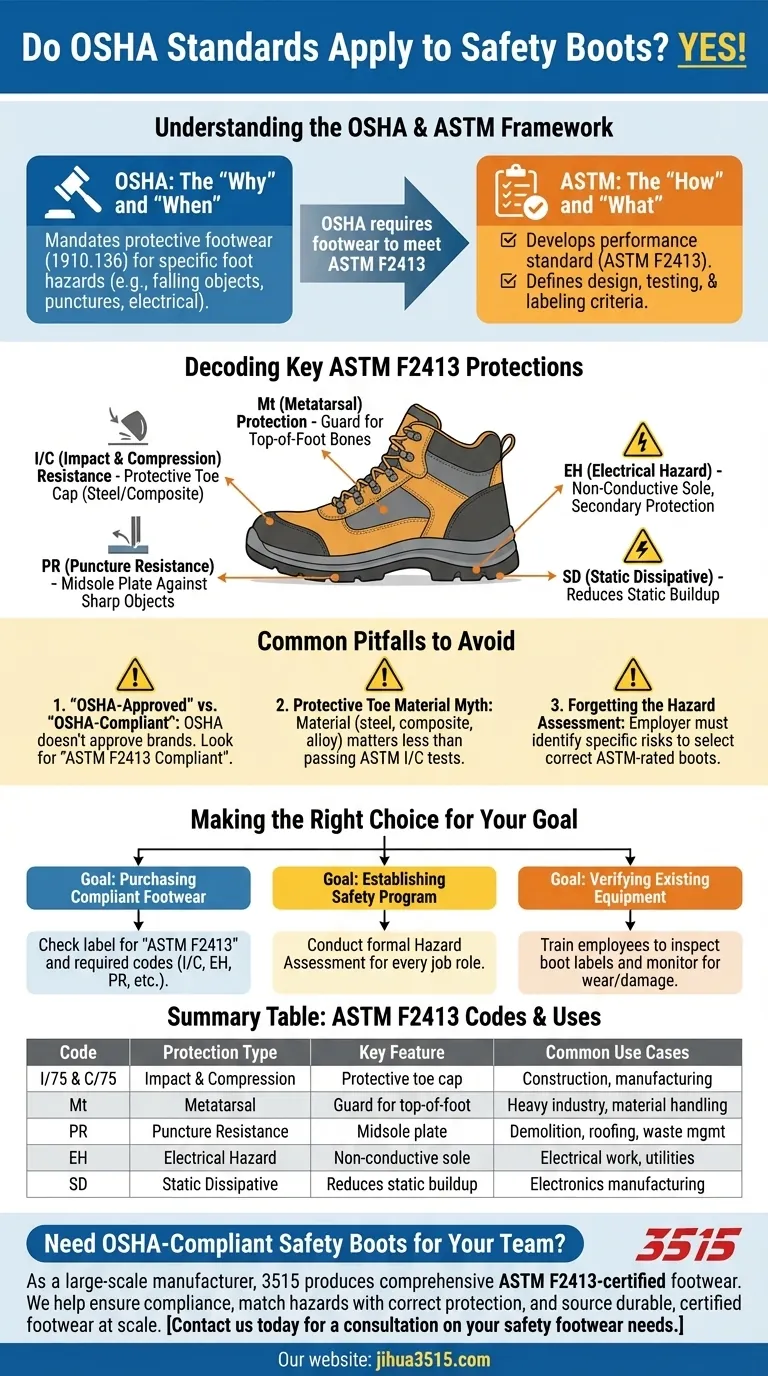

Yes, OSHA standards absolutely apply to safety boots. The Occupational Safety and Health Administration (OSHA) mandates protective footwear in any workplace where there is a danger of foot injuries. However, OSHA itself does not test or certify boots; instead, it requires that safety footwear meets the specific performance standards developed by organizations like ASTM International.

The core relationship to understand is this: OSHA sets the requirement for when protective footwear must be used, while the ASTM F2413 standard defines the specific performance criteria that a boot must meet to be considered compliant.

The OSHA and ASTM Framework Explained

To ensure workplace safety, it's crucial to understand how these two organizations work together. One creates the rule, and the other creates the benchmark for quality and performance.

OSHA's Role: The "Why" and "When"

OSHA standard 1910.136 dictates that employers must require employees to use protective footwear when they are working in areas with potential foot hazards.

