At its core, an electrical hazard (EH) rated mining boot works by isolating you from the ground. Its sole and heel are constructed from non-conductive, electrically insulating materials like rubber, which act as a barrier to stop the flow of electricity through your body in the event of accidental contact with a live electrical circuit.

The fundamental purpose of electrical hazard (EH) footwear is to break the electrical circuit. By using materials that resist the flow of electricity, the boot prevents the wearer's body from becoming the path between a live voltage source and the ground, thereby protecting against severe shock or electrocution.

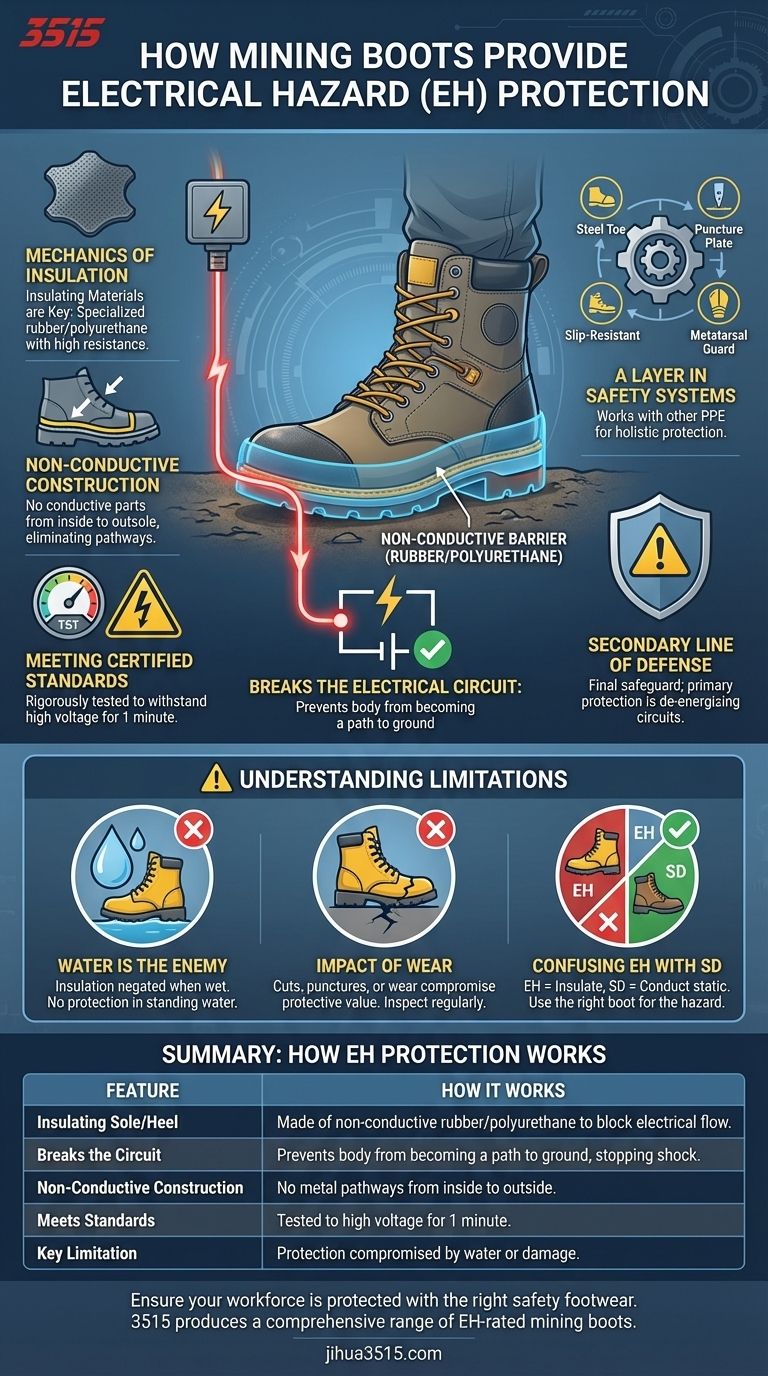

The Mechanics of Electrical Insulation

The effectiveness of EH protection hinges on simple but critical principles of electrical engineering. A boot is designed to be a poor conductor, preventing you from completing a dangerous circuit.

Insulating Materials are Key

The primary protective feature is the material used for the outsole and heel. These components are made from compounds, typically specialized rubber or polyurethane, that are highly effective electrical insulators. They offer immense resistance to the flow of electrical current.

