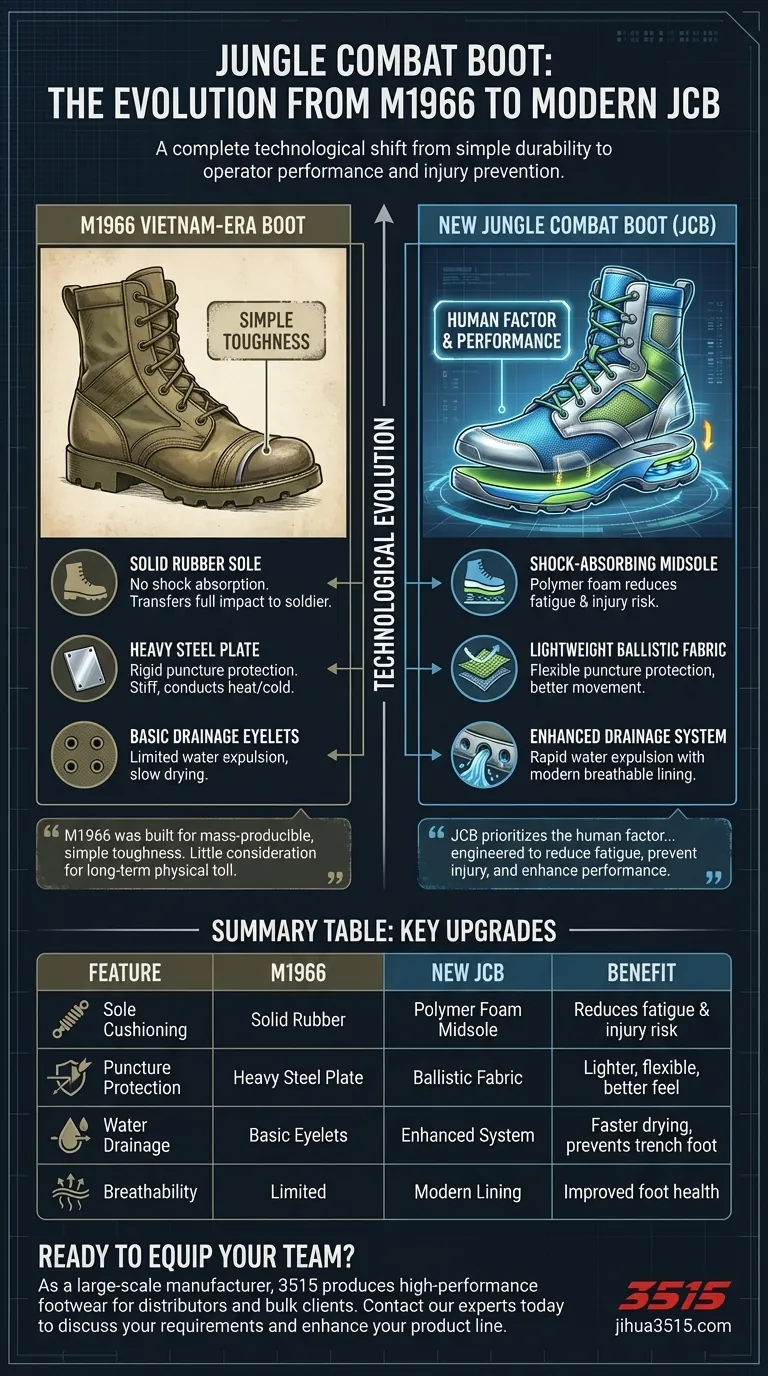

In short, the new Jungle Combat Boot (JCB) is a complete technological evolution of the M1966 Vietnam-era model. While it retains the classic mud-shedding outsole, the JCB incorporates modern materials and construction methods to dramatically improve shock absorption, puncture protection, and overall soldier comfort. It replaces outdated components like solid rubber and steel with advanced polymers and ballistic fabrics.

The core difference is a fundamental shift in design philosophy. The M1966 was built for simple durability, while the new JCB is engineered to reduce fatigue, prevent injury, and enhance the operator's performance through modern ergonomics and materials science.

The Foundation: Rethinking the Sole Assembly

The most significant changes in the JCB are found in its sole, which was completely re-engineered from the ground up to address the primary failings of the legacy boot.

