In Goodyear welted shoes, cork serves a critical threefold purpose. It is used to fill the cavity between the insole and the outsole, where it acts as a natural cushion, provides excellent thermal insulation, and most importantly, gradually molds to the shape of your foot for a truly customized fit over time.

The use of cork is not merely a filler material; it is a fundamental component that allows the shoe to personalize itself to the wearer, creating a unique and supportive footbed that improves with age.

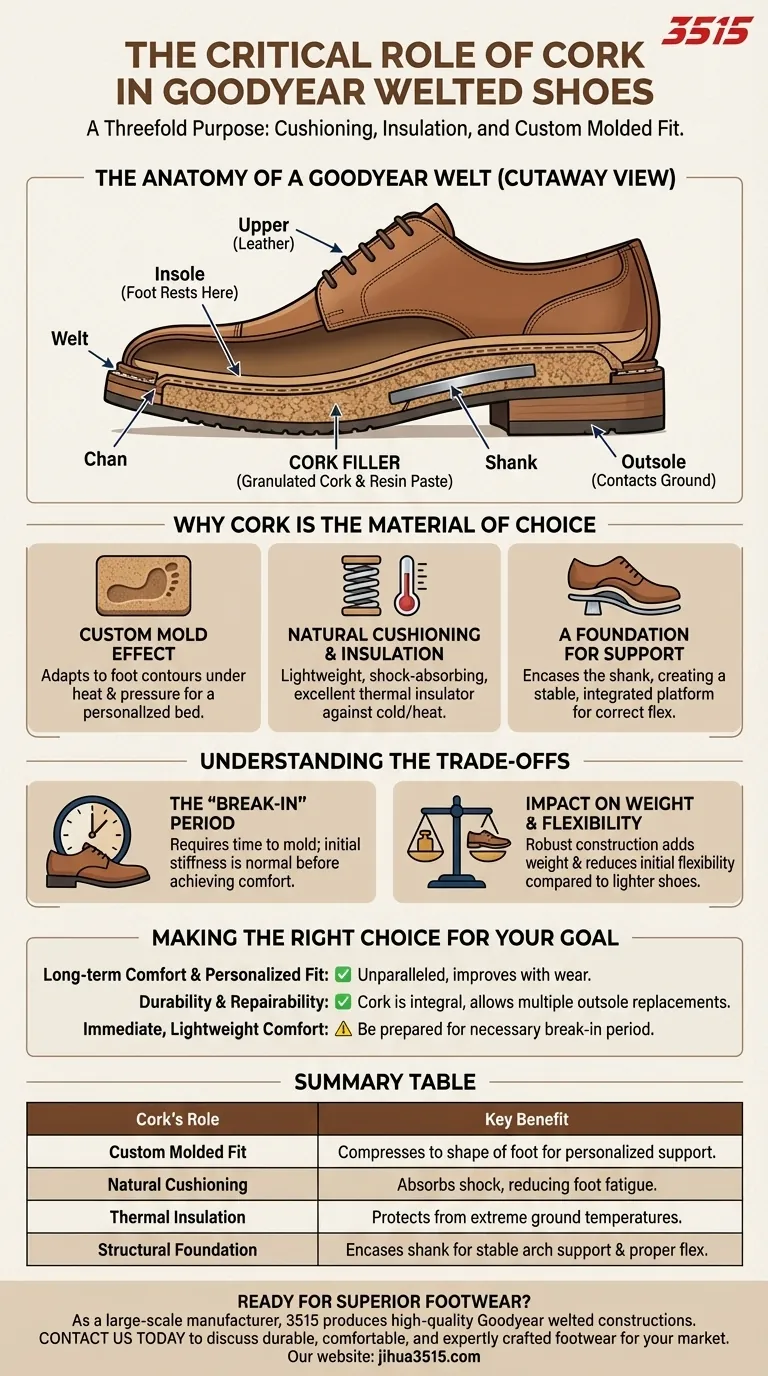

The Anatomy of a Goodyear Welt

To understand cork's role, you must first understand the structure it inhabits. The Goodyear welting process is renowned for its durability and repairability.

