In short, these boots are constructed from velour leather and textile for the upper portion, with a sole made of polyurethane. This specific combination of materials is chosen to create a boot that prioritizes flexibility, light weight, and immediate comfort over rugged, all-weather durability.

Understanding the materials used in a boot is the key to understanding its intended purpose. The choice of velour leather, textile, and polyurethane points to a design focused on comfort and breathability for light-duty or urban environments, not for harsh, demanding conditions.

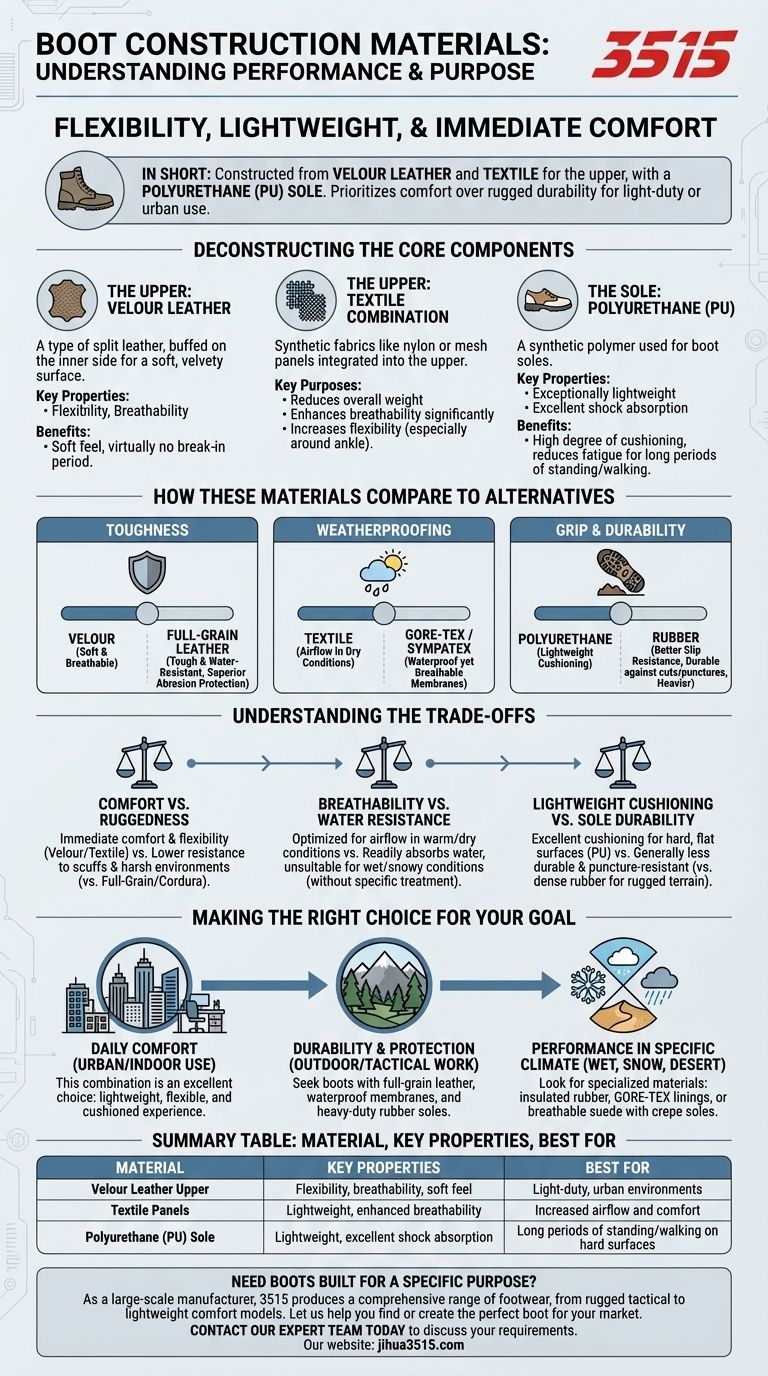

Deconstructing the Core Components

To grasp what these boots offer, we need to analyze each material's inherent properties and how they function together as a system.

The Upper: Velour Leather

Velour leather is a type of split leather, similar to suede, that is buffed on the inner side to create a soft, velvety surface.

Its primary characteristics are flexibility and breathability. Unlike the smooth, tough exterior of full-grain leather, velour provides a softer feel that requires virtually no break-in period.

