For any hazard worker, the right lace-up work boot is a critical piece of personal protective equipment, not just footwear. The essential safety features to look for are a certified protective toe, a puncture-resistant plate, a slip-resistant outsole, and appropriate protection against electrical hazards. Robust ankle support, inherent in a well-designed lace-up boot, provides the structural integrity needed for stability on unpredictable surfaces.

The most effective safety boot isn't the one with the most features, but the one with the correct, certified combination of features specifically chosen to mitigate the known risks of your work environment.

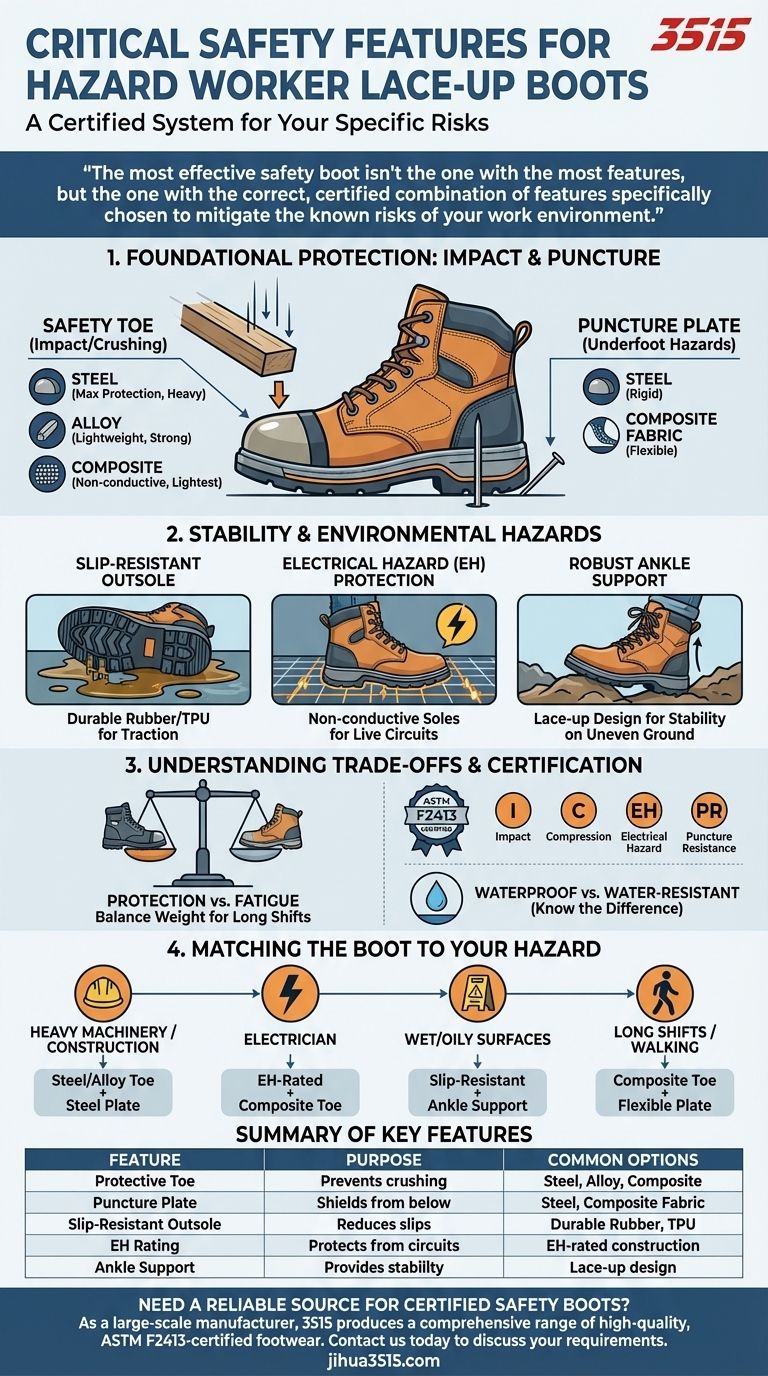

Foundational Protection: Impact and Puncture

Your feet are exposed to two primary mechanical risks on a hazardous worksite: things falling on them and things piercing them from below. The core of any safety boot is built to defend against these threats.

The Role of the Safety Toe

A protective toe cap is the first line of defense against crushing or impact injuries from falling objects, rolling equipment, or compression. Its sole purpose is to prevent the bones of your forefoot from being crushed.

Steel vs. Alloy vs. Composite Toes

The material of the toe cap dictates its weight, conductivity, and profile.

- Steel toes are the traditional standard, offering maximum protection. They are also the heaviest option and will conduct heat and cold.

- Alloy toes, typically made of materials like aluminum or titanium, provide the same level of protection as steel but are significantly lighter.

