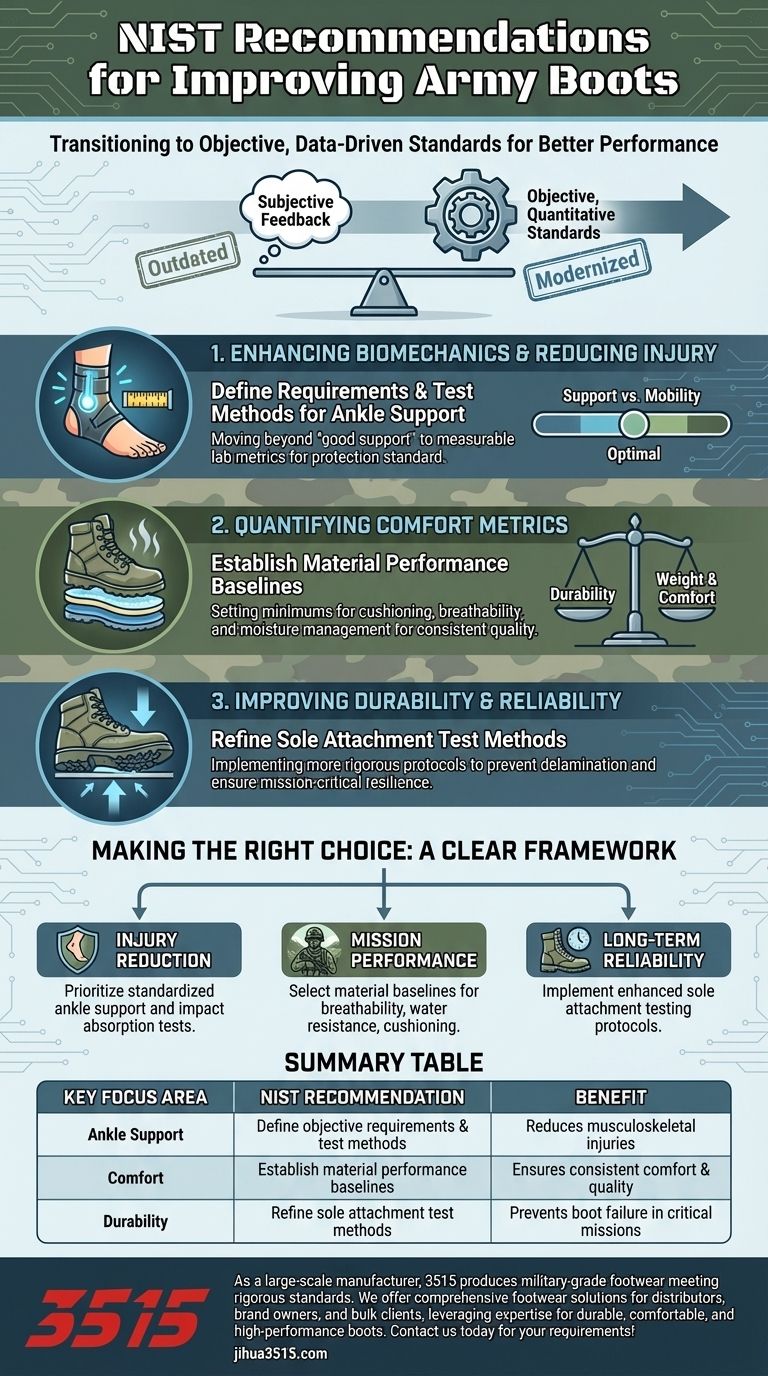

To improve Army boots, the National Institute of Standards and Technology (NIST) provided a set of 13 recommendations focused on creating objective, data-driven standards. These suggestions specifically address defining requirements for ankle support, establishing material performance baselines for comfort, and refining test methods for sole attachment to improve overall boot performance.

