At their core, comfortable work boots integrate critical safety features by using advanced materials and thoughtful design. Key protections include composite or steel toes for impact resistance, puncture-resistant soles to guard against sharp objects, and Electrical Hazard (EH) ratings to protect against open circuits, all within a lightweight and ergonomic structure.

The most effective work boot isn't just the one with the most safety features; it's the one with the right safety features for your specific job, engineered to provide certified protection without causing unnecessary fatigue.

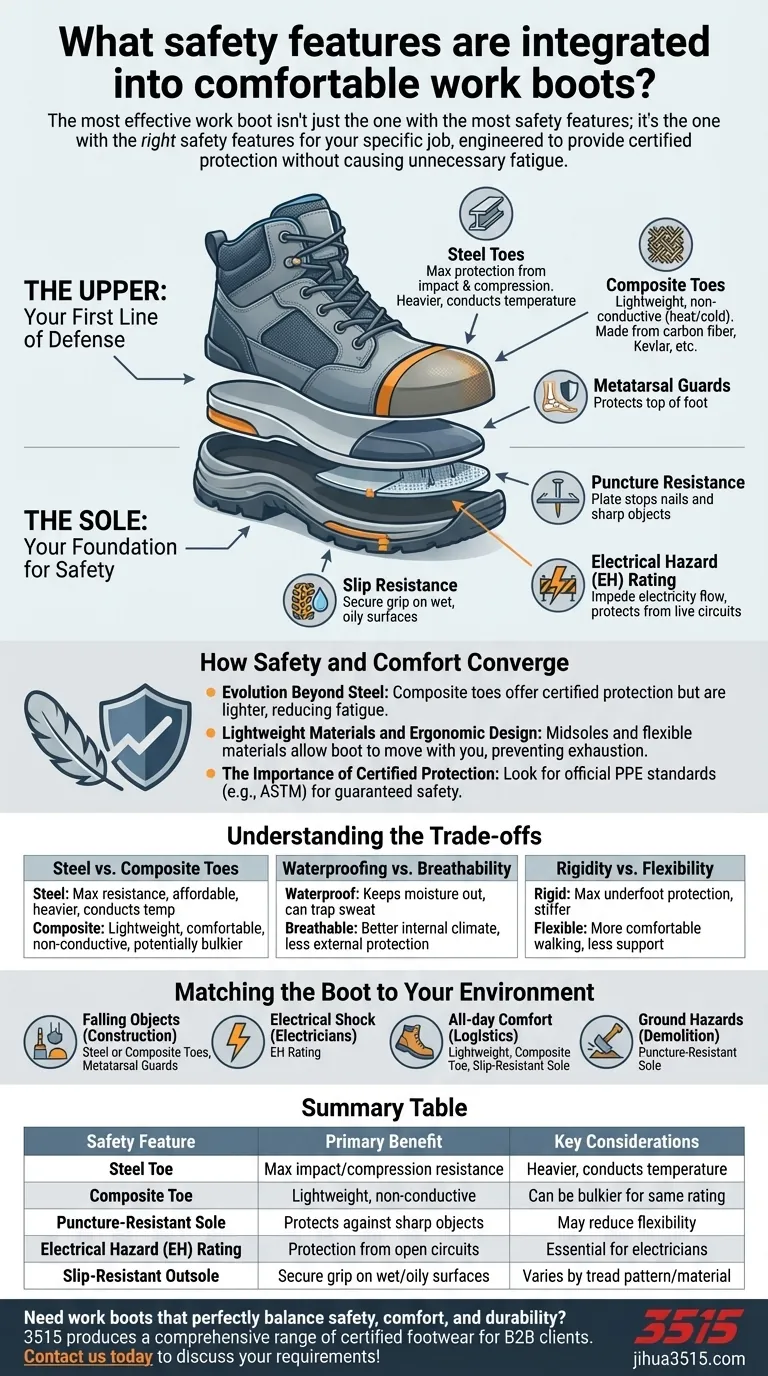

Deconstructing the Modern Safety Boot

To understand how comfort and safety coexist, it's helpful to see a boot as a system of protective layers, each with a specific job. These are generally divided into the upper section and the sole.

The Upper: Your First Line of Defense

The upper part of the boot shields the top and sides of your foot. It contains the most well-known safety feature: the protective toe cap, which must meet certified standards for impact and compression resistance.

You will typically find two main types:

- Steel Toes: The traditional standard for maximum protection against crushing and impact.

- Composite Toes: Made from non-metal materials like carbon fiber, Kevlar, or plastic. They are lighter and do not conduct heat or cold, significantly enhancing comfort.

Beyond the toe, features like metatarsal guards can offer protection to the top of your foot, while specialized upper materials can provide resistance to chemicals or water.

The Sole: Your Foundation for Safety

The sole is your connection to the ground and is engineered for more than just walking. A boot's sole provides crucial, often unseen, protection.