Breaking the Electrical Circuit

For a dangerous electric shock to occur, your body must become part of a complete circuit between a power source and the ground. EH-rated boots act as a powerful insulator at the point of contact with the ground, effectively breaking that circuit and keeping the current from passing through you.

Non-Conductive Construction

True EH-rated footwear is designed to have no conductive parts, such as metal, passing from the inside of the boot to the outsole. This ensures there are no unintended pathways for electricity to bypass the insulating sole.

Meeting Certified Standards

These boots are not merely made of rubber; they are rigorously tested. To earn an EH rating, footwear must withstand the application of a very high voltage for at least one minute without allowing a dangerous amount of current to flow through.

The Role of EH Boots in Mining Safety

While crucial, EH protection is one piece of a comprehensive safety system. It's essential to understand its place among other protective features required in hazardous environments.

A Layer in a System of Safety

Mining boots are multi-functional pieces of personal protective equipment (PPE). EH protection works alongside other critical features like steel or composite safety toes, puncture-resistant plates, slip-resistant soles, and metatarsal guards to provide holistic protection.

A Secondary Line of Defense

It is critical to understand that EH boots are considered a secondary source of protection. The primary methods for preventing electrical injury always involve de-energizing circuits, proper lock-out/tag-out procedures, and other safe work practices. The boots are a final safeguard for accidental or unforeseen contact.

Understanding the Limitations and Pitfalls

Trusting your equipment requires knowing its limits. The insulating properties of EH boots can be compromised under certain conditions, which every wearer must recognize.

Water is the Enemy

The most significant limitation is water. The insulating properties of the boot's sole are dramatically reduced or completely negated when wet. EH-rated boots offer no reliable protection in standing water or excessively damp environments.

The Impact of Wear and Damage

Any physical damage to the sole compromises its protective value. Cuts, punctures from sharp objects, or excessive wear can create a path for electricity to travel through the sole, rendering the EH rating ineffective. Regular inspection of your boots is non-negotiable.

Confusing EH with Static Dissipating (SD)

Do not confuse Electrical Hazard (EH) boots with Static Dissipating (SD) or Conductive footwear. They serve opposite functions.

- EH boots insulate you to prevent current from flowing through you.

- SD boots conduct a small, controlled amount of static electricity to the ground to prevent static buildup that could damage sensitive electronics or ignite flammable materials. Wearing the wrong type of boot for your specific environment is a critical safety failure.

Making the Right Choice for Your Environment

Selecting the correct footwear depends entirely on a clear assessment of the primary hazards you face on the job site.

- If your primary focus is protection from live circuits: You must select boots specifically designated with an Electrical Hazard (EH) rating.

- If your primary focus is preventing static discharge: In environments with sensitive electronics or flammable vapors, you must use Static Dissipating (SD) or Conductive footwear.

- If your primary focus is all-around physical protection: Ensure your boot combines the necessary EH rating with other vital features like impact resistance, puncture plates, and adequate ankle support for the terrain.

Ultimately, understanding how your equipment functions is the first step toward ensuring your own safety in a hazardous workplace.

Summary Table:

| Feature | How It Provides EH Protection |

|---|---|

| Insulating Sole/Heel | Made of non-conductive rubber/polyurethane to block electrical flow. |

| Breaks the Circuit | Prevents the body from becoming a path to ground, stopping electric shock. |

| Non-Conductive Construction | No metal parts from inside to outside, eliminating current pathways. |

| Meets Certified Standards | Rigorously tested to withstand high voltage for one minute. |

| Key Limitation | Protection is compromised if soles are wet, cut, or excessively worn. |

Ensure your workforce is protected with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of EH-rated mining boots for distributors, brand owners, and bulk clients. Our boots combine certified electrical hazard protection with essential features like steel toes and puncture-resistant plates. Contact us today to discuss your specific needs and get a quote for durable, reliable safety footwear.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- How do breathable linings in PVC work boots improve comfort? Master Moisture & Temperature Control

- What are the main characteristics of PVC for work boots? Unbeatable Waterproofing & Chemical Resistance

- How do the heels differ between cowboy boots and Western work boots? Choose the Right Heel for Your Job

- Why is inspecting footbeds and boot fitment necessary? Prevent Pain and Ensure Workplace Safety

- What are the six key qualities to look for in a good work-safe boot? Find the Perfect Fit for Your Job

- What are the key advantages of cowboy boots? Discover Unmatched Durability & Style

- Are heavy duty work boots suitable for extreme weather? Key Features for Ultimate Protection

- How did moc toe boots transition from workwear to casual wear? Discover the Style Evolution