When it comes to mission-critical equipment, polyurethane is used for the soles and heels of army combat boots because it offers an unparalleled combination of shock absorption, durability, and light weight. This material provides crucial support to the heel and arches, directly reducing the physical impact on a soldier's feet and joints during high-stress activities like long marches or runs.

The selection of polyurethane for combat boots is not about a single feature, but its engineered balance of properties. It delivers the shock-absorbing cushion of rubber and the rugged toughness of a hard plastic, all within a lightweight package essential for reducing soldier fatigue and preventing injury.

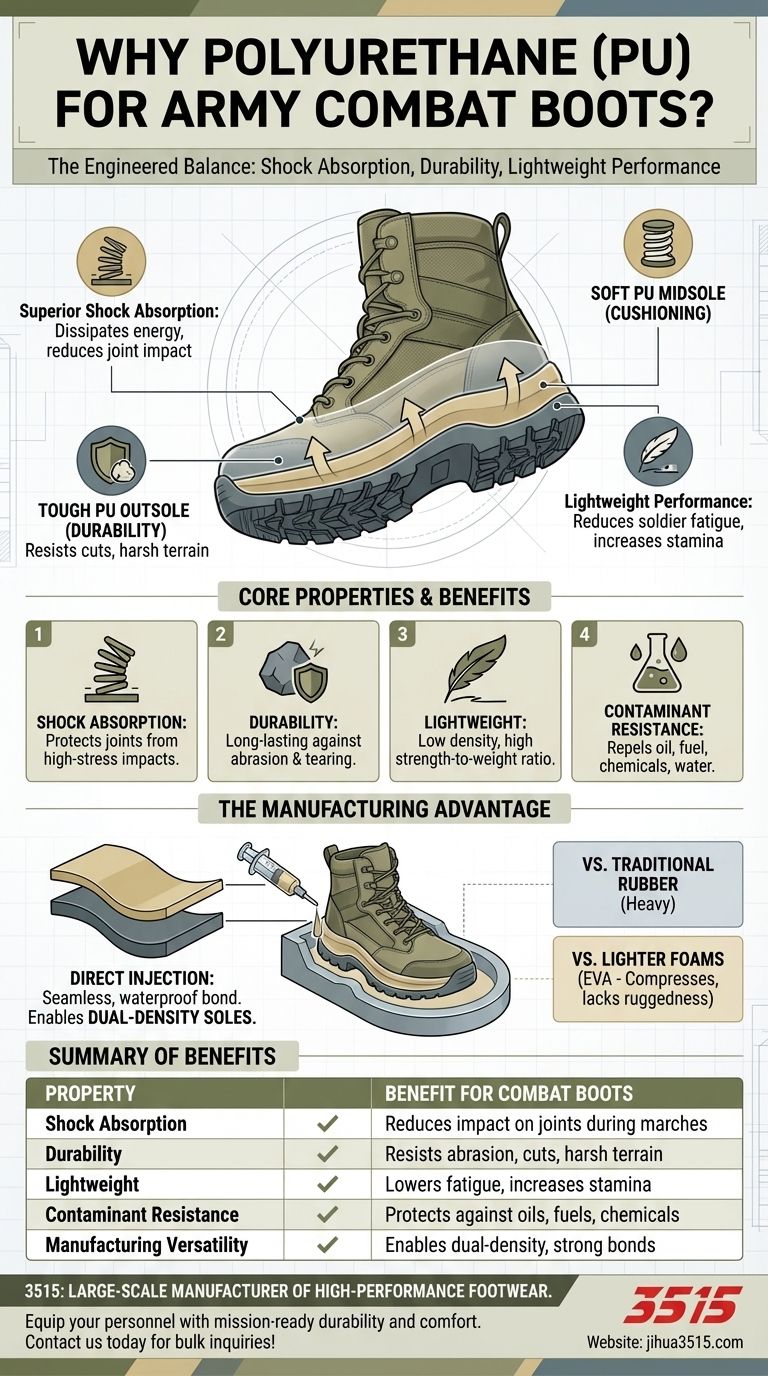

The Core Properties of Polyurethane in Boot Soles

To understand why polyurethane (PU) is the standard, we must look at the specific performance demands of a combat environment. The material must protect the user without becoming a source of fatigue or failure.

