First, I need to understand the user's needs. They're likely professionals looking for guidance, not just casual shoppers. The question isn't just "What are the features?", it's "Why are these features important for my safety at work, and how do I choose the right boot?" I'll start by deconstructing the question, considering the technical references, and planning a clear, scannable structure.

My strategy is to be a trusted resource, providing objective and unbiased information to their specific problem. I'll stick closely to the sources, but I will organize it in a more helpful way. I will use H2 and H3 headings to break down the information so it's super easy to read and understand. I'll focus on the essential safety features – safety toes, puncture plates, slip-resistant outsoles, and EH ratings – and explain how they relate to real-world hazards. Comfort will be addressed too, but in relation to safety.

I'll keep the tone calm and objective, with simple language. The language will also include a "Trade-Offs" section, to address decision-making, in the specific context of Western work boots.

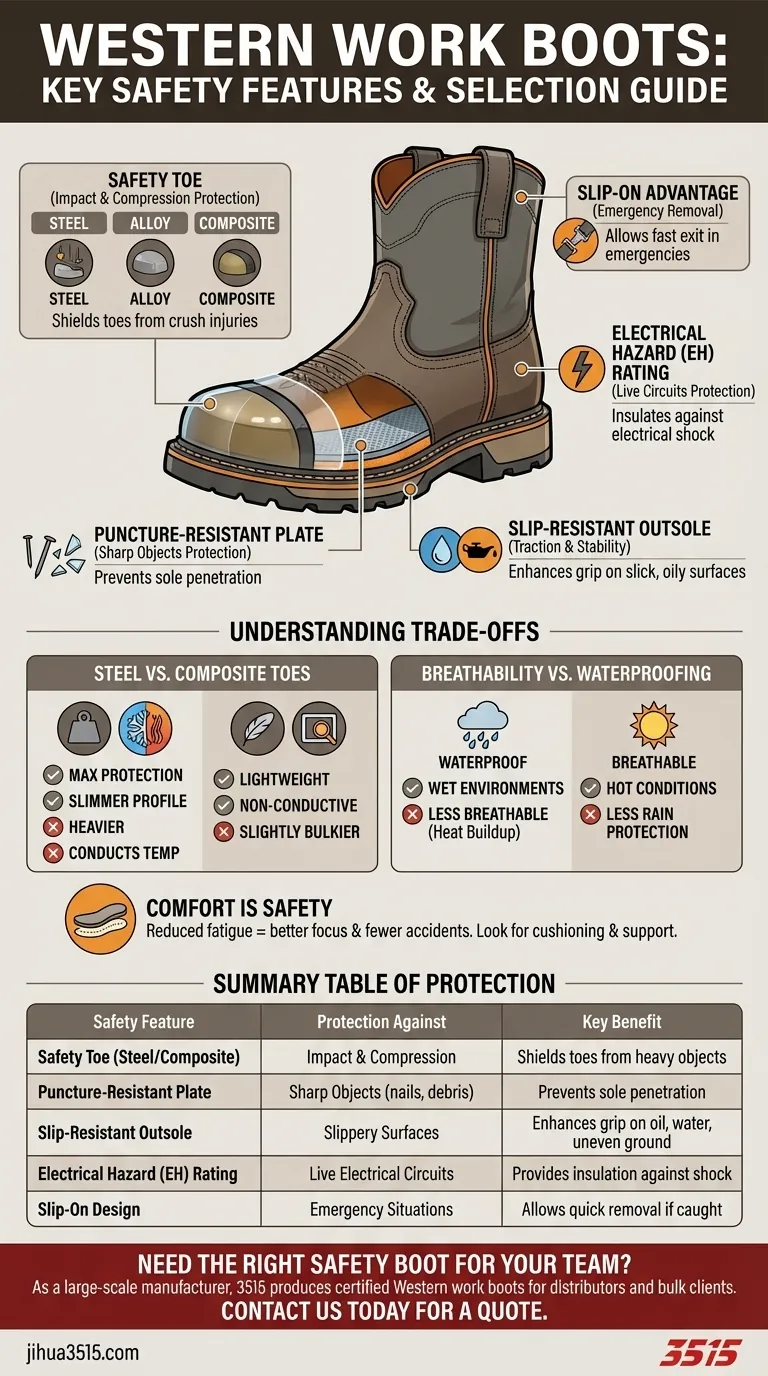

The final structure is planned: an opening hook with a direct answer, a core takeaway box for a quick summary, a detailed breakdown with clear headings, and a concluding section with actionable advice. It's a structured approach that goes beyond listing features to providing usable knowledge. This includes how each feature protects from certain hazards, how to compare and contrast options, and how to choose the right boot for specific work environments. I want to empower the user to make an informed, safe choice. At their core, Western work boots integrate four critical safety technologies into a traditional slip-on design. These features include reinforced safety toes (steel, composite, or alloy) to protect against impact, puncture-resistant plates in the sole, high-traction slip-resistant outsoles, and non-conductive materials for Electrical Hazard (EH) protection.