The Upper: Textile Combination

The term "textile" in this context typically refers to synthetic fabrics like nylon or mesh panels integrated into the boot's upper.

This material serves several key purposes. It reduces the overall weight of the boot, enhances breathability significantly, and increases flexibility, especially around the ankle.

The Sole: Polyurethane (PU)

Polyurethane is a synthetic polymer used widely for boot soles, prized for its unique balance of properties.

PU soles are known for being exceptionally lightweight and excellent at shock absorption. This provides a high degree of cushioning and comfort, reducing fatigue during long periods of standing or walking.

How These Materials Compare to Alternatives

The choice of velour, textile, and polyurethane becomes clearer when contrasted with materials used in more specialized boots.

Toughness: Velour vs. Full-Grain Leather

Duty and police boots often use full-grain leather, which is the toughest and most water-resistant type of leather. While velour is soft and breathable, full-grain leather offers superior protection and durability against abrasion and moisture.

Weatherproofing: Textile vs. GORE-TEX

High-performance tactical boots often incorporate waterproof yet breathable membranes like GORE-TEX or Sympatex. The textile in these boots is designed for airflow in dry conditions, not for keeping water out.

Grip and Durability: Polyurethane vs. Rubber

Many police, desert, and snow boots feature soles made of rubber. Rubber typically offers better slip resistance and is more durable against cuts and punctures than polyurethane, but at the cost of being significantly heavier.

Understanding the Trade-offs

No boot can excel in every category. The materials used in this boot represent a clear set of design choices and compromises.

Comfort vs. Ruggedness

The combination of velour leather and textile panels makes the boot immediately comfortable and flexible. The trade-off is a lower resistance to scuffs, tears, and harsh environments compared to a boot made of full-grain leather or heavy-duty nylon like Cordura.

Breathability vs. Water Resistance

This boot's construction is optimized for airflow, making it comfortable in warm or dry conditions. However, both velour leather and standard textiles will absorb water readily, making them unsuitable for wet or snowy environments without specific waterproof treatment.

Lightweight Cushioning vs. Sole Durability

The polyurethane sole provides excellent cushioning, making it ideal for walking on hard, flat surfaces like pavement. It is, however, generally less durable and puncture-resistant than a dense rubber sole designed for rugged, unpredictable terrain.

Making the Right Choice for Your Goal

Ultimately, the effectiveness of these materials depends entirely on your intended use.

- If your primary focus is daily comfort for urban or indoor use: This material combination is an excellent choice, offering a lightweight, flexible, and cushioned experience.

- If your primary focus is durability and protection for outdoor or tactical work: You should seek boots made from full-grain leather, waterproof membranes, and heavy-duty rubber soles.

- If your primary focus is performance in a specific climate (wet, snow, desert): Look for boots with specialized materials like insulated rubber, GORE-TEX linings, or breathable suede with crepe soles.

By aligning a boot's materials with your specific needs, you ensure it will perform exactly as you expect it to.

Summary Table:

| Material | Key Properties | Best For |

|---|---|---|

| Velour Leather Upper | Flexibility, breathability, soft feel | Light-duty, urban environments |

| Textile Panels | Lightweight, enhanced breathability | Increased airflow and comfort |

| Polyurethane (PU) Sole | Lightweight, excellent shock absorption | Long periods of standing/walking on hard surfaces |

Need boots built for a specific purpose?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots—from rugged, full-grain leather tactical boots to lightweight, comfort-focused models.

Let us help you find or create the perfect boot for your market.

Contact our expert team today to discuss your specific requirements and discover how we can deliver quality, comfort, and durability at scale.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Durable & Breathable Training Shoes for Custom Brands

People Also Ask

- What is the connection between desert boots and South African footwear? From Veldskoen to Global Icon

- What is the primary purpose of military boots? Ensuring Protection, Support, and Performance

- How often should military boots be cleaned? Maintain Peak Performance & Longevity

- Why is it important to wear proper boots when riding a motorcycle? Essential Protection for Every Rider

- What is the distinction between issued boots and Optional Boots? Choosing the Right Footwear for Military Standards

- Why are slip-resistant military boots important? The Foundation of Soldier Safety and Mission Success

- What were the early developments of jungle boots before World War II? From Panama to Proven Design

- Why did Australian soldiers prefer American jungle boots in Vietnam? A Lesson in Survival-Focused Design