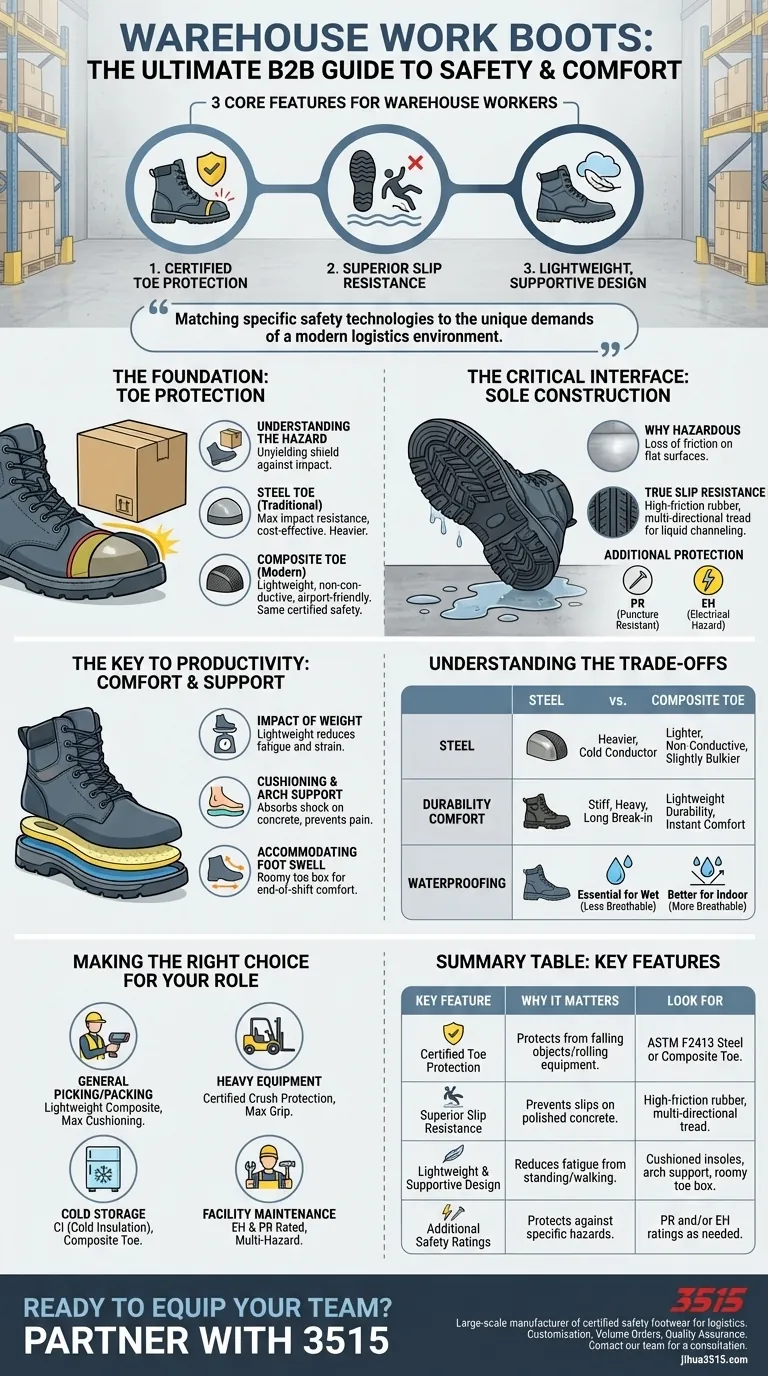

For warehouse workers, the ideal work boot prioritizes three core features: certified toe protection, superior slip resistance for concrete floors, and a lightweight, supportive design for all-day comfort. These elements work in concert to protect you from the most common workplace hazards—impact from falling objects and slips on slick surfaces—while mitigating the fatigue that comes from spending hours on your feet.

Choosing the right warehouse boot is not about finding the heaviest or toughest boot available. It's about matching specific safety technologies to the unique demands of a modern logistics environment: hard, flat surfaces, constant movement, and the risk of crush or impact injuries.

The Foundation: Toe Protection

The most immediate and obvious hazard in a warehouse is the risk of something heavy falling on your foot. Your boot's first job is to provide an unyielding shield against that impact.

Understanding the Hazard

Warehouse environments are filled with heavy objects, from dropped boxes to rolling pallet jacks. Certified safety toes are a non-negotiable feature designed to withstand significant force and compression.

Steel Toe: The Traditional Standard

Steel toes have long been the industry benchmark for protection. They offer maximum resistance to impact and crushing forces and are often the most cost-effective option.

Composite Toe: The Modern Alternative

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. They provide the same level of certified safety as steel but are significantly lighter, do not conduct cold or heat, and won't set off metal detectors.