These hazards include falling or rolling objects, objects that could pierce the sole of the shoe, and exposure to electrical hazards. OSHA’s role is to enforce this requirement through workplace assessments and inspections.

ASTM's Role: The "How" and "What"

ASTM International (formerly the American Society for Testing and Materials) develops the technical standards for a vast range of products, including Personal Protective Equipment (PPE).

The key standard for safety footwear is ASTM F2413. This document specifies the minimum requirements for the design, performance, testing, and labeling of protective footwear. A boot that meets this standard is considered OSHA-compliant.

Decoding Key ASTM F2413 Protections

When you look at a compliant safety boot, you'll see a label referencing ASTM F2413 followed by a series of codes. These codes identify the specific hazards the boot protects against.

Impact (I) and Compression (C) Resistance

This is the most fundamental feature, often associated with a "steel toe." The protective toe cap can be made of steel, composite materials, or aluminum alloys.

The Impact (I) rating tests the toe cap's ability to protect against a heavy object falling on it. The Compression (C) rating tests its ability to withstand a heavy object rolling over it.

Metatarsal (Mt) Protection

Some boots include an integrated metatarsal guard that protects the delicate bones on the top of the foot from impact. This is critical in environments where objects could drop directly onto the foot's instep.

Puncture Resistance (PR)

These boots have a puncture-resistant plate built into the midsole, directly beneath the foot. This is essential for work sites where sharp objects like nails, scrap metal, or glass could pierce the sole of the boot.

Electrical Hazard (EH) Protection

Footwear with an EH rating is designed with non-conductive, shock-resistant soles and heels. This provides a secondary source of protection against accidental contact with live electrical circuits.

Static Dissipative (SD) Performance

SD footwear is designed to reduce the buildup of static electricity by conducting it safely to the ground. This is vital in environments where a static discharge could damage sensitive electronics or ignite flammable materials.

Common Pitfalls to Avoid

Navigating safety standards can be confusing. Understanding these common points of error will ensure you make the right decisions for your team.

"OSHA-Approved" vs. "OSHA-Compliant"

OSHA does not approve, certify, or endorse any specific brand or model of safety boot. A boot is "OSHA-compliant" because it meets the third-party standard (ASTM F2413) that OSHA requires. Be wary of any marketing that claims a boot is "OSHA-Approved."

The Protective Toe Material Myth

The standard does not mandate a specific material for the protective toe cap. Whether it's steel, composite, or alloy, what matters is that it passes the ASTM impact and compression tests. Composite toes are often lighter and don't conduct cold, but the level of protection is defined by the rating, not the material.

Forgetting the Hazard Assessment

It is the employer's legal responsibility to perform a thorough hazard assessment of the workplace. You cannot simply buy "safety boots"; you must identify the specific risks (e.g., puncture, electrical, impact) and select footwear with the corresponding ASTM ratings to protect your employees properly.

Making the Right Choice for Your Goal

Selecting the correct footwear is a critical safety decision. Use your specific objective to guide your actions.

- If your primary focus is purchasing compliant footwear: Look for a label inside the boot that explicitly states it conforms to ASTM F2413 and lists the codes for the specific protections you need (e.g., I/75, C/75, EH, PR).

- If your primary focus is establishing a safety program: Conduct and document a formal hazard assessment for every job role to determine the precise foot dangers your employees face.

- If your primary focus is verifying existing equipment: Train employees to understand the ASTM labels inside their footwear and to regularly inspect their boots for wear, tear, and damage that could compromise their protective features.

Understanding this framework empowers you to move from simply buying safety boots to strategically selecting the correct protection for the specific risks your team faces.

Summary Table:

| ASTM F2413 Code | Protection Type | Key Feature | Common Use Cases |

|---|---|---|---|

| I/75 & C/75 | Impact & Compression | Protective toe cap (steel/composite) | Construction, manufacturing, warehousing |

| Mt | Metatarsal | Guard for top-of-foot bones | Heavy industry, material handling |

| PR | Puncture Resistance | Midsole plate | Demolition, roofing, waste management |

| EH | Electrical Hazard | Non-conductive sole | Electrical work, utilities |

| SD | Static Dissipative | Reduces static buildup | Electronics manufacturing, flammable environments |

Need OSHA-compliant safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots with precise ratings for impact, compression, puncture, and electrical hazards.

We help you:

- Ensure full compliance with OSHA standards

- Match specific workplace hazards with correct protection

- Source durable, certified footwear at scale

Contact us today for a consultation on your safety footwear needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.