To properly maintain your cowboy boots against wear and tear, you must regularly monitor the two most critical structural components: the soles and the heel caps. These areas bear the brunt of every step you take, and their condition dictates the longevity and integrity of the entire boot.

The key to making your boots last for decades is not constant cleaning, but systematic inspection. By focusing on the sole's integrity and the heel cap's wear level, you can preemptively address small issues before they become catastrophic and costly failures.

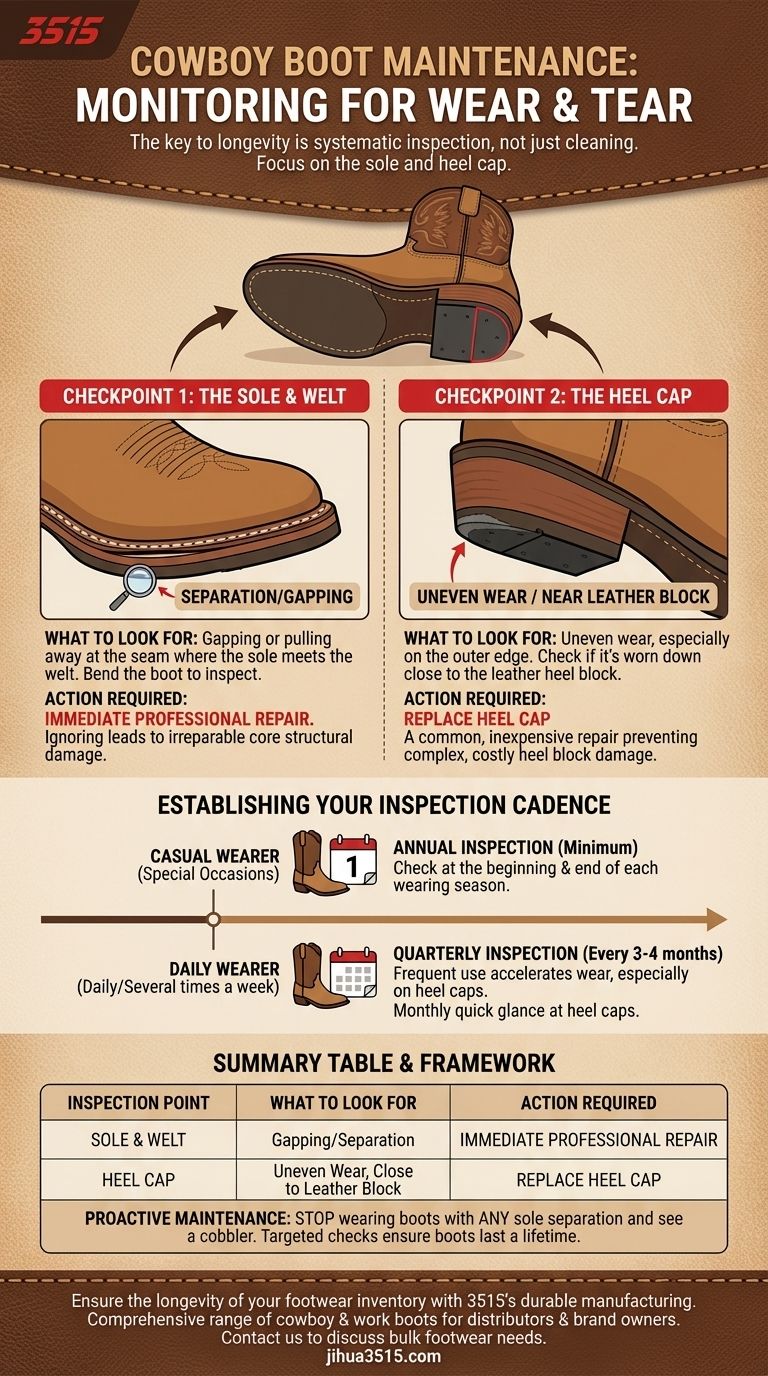

The Two Critical Wear Points on Your Boots

While the entire boot deserves care, the sole and heel are the foundation. Problems here compromise everything else. A regular inspection, even a quick one, is the most effective maintenance you can perform.