Superior Shock Absorption

A soldier's body endures immense stress from carrying heavy loads over unforgiving terrain.

The molecular structure of polyurethane is exceptionally effective at absorbing and dissipating the energy from each footstep. This significantly reduces the shock transmitted to the feet, ankles, knees, and spine.

Exceptional Durability and Abrasion Resistance

Combat boots are subjected to extreme wear from rocks, rubble, asphalt, and sand.

PU is highly resistant to abrasion, cuts, and tearing. This ensures the sole maintains its structural integrity, protecting the foot and extending the service life of the boot far beyond that of simpler materials.

Lightweight Performance

When a soldier is carrying pounds of gear, every ounce matters. Reducing the weight on their feet is one of the most effective ways to combat fatigue.

Polyurethane provides its strength and cushioning at a much lower density than traditional solid rubber. This weight savings translates directly to increased stamina and operational effectiveness.

Resistance to Contaminants

The modern battlefield can expose footwear to a variety of damaging substances.

Polyurethane is inherently resistant to water, oils, fuels, and many common chemicals. This prevents the sole from degrading, swelling, or losing its bond with the rest of the boot, ensuring reliable performance across diverse environments.

Understanding the Trade-offs

While polyurethane is a superior material for this application, no choice is without its considerations. Acknowledging these trade-offs provides a complete picture of its role.

The Problem with Traditional Rubber

Thick, solid rubber can offer good durability but comes with a significant weight penalty. It is also often less effective at cushioning than a properly engineered PU midsole and can be more susceptible to degradation from UV light and certain chemicals.

The Limitation of Lighter Foams

Materials like EVA (ethylene-vinyl acetate), common in running shoes, are extremely lightweight but lack the ruggedness for military use. They can "pack out" or permanently compress over time, losing their cushioning, and are easily cut or punctured.

The Manufacturing Advantage

One of polyurethane's greatest strengths is its versatility in manufacturing. Through a process called direct injection, a liquid PU mixture can be molded directly onto the boot's upper, creating a seamless, waterproof, and incredibly strong bond that is nearly impossible to separate. This also allows for the creation of dual-density soles, with a softer PU in the midsole for cushioning and a tougher PU in the outsole for durability.

Making the Right Choice for Your Goal

Understanding the "why" behind this material choice helps clarify its benefits for any high-performance footwear.

- If your primary focus is maximum durability and protection: Polyurethane's abrasion, tear, and chemical resistance make it the definitive choice for any harsh or unpredictable environment.

- If your primary focus is reducing fatigue and injury risk: The combination of superior shock absorption and low weight is critical for minimizing physical stress during prolonged activity.

- If your primary focus is long-term value: The exceptional lifespan of a PU sole reduces the need for frequent replacement, making it a highly cost-effective solution for demanding users.

Ultimately, polyurethane is the material of choice because it ensures a soldier's footwear is a reliable asset, not a liability, in the most demanding conditions imaginable.

Summary Table:

| Property | Benefit for Combat Boots |

|---|---|

| Shock Absorption | Reduces impact on joints during marches and runs |

| Durability | Resists abrasion, cuts, and harsh terrain |

| Lightweight | Lowers fatigue and increases soldier stamina |

| Contaminant Resistance | Protects against oils, fuels, and chemicals |

| Manufacturing Versatility | Enables dual-density soles and strong, seamless bonds |

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities include combat boots with advanced polyurethane soles, ensuring durability, lightweight comfort, and mission-ready reliability. Let us help you equip your personnel with footwear that stands up to the toughest conditions—contact us today to discuss your needs!

Visual Guide

Related Products

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

People Also Ask

- Will all soldiers be issued the new jungle boots? A Guide to the Army's Phased Rollout

- How have army boots evolved over time? From Roman Sandals to Modern Performance Gear

- What is excorporation, and how does it relate to combat boots? Understanding Cultural Rebellion

- What are jungle boots and what environments are they suited for? Master Hot, Wet Terrain

- How do army boots differ from regular hiking boots? Durability vs. Comfort Explained

- What additional features enhance the durability of army combat boots? A Guide to Superior Military Footwear

- How did the desert boot design become popular after World War II? A Tale of Style & Counter-Culture

- How does a four-legged conversion bracket attachment reduce injury rates? Advanced Blast Protection & Mitigation