Creating the Cavity

The process begins by stitching a strip of leather, known as the welt, around the perimeter of the shoe's insole and upper. This welt creates a distinct boundary, forming a shallow cavity between the insole (where your foot rests) and the outsole (which contacts the ground).

Filling the Void

This cavity cannot be left empty, as it would create an unstable and uncomfortable platform. It is filled with a layer of granulated cork, often mixed with a resin to create a spreadable paste. This cork bed is what separates your foot from the final outsole.

Why Cork is the Material of Choice

While other materials could fill this space, cork is used for its unique combination of properties that are perfectly suited for high-quality footwear.

The "Custom Mold" Effect

The most celebrated benefit of the cork filler is its ability to adapt. Under the heat and pressure of your body weight during wear, the cork bed compresses and conforms to the precise contours of your foot. This creates a personalized footbed, offering support exactly where you need it.

Natural Cushioning and Insulation

Cork is naturally lightweight and porous, giving it excellent shock-absorbing qualities. This provides a comfortable cushion for every step, reducing fatigue. Furthermore, these same properties make it a superb thermal insulator, protecting your feet from the cold ground in winter and excessive heat in summer.

A Foundation for Support

The cork bed works in tandem with other structural elements. It encases the shank—a supportive piece of steel or leather placed under the arch—creating a stable, integrated platform that ensures the shoe flexes correctly at the ball of the foot.

Understanding the Trade-offs

The benefits of a cork-filled Goodyear welt are significant, but they come with certain considerations that are important to understand.

The "Break-in" Period

The very process of the cork molding to your foot requires time. This is why new Goodyear welted shoes often feel stiff and rigid out of the box. The shoe requires a "break-in" period of several wears before the cork footbed personalizes and the shoe achieves its renowned comfort.

Impact on Weight and Flexibility

The robust, multi-layered construction of a Goodyear welt, including the welt, cork filling, and thick soles, inherently adds weight and reduces initial flexibility compared to lighter, cemented shoe constructions. This is the trade-off for superior durability and a supportive fit.

Making the Right Choice for Your Goal

Understanding the role of cork helps you align your footwear choice with your priorities.

- If your primary focus is long-term comfort and a personalized fit: The cork footbed is a defining feature that delivers unparalleled, customized support that improves the more you wear the shoe.

- If your primary focus is durability and repairability: Cork is an integral part of the Goodyear welt system, which allows the outsole to be replaced multiple times without affecting the integrity of the upper or the molded footbed.

- If your primary focus is immediate, lightweight comfort: Be prepared for the necessary break-in period, as the initial stiffness is a prerequisite for the long-term benefits of the molded cork.

Ultimately, the cork filler is a key reason why Goodyear welted shoes are considered an investment in footwear that truly becomes your own.

Summary Table:

| Cork's Role | Key Benefit |

|---|---|

| Custom Molded Fit | Compresses to the shape of your foot over time for personalized support. |

| Natural Cushioning | Absorbs shock with every step, reducing foot fatigue. |

| Thermal Insulation | Protects feet from extreme ground temperatures. |

| Structural Foundation | Encases the shank for stable arch support and proper flex. |

Ready to experience the superior comfort and durability of footwear built with these principles?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including high-quality Goodyear welted constructions.

Contact us today to discuss how we can bring durable, comfortable, and expertly crafted footwear to your market.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- What makes Wholecut shoes unique? The Ultimate Guide to Sleek, Single-Piece Craftsmanship

- What is the six-step process for waterproofing leather shoes? A Definitive Guide to Lasting Protection

- How do Derby shoes differ from Oxford shoes? A Guide to Formality, Fit & Style

- How does the double stitching in Goodyear Welted shoes contribute to their durability? Unlock Decades of Wear

- How should outsole stitching (double thread lock-stitch 301) be performed for durability? Master the 3-Step Process

- How should Goodyear welted shoes be protected from environmental damage? Master the Defense & Recovery Cycle

- What are the characteristics of longwing shoes and when should they be worn? A Guide to This Classic Brogue

- What are the recommended colors for Jodhpur ankle boots? Master Your Style with Brown or Black