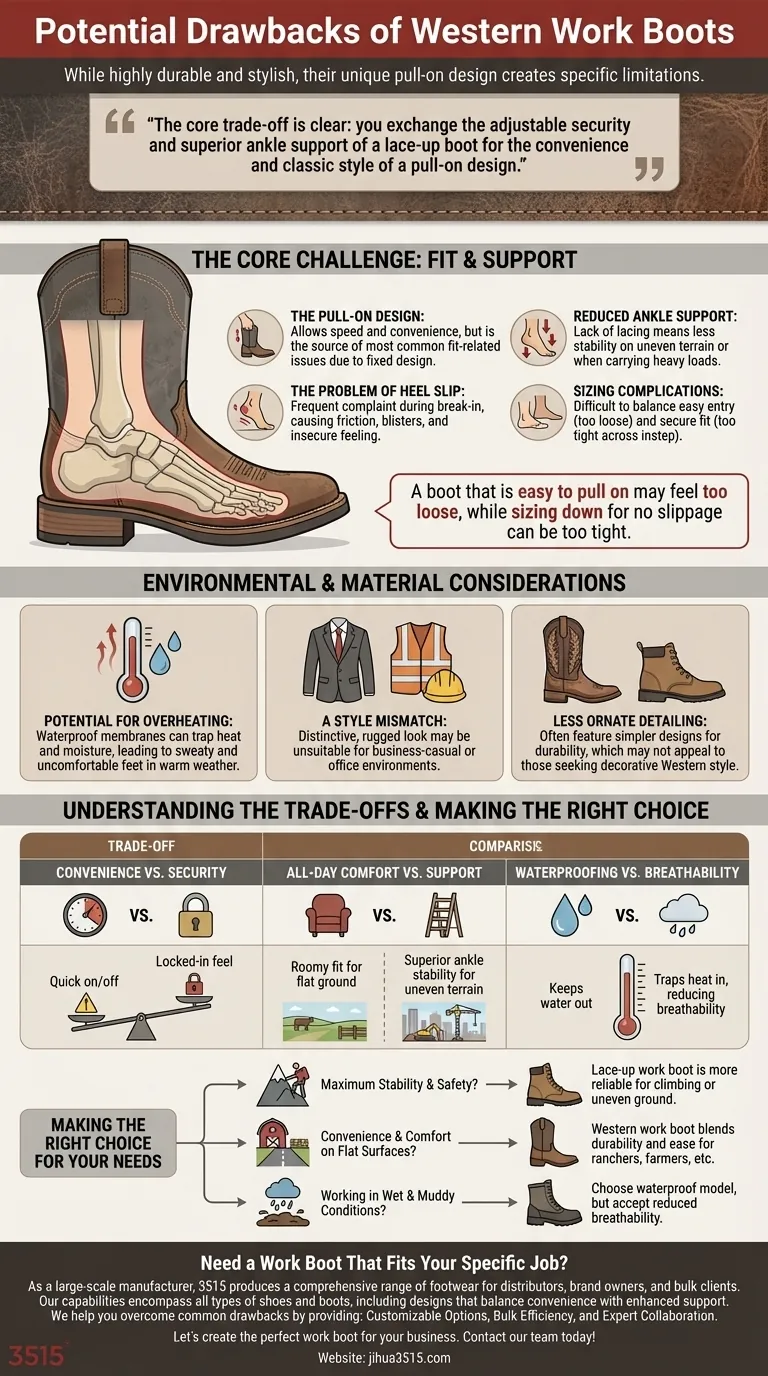

While highly durable and stylish, the primary drawbacks of Western work boots stem directly from their pull-on design. This can lead to a looser fit with less ankle support compared to lace-up boots, potential for heel slip, and a rugged aesthetic that may not be suitable for every professional environment.

The core trade-off with a Western work boot is clear: you are exchanging the adjustable security and superior ankle support of a lace-up boot for the convenience and classic style of a pull-on design.

The Core Challenge: Fit and Support

The most significant functional drawbacks of Western work boots are tied to their construction. Unlike boots with laces, they offer a fixed fit that cannot be adjusted throughout the day.

The Pull-On Design

A Western work boot's defining feature is its pull-on nature. This allows for speed and convenience but is also the source of its most common fit-related issues.