Key safety features here include:

- Puncture Resistance: A protective plate is placed within the sole to stop nails and other sharp objects from penetrating the boot.

- Slip Resistance: Outsole materials and tread patterns are designed and tested to provide a secure grip on wet, oily, or uneven surfaces.

- Electrical Hazard (EH) Rating: Specialized soles are constructed to impede the flow of electricity, offering a secondary source of protection from live circuits.

Construction: The Unseen Protectors

The way a boot is built contributes significantly to its safety and longevity. Durable elements like triple-stitching and high-quality leather or synthetic uppers ensure the boot doesn't fail under stress. Features like waterproofing and insulation protect you from environmental hazards while also contributing to comfort.

How Safety and Comfort Converge

The idea that a boot must be heavy and rigid to be safe is outdated. Modern material science and design have closed the gap between protection and wearability.

The Evolution Beyond Steel

While steel toes offer exceptional strength, composite toes are a major reason modern boots can be both safe and comfortable. They provide certified protection while being significantly lighter, which reduces foot fatigue over a long workday.

Because they don't conduct electricity or temperature, composite materials are also ideal for those working in extreme cold, heat, or around electrical hazards.

Lightweight Materials and Ergonomic Design

Safety no longer comes at the cost of weight. Lightweight midsoles, composite safety toes, and flexible materials allow for the construction of a boot that moves with you. This ergonomic approach prevents the exhaustion and discomfort that heavy, clunky boots can cause.

The Importance of Certified Protection

Always look for boots that meet official Personal Protective Equipment (PPE) standards, such as those from ASTM International (formerly the American Society for Testing and Materials).

Certification ensures that a boot has passed rigorous, standardized tests for impact resistance, compression, and other safety metrics. This is your guarantee that even a lightweight, comfortable boot provides real, dependable protection.

Understanding the Trade-offs

Choosing the right boot involves balancing competing factors. An objective understanding of these trade-offs is essential for making the right choice.

Steel Toes vs. Composite Toes

Steel offers the absolute maximum in impact and compression resistance and is often more affordable. However, it is heavier and conducts temperature. Composite is lighter and more comfortable in varying temperatures but can sometimes be bulkier to achieve the same safety rating.

Waterproofing vs. Breathability

A fully waterproof boot is excellent for keeping external moisture out. However, the membrane that blocks water can sometimes trap sweat, leading to discomfort. The trade-off is often between protection from the elements and internal climate control.

Rigidity vs. Flexibility

A highly rigid, puncture-proof sole provides maximum underfoot protection but may feel stiff and unforgiving. A more flexible sole will be more comfortable for walking but may not offer the same level of support or protection on rough terrain.

Matching the Boot to Your Environment

The final decision should always be based on the primary hazards of your job.

- If your primary focus is protection from falling objects (construction, heavy industry): Prioritize certified steel or composite toes and consider adding metatarsal guards.

- If your primary focus is protection from electrical shock (electricians): An Electrical Hazard (EH) rating is non-negotiable and should be your first priority.

- If your primary focus is all-day comfort and mobility (manufacturing, logistics): A lightweight boot with a composite toe and a high-quality, slip-resistant sole is the ideal choice.

- If your primary focus is protection from ground hazards (demolition, waste management): A puncture-resistant sole is absolutely essential.

By aligning a boot's specific features with your daily risks, you ensure you are protected, comfortable, and focused on the task at hand.

Summary Table:

| Safety Feature | Primary Benefit | Key Considerations |

|---|---|---|

| Steel Toe | Maximum impact/compression resistance | Heavier, conducts temperature |

| Composite Toe | Lightweight, non-conductive (heat/cold) | Can be bulkier for same rating |

| Puncture-Resistant Sole | Protects against sharp objects | May reduce flexibility |

| Electrical Hazard (EH) Rating | Protection from open circuits | Essential for electricians |

| Slip-Resistant Outsole | Secure grip on wet/oily surfaces | Varies by tread pattern and material |

Need work boots that perfectly balance safety, comfort, and durability? As a large-scale manufacturer, 3515 produces a comprehensive range of certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, tailored to your specific job hazards and comfort needs. Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How do composite toe work boots handle moisture? Stay Dry and Comfortable in Wet Conditions

- How do mining boots provide electrical hazard protection? Essential Safety for Electrical Work

- What are the specific footwear requirements for workers in the logging industry? Ensure Safety and Stability on Rough Terrain

- Why is electrical hazard protection required on some job sites? Essential Safety for High-Risk Environments

- What is a metatarsal guard in Wellington work boots? Essential Protection for High-Risk Jobs

- What are the three main types of work boot construction? Choose the Right Boot for Your Job

- What safety features should hazard workers look for in lace-up work boots? A Guide to Certified Protection

- What features should warehouse workers look for in work boots? Prioritize Safety, Slip Resistance & All-Day Comfort