The most effective Western work boot isn't the one with the most features, but the one whose specific protections are correctly matched to the known hazards of your work environment. Understanding this distinction is the key to true on-the-job safety.

Core Protective Features Explained

The functional design of a Western work boot is built upon a foundation of specific safety components. Each element is engineered to mitigate a common worksite hazard, from falling objects to unseen sharps underfoot.

Impact and Compression Protection (Safety Toes)

The most well-known safety feature is the reinforced toe cap. This component shields your toes from being crushed by heavy equipment or falling materials.

There are three primary types: steel, alloy (like aluminum or titanium), and composite (non-metallic materials like carbon fiber or Kevlar). All are rated to meet the same safety standards.

Puncture Resistance (Underfoot Plates)

Many work environments, especially construction and demolition sites, have sharp objects like nails, screws, and metal shards on the ground.

A puncture-resistant plate is a protective layer built into the midsole of the boot, directly beneath your foot. This plate prevents sharp objects from piercing the sole and causing serious injury.

Traction and Stability (Slip-Resistant Outsoles)

Slips, trips, and falls are among the most common workplace accidents. Western work boots address this with slip-resistant rubber outsoles.

These outsoles feature specialized tread patterns designed to channel away water, oil, and other liquids, ensuring a firm grip on slick or uneven surfaces.

Electrical Hazard (EH) Protection

For anyone working near live electrical circuits, Electrical Hazard (EH) rated boots are essential.

These boots are constructed with non-conductive soles and heels that can withstand an electrical shock, providing a critical layer of insulation against accidental contact.

The Slip-On Advantage

Unlike lace-up boots, the traditional slip-on design of a Western boot allows for quick and easy removal. In an emergency, such as a chemical spill or if the boot becomes caught in machinery, this can be a significant safety advantage.

Understanding the Trade-offs

Choosing the right boot involves more than just a list of features; it requires understanding the compromises inherent in their design.

Steel vs. Composite Toes

This is a classic decision point. Steel toes offer maximum protection in a slim profile but are heavier and conduct heat and cold.

Composite toes are much lighter, don't conduct temperature, and won't set off metal detectors, but they can be slightly bulkier to achieve the same safety rating.

Breathability vs. Waterproofing

A fully waterproof boot is excellent for wet environments but will inherently be less breathable. This can lead to heat and moisture buildup inside the boot during a long day.

Conversely, a more breathable boot offers superior comfort in hot conditions but will provide less protection from rain or standing water. Your daily work environment should dictate which is more important.

Comfort as a Safety Feature

Do not dismiss comfort as a mere luxury. Features like cushioned insoles, molded footbeds, and proper arch support are crucial for safety.

Fatigue is a leading cause of workplace accidents. A boot that reduces physical strain and keeps you comfortable allows you to stay more alert and focused on your tasks.

Making the Right Choice for Your Worksite

To select the ideal boot, analyze your environment and prioritize the features that directly counter the hazards you face most often.

- If your primary focus is protection from heavy falling objects: Prioritize a high-quality steel or alloy safety toe for maximum impact resistance.

- If your primary focus is working around live electricity: You must select a boot with a certified Electrical Hazard (EH) rating.

- If your primary focus is navigating slippery or oily surfaces: A high-traction, slip-resistant rubber outsole is non-negotiable.

- If your primary focus is construction or demolition sites: Ensure the boot includes a puncture-resistant plate to protect your soles from nails and debris.

Equipping yourself with the right boot is the foundational step toward a safer and more productive day on the job.

Summary Table:

| Safety Feature | Protection Against | Key Benefit |

|---|---|---|

| Safety Toe (Steel/Composite) | Impact & Compression | Shields toes from heavy objects |

| Puncture-Resistant Plate | Sharp Objects (nails, debris) | Prevents sole penetration |

| Slip-Resistant Outsole | Slippery Surfaces | Enhances grip on oil, water, and uneven ground |

| Electrical Hazard (EH) Rating | Live Electrical Circuits | Provides insulation against shock |

| Slip-On Design | Emergency Situations | Allows for quick removal if caught or contaminated |

Need the right safety boot for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of certified Western work boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, compliant footwear that meets your specific worksite hazards. Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What should you check when shopping for non-conductive work boots? Verify the EH Rating for Maximum Safety

- Why is attention to detail important in the design of western boots? It's the Key to Authenticity & Quality

- Why are certifications important for firefighter boots? Your Non-Negotiable Safety Guarantee

- What are the decontamination challenges with leather boots compared to rubber? The Critical Safety Difference

- In what way do energy-absorbing heels and cushioning midsoles help mitigate fatigue? Boost Industrial Worker Productivity

- How can moc toe boots be styled for casual wear? Master Rugged & Modern Looks

- What are some user experiences with packer boots? Unmatched Durability & All-Day Comfort

- What features should workers in muddy conditions look for in work boots? | The Ultimate Guide