Reduced Ankle Support

The lack of a lacing system means the boot cannot be tightened around the ankle. This provides significantly less support, which can be a safety concern when walking on uneven terrain, carrying heavy loads, or climbing.

The Problem of Heel Slip

Heel slip, where your heel lifts inside the boot as you walk, is a frequent complaint, especially during the break-in period. This can cause friction, leading to blisters and an insecure feeling.

Sizing Complications

Achieving the perfect fit can be difficult. A boot that is easy to pull on may feel too loose around the foot, while sizing down to prevent slippage can make the boot uncomfortably tight across the instep.

Environmental and Material Considerations

Beyond the fit, other factors related to the boot's materials and intended use can present challenges for some wearers.

Potential for Overheating

Many modern Western work boots include a waterproof membrane. While excellent for keeping water out, these liners can trap heat and moisture, leading to sweaty and uncomfortable feet during long hours or in warm weather.

A Style Mismatch

The distinctive, rugged style is a major appeal, but it can also be a limitation. These boots often look out of place in business-casual or office environments where a more traditional work boot might blend in.

Less Ornate Detailing

Compared to traditional cowboy boots, Western work boots often feature less elaborate stitching and simpler designs. This is a functional choice for durability, but may be a drawback for those seeking a more decorative Western style.

Understanding the Trade-offs

Choosing a Western work boot means weighing its unique benefits against its inherent compromises. Your specific work environment and daily tasks should guide your decision.

Convenience vs. Security

The ability to pull your boots on and off in seconds is a major advantage. However, this convenience comes at the cost of the locked-in, secure feeling provided by a tightly laced boot.

All-Day Comfort on a Ranch vs. A Construction Site

For long hours of walking or standing on relatively even ground, the roomy fit of a Western work boot can be very comfortable. For jobs involving ladders, scaffolding, or steep inclines, the superior ankle support of a lace-up boot is often a non-negotiable safety feature.

Waterproofing vs. Breathability

A waterproof lining is essential in wet climates, but it will always reduce breathability. If you work primarily in dry, hot conditions, a non-waterproof leather boot may provide far greater long-term comfort.

Making the Right Choice for Your Needs

To decide if a Western work boot is right for you, evaluate your primary requirements.

- If your primary focus is maximum stability and safety: A traditional lace-up work boot is the more reliable choice, especially for climbing or traversing highly uneven ground.

- If your primary focus is convenience and comfort on flatter surfaces: A well-fitted Western work boot is an excellent option, blending durability with ease of use for ranchers, farmers, or workshop professionals.

- If your primary focus is working in wet and muddy conditions: Choose a model with a reliable waterproof membrane, but be aware of the trade-off in breathability.

Understanding these inherent trade-offs is the key to choosing a boot that serves your needs without compromise.

Summary Table:

| Drawback | Key Impact | Ideal For |

|---|---|---|

| Pull-On Design | Less adjustable fit, potential heel slip | Ranchers, farmers, flat terrain work |

| Reduced Ankle Support | Less stability on uneven ground | Workshop professionals, light-duty tasks |

| Style & Breathability | Rugged look; waterproof models can be less breathable | Casual settings; dry/wet condition-specific use |

Need a Work Boot That Fits Your Specific Job?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including specialized designs that balance the classic convenience of a Western boot with enhanced support and a perfect fit.

We help you overcome common drawbacks by providing:

- Customizable Options: Tailor boot features like ankle support, breathability, and style to match your target market's needs.

- Bulk Efficiency: Streamline your supply chain with reliable, high-volume production of durable work boots.

- Expert Collaboration: Work with our team to develop or source the ideal footwear solution for your customers.

Let's create the perfect work boot for your business. Contact our team today to discuss your requirements!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Why is the use of specialized work boots with high comfort levels necessary for welding? Enhance Safety and Endurance

- How did engineer boots evolve from workwear to fashion items? A Symbol of Rebellion and Style

- Which type of work boot is recommended if someone is undecided between lace up and pull on? Choose for Safety & Fit

- What safety standards do composite toe work boots typically meet? Essential ASTM F2413 Guide

- How are engineer boots typically styled? Master the Rugged, Timeless Look

- Why are slip-resistant soles important in work boots? Prevent Slips & Boost Safety

- What should you look for in terms of durability when selecting PVC work boots? Ensure Long-Lasting Protection

- What is the most important factor to consider when purchasing new work boots? Align Safety with Your Job's Demands