- Composite toes are made from non-metal materials like carbon fiber, Kevlar, or plastic. They are the lightest option, do not conduct electricity or temperature, and won't set off metal detectors. However, they can sometimes be bulkier than their metal counterparts to achieve the same safety rating.

Underfoot Puncture Plates

A puncture-resistant plate is a layer integrated into the midsole that protects the bottom of your foot from sharp objects like nails, screws, or rebar. These can be made of steel for maximum rigidity or flexible composite fabrics for greater comfort.

Stability and Environmental Hazards

Beyond direct impacts, the work environment itself presents constant hazards. A boot's outsole and structural design are key to navigating these risks safely.

The Critical Importance of Slip-Resistant Outsoles

Slips, trips, and falls are among the most common causes of workplace injuries. A high-quality, slip-resistant outsole made from durable rubber or TPU with deep, channeled treads is non-negotiable for surfaces that may be wet, oily, or uneven.

Electrical Hazard (EH) Protection

If you work anywhere near live electrical circuits, you need EH-rated boots. These are constructed with non-conductive soles and heels that can protect you from accidental contact with electrical currents up to a specific voltage. This is a distinct feature that must be verified.

Why Ankle Support Matters

Hazardous worksites often involve unstable or rough terrain. A lace-up boot that extends over the ankle provides crucial mechanical support, helping to prevent sprains and twists. The ability to tighten the laces allows for a customized, secure fit that enhances this stability.

Understanding the Trade-offs and Certifications

Choosing the right boot involves balancing competing factors. Understanding these trade-offs and how to verify a boot's claims is essential.

The Balance Between Protection and Fatigue

There is a direct trade-off between the level of protection and the boot's weight. A boot with a steel toe and steel plate will offer immense protection but can contribute to fatigue over a long shift. A lighter composite boot may be far more comfortable for a worker who covers a lot of ground.

Decoding Safety Standards (ASTM F2413)

Do not rely on marketing terms alone. Look for a tag inside the boot that states it meets ASTM F2413 standards. This is the primary US certification for safety footwear. The tag will specify ratings for impact (I), compression (C), electrical hazard (EH), and puncture resistance (PR), confirming the boot's capabilities.

The Limits of "Waterproof" vs. "Water-Resistant"

"Water-resistant" means the material can shed light moisture for a short period. "Waterproof" implies the use of a membrane or sealed seams to keep your feet dry when submerged or in prolonged wet conditions. Choose based on your expected exposure.

Matching the Boot to Your Specific Hazard

Use your primary job function as the filter for selecting the right combination of features.

- If you work around heavy machinery or in construction: Prioritize the highest impact/compression rated safety toe (steel or alloy) and a puncture-resistant plate.

- If you are an electrician or work near live circuits: An EH-rated boot with a non-conductive composite toe is your non-negotiable starting point.

- If your site has constantly wet, oily, or uneven surfaces: A top-tier, slip-resistant outsole and strong ankle support are your primary concerns.

- If you work long shifts with extensive walking or climbing: Consider the weight trade-off of a lighter composite toe and a flexible puncture plate to reduce fatigue.

Ultimately, the right safety boot is the one that becomes an unnoticeable, reliable tool, allowing you to focus entirely on the task at hand.

Summary Table:

| Safety Feature | Key Purpose | Common Options |

|---|---|---|

| Protective Toe | Prevents crushing injuries from impacts | Steel, Alloy, Composite |

| Puncture Plate | Shields foot from sharp objects below | Steel, Composite Fabric |

| Slip-Resistant Outsole | Reduces slips on wet/oily surfaces | Durable Rubber, TPU |

| Electrical Hazard (EH) Rating | Protects against live electrical circuits | EH-rated construction |

| Ankle Support | Provides stability on uneven terrain | Lace-up design for secure fit |

Need a reliable source for certified safety boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality, ASTM F2413-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet the specific hazards of your work environment.

Contact us today to discuss your requirements and benefit from our expertise in durable, protective footwear solutions.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the signs that wildland firefighter boots need repair or replacement? A Guide to Critical Safety Checks

- What factors determine the durability of construction boots? A Guide to Long-Lasting Work Footwear

- Why are moc toe boots considered a versatile footwear choice? The Perfect Blend of Rugged Style & All-Day Comfort

- How should suede and nubuck leather work boots be cleaned? A Dry-Cleaning Guide to Preserve the Nap

- What are the key parts of a boot's anatomy? A Guide to Superior Support and Durability

- What is the primary function of a treadmill in the gait analysis of functional work shoes? Key to Data Standardization

- What are the key features of forestry boots? Essential Protection for Chainsaw Operators

- What should workers prioritize when selecting work boots for their industry? Match Boots to Hazards for Ultimate Safety