From Solid Rubber to Shock Absorption

The old M1966 featured a direct-molded, solid rubber sole. While durable, it offered virtually no cushioning, transferring the full impact of every step directly to the soldier's feet, knees, and back.

The JCB introduces a modern, shock-absorbing midsole. This layer, made of a cushioned polymer foam, is integrated using a direct attach construction, creating a powerful bond between the sole and the upper. This single change drastically reduces fatigue and the risk of stress-related injuries.

Modernizing Puncture Protection

The M1966 relied on a heavy, rigid steel plate in the sole for puncture protection from stakes and sharp objects. This made the boot stiff, heavy, and conducted heat and cold.

The new boot replaces this with a puncture-resistant ballistic fabric layer. This modern material offers comparable protection while being significantly lighter and more flexible, allowing for a more natural foot movement and better feel for the terrain.

Maintaining the Classic "Panama" Outsole

One feature that proved its worth was the M1966's "Panama style" outsole. This design, with its aggressive, wide-spaced lugs, is excellent at shedding mud and maintaining grip. The JCB wisely retains this classic pattern.

Enhancing Environmental Performance

A key focus of the redesign was improving how the boot performs in its intended wet and humid environment.

Superior Water Drainage

While the M1966 had drainage eyelets, the JCB improves upon this system significantly. It features additional, better-placed drainage holes and an improved water-draining insert (insole) to expel water much more efficiently.

Increased Breathability

The JCB utilizes a breathable lining and more modern upper materials. This, combined with the enhanced drainage, allows the boot and the soldier's foot to dry substantially faster, which is critical for preventing fungal infections, trench foot, and blisters.

Understanding the Trade-offs and Design Philosophy

It's crucial to understand this isn't just an update but a reflection of a different approach to soldier equipment.

From Simple Toughness to Performance

The M1966 was a product of 1960s manufacturing. Its goal was mass-producible, simple toughness. The boot was expected to endure, but little consideration was given to the long-term physical toll on the wearer.

A Focus on the Human Factor

The JCB prioritizes the human factor. By reducing weight, increasing flexibility, and absorbing shock, the boot is designed to keep the modern warfighter more effective and less injury-prone over long periods. It acknowledges that operator longevity is a key component of mission success.

Ergonomics and Agility

Additional features like a lower heel height to prevent snagging on vines, a redesigned upper for a more anatomical fit, and speed laces all point to a focus on agility, comfort, and ease of use in high-stress situations.

Key Upgrades for the Modern Operator

Your evaluation of the boot depends on your specific performance priorities.

- If your primary focus is injury prevention: The addition of the shock-absorbing midsole and the move from a rigid steel plate to a flexible ballistic fabric are the most critical upgrades.

- If your primary focus is performance in wet environments: The enhanced drainage system and modern breathable materials offer a dramatic improvement in drying time and foot health.

- If your primary focus is agility and comfort: The lighter materials, more ergonomic upper, and lower heel height combine to create a boot that is far less fatiguing to wear.

Ultimately, the new Jungle Combat Boot leverages 50 years of material and design advancements to create a platform that better protects its most valuable component: the soldier wearing it.

Summary Table:

| Feature | M1966 Vietnam-Era Boot | New Jungle Combat Boot (JCB) |

|---|---|---|

| Sole Cushioning | Solid rubber, no shock absorption | Shock-absorbing polymer foam midsole |

| Puncture Protection | Heavy, rigid steel plate | Lightweight, flexible ballistic fabric |

| Water Drainage | Basic drainage eyelets | Enhanced drainage system with better-placed holes |

| Breathability | Limited | Modern breathable lining & materials |

| Design Focus | Simple durability | Operator performance, injury prevention, agility |

Ready to Equip Your Team with Advanced Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of tactical, safety, and outdoor boots designed with the latest materials and ergonomic principles.

Let us help you source or develop the perfect boot for your operational needs. Contact our experts today to discuss your requirements and discover how we can enhance your product line.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

People Also Ask

- Why has Cordura remained relevant despite new fabrics? The Unbeatable Balance of Durability & Comfort

- What are the limitations of combat boots? Understanding the Trade-offs of Rugged Footwear

- How can a shiny finish be achieved on military boots? A Step-by-Step Guide to a Mirror Shine

- How do tactical boots and combat boots compare in breathability? Tactical Boots Offer Superior Airflow

- How do luxurious ostrich leather shoes differ from traditional dress shoes? A Guide to Texture & Comfort