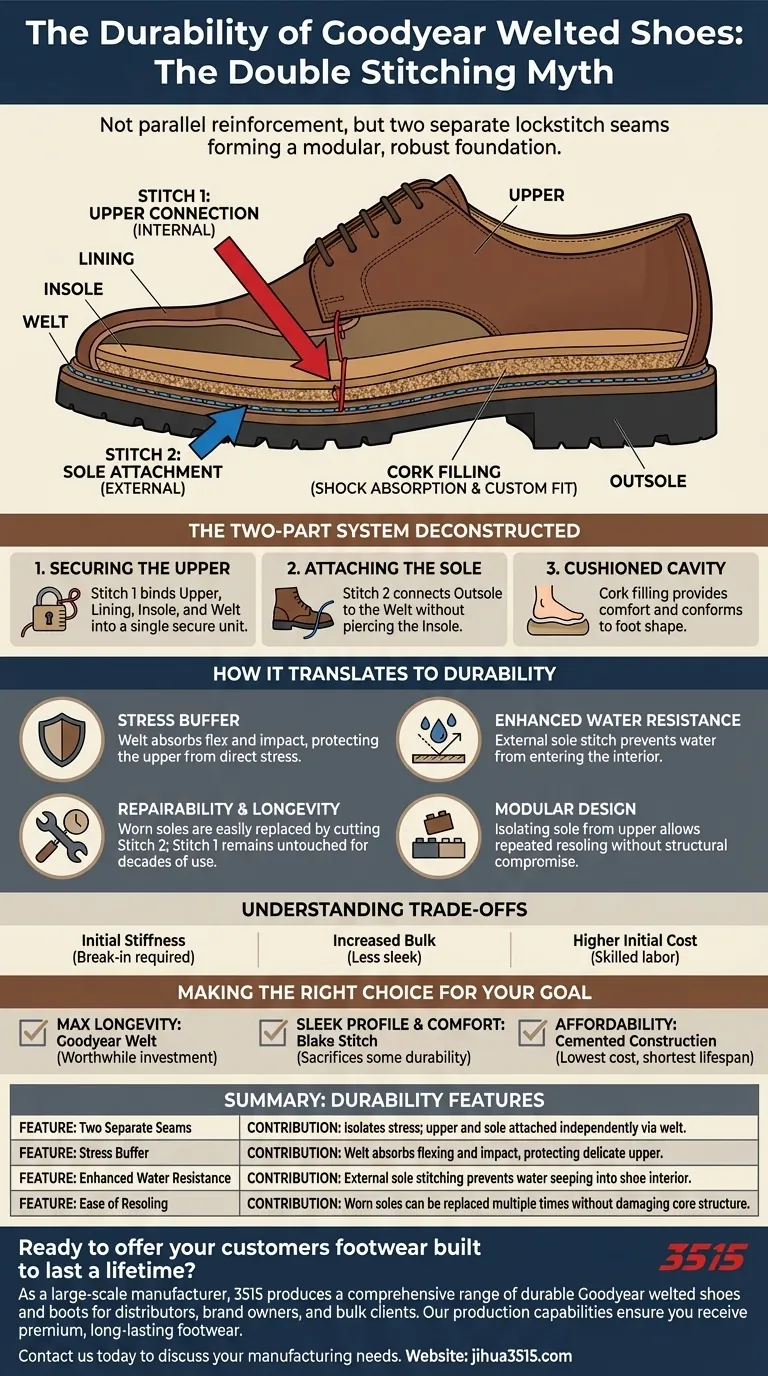

The term "double stitching" in Goodyear welted shoes is slightly misleading. It doesn’t refer to two parallel stitches for reinforcement, but rather to two entirely separate lockstitch seams that form the shoe's structural foundation. The first stitch connects the shoe's upper to the welt—a durable strip of leather—while the second, independent stitch attaches the outsole to that same welt, creating a uniquely robust and repairable footwear platform.

The true genius of the Goodyear welt lies not just in its strength, but in its modular design. By isolating the sole from the upper with a separate "welt," it creates a shoe that is exceptionally durable and can be resoled repeatedly without compromising the shoe's core structure.

Deconstructing the Goodyear Welt: A Two-Part System

To understand the source of its durability, you must visualize the Goodyear welt not as a single feature but as an integrated construction method. It creates a secure frame around the shoe that isolates key components from stress.