The core shift recommended by NIST is moving away from subjective soldier feedback and toward a foundation of quantitative, repeatable test methods to guarantee better biomechanics, comfort, and durability in military footwear.

The Push for Objective Footwear Standards

For years, military footwear development has relied heavily on qualitative feedback. While valuable, this approach can be inconsistent and slow. NIST's recommendations aim to introduce a more scientific, engineering-based framework to solve persistent challenges.

Enhancing Biomechanics and Reducing Injury

A primary goal is to lower the rate of musculoskeletal injuries among soldiers.

NIST emphasized the need to clearly define requirements and test methods for ankle support. This moves beyond a general desire for "good support" and into measurable metrics that can be tested in a lab, ensuring all boots meet a specific protective standard.

Quantifying the Metrics of Comfort

Comfort is notoriously subjective, but its components can be measured.

The recommendations call for setting material performance baselines for factors contributing to comfort, such as cushioning, breathability, and moisture management. By establishing these minimums, the Army can ensure a consistent level of quality across all approved footwear.

Improving Durability and Reliability

Boot failure in the field is a critical issue that directly impacts mission readiness.

To address this, NIST focused on improving sole attachment test methods. A common failure point is the delamination of the sole from the upper, and creating a more rigorous, realistic test protocol ensures that boots are built to withstand mission-critical stress.

Understanding the Trade-offs

Creating the "perfect" boot involves balancing competing characteristics. The NIST recommendations help quantify these trade-offs rather than leaving them to chance.

Support vs. Mobility

Increased ankle support, while crucial for preventing sprains on rough terrain, can sometimes limit a soldier's mobility and flexibility.

Standardized testing allows designers to find the optimal balance, providing the necessary protection without unduly hindering movement.

Durability vs. Weight and Comfort

Highly durable materials, especially in the sole, can increase weight and reduce flexibility, impacting comfort and increasing fatigue.

By setting performance baselines for both durability and comfort-related materials, manufacturers can innovate toward solutions that meet both requirements without unacceptable compromises.

Making the Right Choice for Your Goal

These recommendations provide a clear framework for future military footwear procurement and design.

- If your primary focus is injury reduction: Prioritize the adoption of standardized, biomechanical tests for ankle support and impact absorption.

- If your primary focus is mission-specific performance: Use the material baselines to select footwear with the right balance of breathability, water resistance, and cushioning for a given operational environment.

- If your primary focus is long-term reliability: Implement the enhanced sole attachment testing protocols to significantly reduce the risk of boot failure in the field.

Ultimately, these standards empower the military to procure and field footwear that is demonstrably safer, more comfortable, and more reliable.

Summary Table:

| Key Focus Area | NIST Recommendation | Benefit |

|---|---|---|

| Ankle Support | Define objective requirements and test methods | Reduces musculoskeletal injuries |

| Comfort | Establish material performance baselines (cushioning, breathability) | Ensures consistent comfort and quality |

| Durability | Refine sole attachment test methods | Prevents boot failure in critical missions |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including military-grade footwear designed to meet rigorous standards like those recommended by NIST. Let us help you develop durable, comfortable, and high-performance boots tailored to your specific needs. Contact us today to discuss how we can support your footwear requirements with our expertise and manufacturing excellence!

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

People Also Ask

- What boots does the army use? The Ultimate Guide to Tactical Footwear

- What is the timeline for finalizing the jungle boot design? A Detailed Look at the 2018-2019 Schedule

- What are the key features of Army combat boots? Essential Design for Maximum Durability & Protection

- Why is polyurethane used in army combat boots? Superior Durability & Lightweight Support

- How does the new jungle boot improve upon the M1966 Vietnam-era jungle boot? A Modern Evolution in Soldier Comfort & Protection

- What makes navy blue desert boots unique? A Modern Twist on a Timeless Classic

- Does the army still use jump boots? From Battlefield to Ceremonial Symbol

- What are some examples of desert boots with leather uppers? Explore Versatile & Durable Styles