The Critical Interface: Sole Construction

A warehouse floor is a unique surface. It's typically hard, flat, and can become incredibly slick from dust, spills, or moisture. The sole of your boot is the critical connection between you and that floor.

Why Warehouse Floors Are Hazardous

Unlike uneven outdoor terrain that requires deep lugs for grip, a polished concrete floor demands a different approach. The danger comes from a loss of friction across a large, flat surface.

Defining True Slip Resistance

Look for soles made of high-friction rubber with a tread pattern of small, multi-directional grooves. This design works to channel away liquids and maximize the surface area in contact with the floor, preventing slips.

Puncture and Electrical Hazard Protection

If your work involves maintenance or areas with sharp debris like nails or screws, a puncture-resistant (PR) plate in the sole is essential. For those working near electrical equipment, boots with an Electrical Hazard (EH) rating provide a vital secondary layer of protection against shock.

The Key to Productivity: Comfort and Support

Safety features protect you from accidents, but comfort and support protect you from the daily strain of the job. Fatigue is a major contributor to workplace injuries and reduced productivity.

The Impact of Weight

Every ounce on your feet adds up over thousands of steps a day. A lightweight boot, often achieved with a composite toe and modern materials, directly reduces fatigue and strain on your legs and back.

Cushioning and Arch Support

Standing and walking on concrete for an entire shift is punishing. Look for boots with superior cushioning in the insole and midsole to absorb shock. Proper arch support prevents foot pain and conditions like plantar fasciitis.

Accommodating Foot Swell

Feet naturally swell throughout the workday. A boot with a slightly roomier toe box ensures that your feet remain comfortable and are not constricted by the end of your shift.

Understanding the Trade-offs

Choosing the perfect boot involves balancing competing factors. Being aware of these trade-offs allows you to make a more informed decision.

Steel vs. Composite Toe: Beyond Safety

While both offer certified protection, steel is often heavier and conducts temperature, making it feel cold in refrigerated environments. Composite toes are lighter and don't conduct temperature, but can sometimes result in a slightly bulkier boot profile.

Durability vs. Comfort

The most rugged, durable materials can sometimes be stiff and heavy, requiring a longer break-in period and potentially causing more fatigue. Modern lightweight materials often provide excellent durability without the associated weight penalty.

Waterproofing: A Necessary Feature or Overkill?

A truly waterproof (WR) boot is essential for wet environments but can reduce breathability, leading to sweaty, uncomfortable feet in a dry, climate-controlled warehouse. A water-resistant (WRU) upper is often a better compromise for most indoor roles.

Making the Right Choice for Your Role

Select your boot based on the specific demands of your daily tasks.

- If your primary focus is general picking and packing: Prioritize a lightweight composite toe boot with excellent cushioning to minimize fatigue during constant movement.

- If you operate heavy equipment like forklifts or pallet jacks: Ensure you have certified crush protection (steel or composite toe) and a sole that provides maximum grip on smooth concrete.

- If you work in a cold storage or refrigerated warehouse: You must select boots with a CI (Cold Insulation) rating and a composite toe, as steel will transfer the cold directly to your feet.

- If your role involves facility maintenance: Choose boots with both an EH (Electrical Hazard) rating and a PR (Puncture Resistant) sole to protect against a wider range of hazards.

Investing in the right boot is a direct investment in your daily safety, comfort, and long-term well-being.

Summary Table:

| Key Feature | Why It Matters for Warehouse Work | Look For |

|---|---|---|

| Certified Toe Protection | Protects feet from heavy falling objects and rolling equipment. | ASTM F2413 certified Steel Toe or lighter Composite Toe. |

| Superior Slip Resistance | Prevents slips and falls on slick, polished concrete floors. | High-friction rubber soles with multi-directional tread patterns. |

| Lightweight & Supportive Design | Reduces fatigue from standing and walking all day. | Cushioned insoles, arch support, and a roomy toe box for foot swell. |

| Additional Safety Ratings | Protects against specific hazards like sharp objects or electrical shock. | PR (Puncture Resistant) and/or EH (Electrical Hazard) ratings as needed. |

Ready to equip your team with the perfect warehouse work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear designed for the demands of logistics and warehousing. We deliver the durability, comfort, and protection your distributors, brand owners, and bulk clients require.

Let's discuss your specific needs:

- Customization: Tailor boots for cold storage, heavy equipment operation, or general picking.

- Volume Orders: Reliable supply and competitive pricing for bulk clients.

- Quality Assurance: All products meet rigorous safety standards.

Contact our team today for a consultation and discover how 3515 can be your trusted partner in workforce safety.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- Why do landscapers need steel-toe boots? Essential Protection for a Hazardous Job

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- What is the purpose of metatarsal protection in work boots? Essential Safety for Your Instep

- What are the main types of safety toe boots? Choose the Right Protection for Your Job

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job