The First Connection: Securing the Upper

The first structural seam is entirely internal. It uses a strong lockstitch to bind four key components together: the leather upper, the lining, the insole, and the welt. This stitch creates a single, incredibly secure unit that forms the main body of the shoe.

The Second Connection: Attaching the Sole

The second seam is the one you can often see running along the outside edge of the sole. This stitch passes through the welt and attaches the outsole. Crucially, this stitch never penetrates the insole or the interior of the shoe.

The Result: A Cushioned, Secure Cavity

This two-part construction method creates a cavity between the insole and the outsole. This space is filled with granulated cork, which provides excellent shock absorption and, over time, molds to the unique shape of your foot for a custom-like fit.

How This System Translates to Durability

The separation of these two core seams is what gives the Goodyear welt its legendary reputation for longevity and strength. Each aspect of the design contributes to a shoe that can withstand years of demanding use.

A Buffer Against Stress

The welt acts as a robust intermediary layer or "buffer" between the upper and the sole. All the flexing stress and impact from walking is transferred to the welt and the sole stitching, not directly to the delicate leather of the upper.

Enhanced Water Resistance

Because the second stitch attaching the sole is external and doesn't pierce the insole, it creates a much more water-resistant seal compared to other methods where the stitch goes directly into the shoe's interior.

The Foundation for Longevity: Resoling

This is the single most important advantage. When the sole wears out, a cobbler simply cuts the second, external stitch and attaches a new sole to the existing welt. The original, foundational stitch holding the upper remains completely untouched. This allows the shoes to be resoled multiple times, dramatically extending their functional lifespan for decades with proper care.

Understanding the Trade-offs

No construction method is perfect for every situation. The robustness of a Goodyear welt comes with inherent trade-offs that are important to acknowledge.

Initial Stiffness

The multiple layers and durable materials result in a shoe that is initially quite stiff. Goodyear welted shoes require a significant "break-in" period for the leather and cork to soften and conform to your foot.

Increased Bulk

The extra welt layer and external stitching add a noticeable amount of bulk and weight to the shoe's profile. This construction is less sleek and flexible than alternatives like a Blake stitch.

Higher Initial Cost

The Goodyear welting process is more complex and labor-intensive than simpler methods like cementing (gluing) soles on. This skilled labor translates directly into a higher upfront purchase price.

Making the Right Choice for Your Goal

Deciding if a Goodyear welt is right for you depends entirely on your priorities for your footwear.

- If your primary focus is maximum longevity and repairability: The Goodyear welt is the undisputed industry standard and a worthwhile long-term investment.

- If your primary focus is a sleek, lightweight profile and immediate comfort: You may prefer a Blake-stitched shoe, but you sacrifice some water resistance and ease of resoling.

- If your primary focus is affordability for occasional wear: A standard cemented construction offers the lowest price point but is typically not repairable and has the shortest lifespan.

Understanding the mechanics of a Goodyear welt transforms your purchase from a simple transaction into a long-term investment in quality.

Summary Table:

| Feature | Contribution to Durability |

|---|---|

| Two Separate Seams | Isolates stress; upper and sole are attached independently via a leather welt. |

| Stress Buffer | The welt absorbs flexing and impact, protecting the delicate leather upper. |

| Enhanced Water Resistance | External sole stitching prevents water from seeping into the shoe's interior. |

| Ease of Resoling | Worn soles can be replaced multiple times without damaging the shoe's core structure. |

Ready to offer your customers footwear built to last a lifetime?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you receive premium, long-lasting footwear that your customers can rely on for years.

Contact us today to discuss your manufacturing needs and explore our full catalog.

Visual Guide

Related Products

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

People Also Ask

- How does the Goodyear Welted construction allow for sole replacement without damaging the upper? Discover the Secret to Long-Lasting Footwear

- How much does resoling Goodyear welted shoes typically cost? A Guide to Cost vs. Value

- Why is it necessary to establish a scientific Reorder Point (ROP) for the inventory management of dress shoes?

- What are the main differences between formal and casual dress shoes? A Guide to Choosing the Right Shoe

- How should dress shoes be properly cared for? A Step-by-Step Guide to Extend Their Lifespan

- What are the features of Jodhpur boots? A Guide to the Iconic Ankle Strap Boot

- How does the Goodyear welt process differ from traditional methods? Unlock Superior Durability & Repairability

- What is the origin of the name 'chukka boots'? From Polo Fields to Global Style