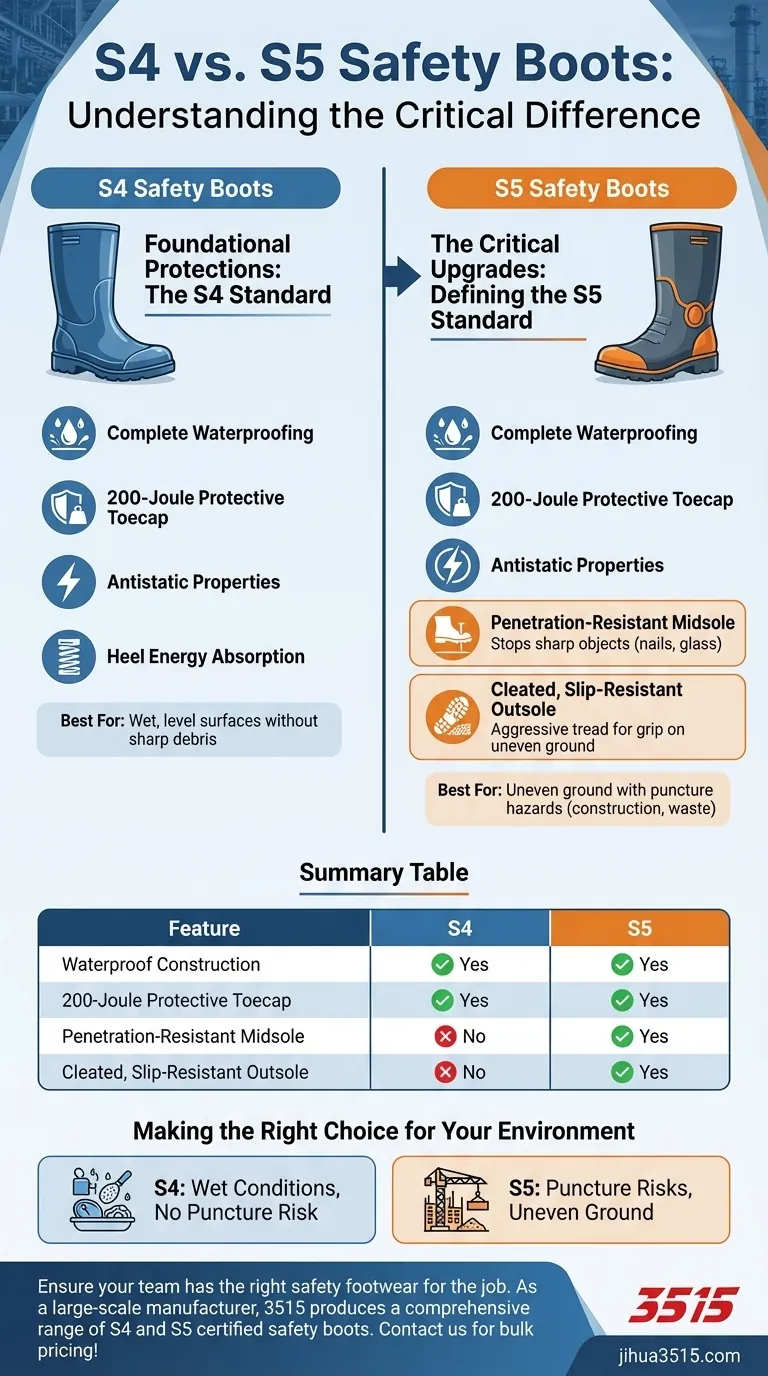

Foundational Protections: The S4 Standard

The S4 safety rating establishes the baseline for professional-grade waterproof footwear, typically in the form of rubber or polymer wellington boots. It combines total water resistance with fundamental safety features.

Complete Waterproofing

The defining feature of an S4 boot is its fully molded, leak-proof polymer or rubber construction, ensuring the wearer's feet stay completely dry in wet conditions.

Basic Impact Protection

Like most safety footwear, S4 boots include a 200-joule protective toecap to shield the foot from falling objects and compression.

Antistatic Properties

These boots are designed to dissipate electrostatic buildup, preventing the risk of static spark in sensitive environments.

Heel Energy Absorption

An energy-absorbing heel region cushions impact during walking, reducing fatigue and stress on the joints over long work periods.

The Critical Upgrades: Defining the S5 Standard

The S5 rating incorporates all S4 features and adds two specific protections that are vital in more hazardous, unpredictable environments like construction or waste management sites.

Penetration Resistance

This is the primary differentiator. S5 boots feature a penetration-resistant midsole (often steel or composite fabric) designed to stop sharp objects like nails, glass, or screws from piercing the sole and injuring the foot.

Cleated Outsole for Grip

S5 boots are required to have a cleated outsole. This aggressive tread pattern improves grip and stability on uneven, loose, or soft ground, significantly reducing the risk of slips and falls.

Understanding the Trade-offs

While S5 offers more protection, it is not automatically the right choice for every application. Understanding the context is key to making a sound decision.

Why Not Always Choose S5?

The added midsole plate can make the boot slightly heavier and less flexible than its S4 counterpart. In environments where puncture risks are non-existent, this adds unnecessary weight and potential fatigue.

Cost vs. Risk

S5 boots are typically more expensive due to the additional materials and manufacturing processes. The decision is a simple risk assessment: is the increased cost justified by the presence of puncture hazards on site? For many jobs, the answer is a clear yes.

Misinterpreting the Standard

It's crucial to remember that S4 and S5 ratings apply specifically to Class II rubber or polymeric footwear (wellingtons). The equivalent ratings for leather safety boots (Class I) are S2 and S3, where S3 adds the penetration-resistant midsole.

Making the Right Choice for Your Environment

Your specific workplace hazards should be the only factor in this decision.

- If your primary focus is working on wet, level surfaces with no sharp debris (e.g., food processing, agriculture, or industrial cleaning): An S4 boot provides the essential waterproof and safety features without the unnecessary cost and weight of a midsole.

- If your primary focus is working on construction sites, demolition zones, waste facilities, or any environment with potential ground hazards: The S5 rating is the mandatory minimum to protect against the clear and present danger of puncture injuries.

Choosing footwear with the correct safety rating is the foundational step in guaranteeing your protection at work.

Summary Table:

| Feature | S4 Safety Boots | S5 Safety Boots |

|---|---|---|

| Waterproof Construction | Yes | Yes |

| 200-Joule Protective Toecap | Yes | Yes |

| Penetration-Resistant Midsole | No | Yes |

| Cleated, Slip-Resistant Outsole | No | Yes |

| Best For | Wet, level surfaces without sharp debris | Uneven ground with puncture hazards (e.g., nails, glass) |

Ensure your team has the right safety footwear for the job. As a large-scale manufacturer, 3515 produces a comprehensive range of S4 and S5 certified safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring durability, compliance, and comfort. Protect your workforce with footwear built for their specific hazards—contact us today for expert guidance and bulk pricing!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job