Checkpoint 1: The Sole and Welt

The sole is the bottom of your boot, and the welt is the strip of leather (often with visible stitching) that attaches the sole to the upper part of the boot. This connection is the boot's structural backbone.

Your primary goal is to look for separation. Carefully bend the boot and inspect the seam where the sole meets the welt. If you see any gapping or pulling away, this is a serious issue that requires immediate professional attention.

Ignoring a separating sole can lead to irreparable damage to the boot's core structure.

Checkpoint 2: The Heel Cap

The heel cap is the rubber piece at the very bottom of the heel. It is a sacrificial component, designed to wear down so the leather heel block above it does not.

Heel caps wear out much faster than the sole. Check them for uneven wear, especially on the outer edge. Once the cap has worn down close to the leather of the heel block, it's time for a replacement.

This is a common and relatively inexpensive repair that prevents a much more complex and costly heel block replacement down the line.

Establishing Your Inspection Cadence

How often you need to inspect your boots depends entirely on how often you wear them. Time is less important than mileage.

The Baseline Assessment

For any pair of boots, a thorough inspection at least once a year is the absolute minimum. This is sufficient for boots worn only on special occasions.

Adjusting for Usage

If you wear your boots daily or several times a week, a quarterly inspection (every 3-4 months) is a much safer cadence. Frequent use accelerates wear significantly, especially on heel caps.

Understanding the Trade-offs: Repair vs. Neglect

Proactive maintenance is about making small, affordable investments to avoid large, expensive ones.

The Cost of Neglect

Letting a heel cap wear completely through to the leather heel block can turn a simple $20-$40 repair into one costing over $100. The damage to the core leather structure requires a more intensive fix.

Similarly, continuing to wear boots with a separating sole can damage the welt and the leather upper, potentially making the boots impossible to resole properly.

When to See a Professional

Some things are not DIY projects. If you see any separation between the sole and the welt, take the boots to a qualified cobbler immediately. While some may attempt to replace their own heel caps, a cobbler will ensure they are perfectly level and securely attached, which is critical for your comfort and the boot's longevity.

A Simple Maintenance Framework

Use these guidelines to create a habit of proactive inspection.

- If you are a casual wearer: Perform a thorough inspection of the soles and heels at the beginning and end of each season you wear them.

- If you are a daily wearer: Give your heel caps a quick glance monthly and perform a full sole and welt inspection every three months.

- If you notice any separation between the layers of your sole: Stop wearing the boots and take them to a professional cobbler for assessment.

These simple, targeted checks are the single most important factor in ensuring your boots last a lifetime.

Summary Table:

| Inspection Point | What to Look For | Action Required |

|---|---|---|

| Sole & Welt | Gapping or separation between sole and welt | Immediate professional repair |

| Heel Cap | Uneven wear, close to leather heel block | Replace heel cap |

| Inspection Cadence | Casual Wearer: Annually / Daily Wearer: Quarterly | Regular visual checks |

Ensure the longevity of your footwear inventory with 3515's durable manufacturing.

As a large-scale manufacturer, 3515 produces a comprehensive range of cowboy boots, work boots, and other footwear built for durability. Our production capabilities are tailored for distributors, brand owners, and bulk clients who demand quality that reduces long-term maintenance costs for their customers.

Contact us today to discuss your bulk footwear needs and partner with a manufacturer dedicated to structural integrity and longevity.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How should work boots fit properly? A Guide to All-Day Comfort and Safety

- What risks do women face when wearing ill-fitting work boots in construction? Protect Your Health & Safety

- What safety boots are recommended for the oil and gas industry? Essential Features for Hazardous Sites

- How do Western work boots blend tradition with modern fashion? A Guide to Stylish Durability

- What are the characteristics of rubber work boots? Unmatched Waterproofing for Wet & Chemical Environments

- What are the potential drawbacks of Western work boots? Weighing Convenience Against Support

- Do OSHA standards apply to safety boots as well? Ensuring Complete Workplace Foot Protection

- What safety features are typically found in Western work boots? Your Essential Guide to On-Site Protection