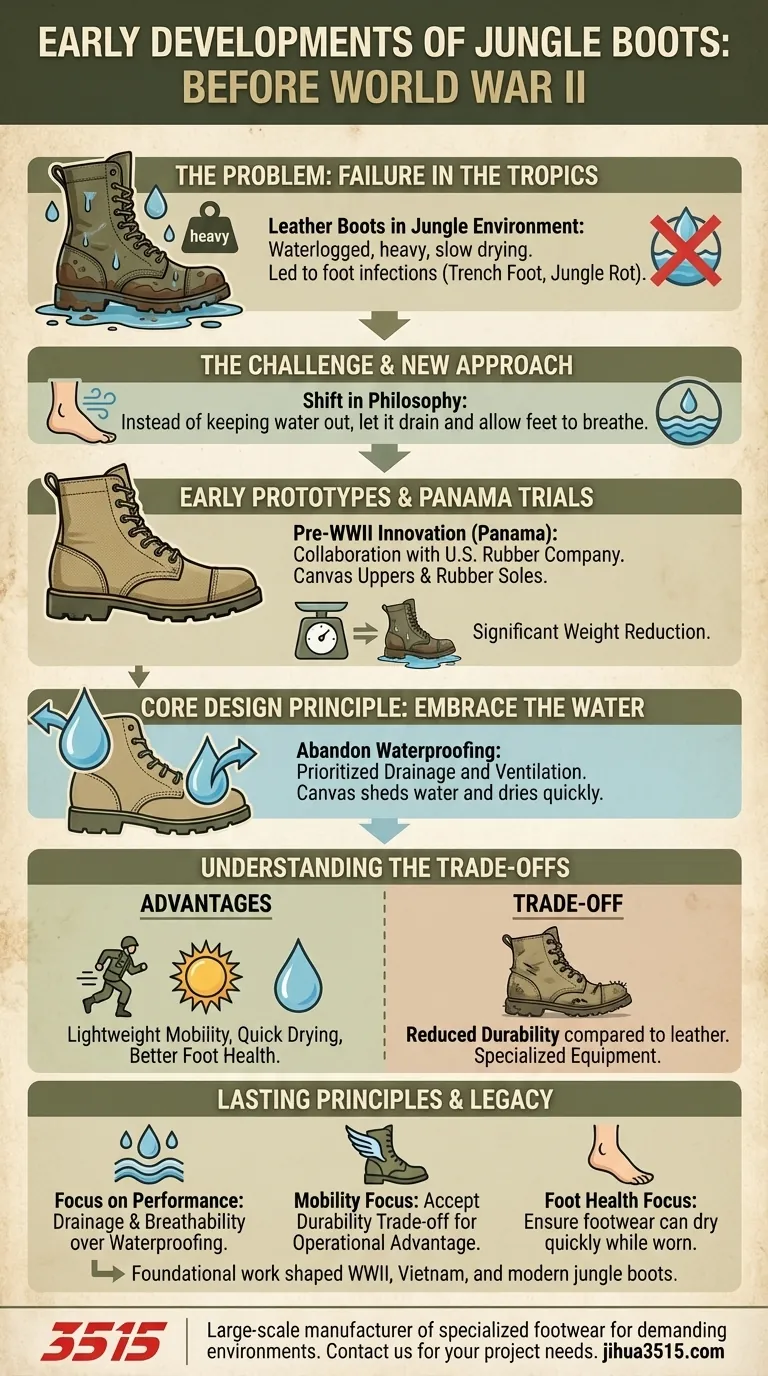

The earliest development of jungle boots began before World War II, driven by the unique challenges faced by U.S. soldiers operating in the tropical environment of Panama. These experimental boots, created in partnership with the U.S. Rubber Company, used a combination of canvas uppers and rubber soles, establishing a design philosophy that would define this type of footwear for decades.

The core innovation of the pre-war jungle boot was a radical shift in thinking: instead of attempting to keep water out, the design focused on letting water drain and allowing the foot to breathe and dry quickly.

The Problem: Why Traditional Boots Failed in the Tropics

The Failure of Leather

Standard-issue military boots of the era were made of heavy leather. While durable in temperate climates, they were disastrous in a jungle environment.

Once wet, leather boots become waterlogged, extremely heavy, and take days to dry. This creates the perfect conditions for debilitating foot infections, such as trench foot or jungle rot.

The Need for a New Approach

Military planners realized that a fundamentally different type of footwear was required for soldiers to remain effective in hot, swampy, and perpetually wet conditions. The goal shifted from durability and protection alone to include light weight, drainage, and rapid drying.

Early Prototypes and the Panama Trials

A New Material Philosophy: Canvas and Rubber

The solution came from abandoning leather entirely for the boot's upper. Designers turned to canvas, a light and breathable fabric that, while not waterproof, would shed water and dry relatively quickly when exposed to air.

This was paired with a rubber sole, which provided better traction in mud and wet conditions than traditional leather soles.

Testing and Key Specifications

Small units of U.S. soldiers stationed in Panama were issued these early prototypes for field testing. Developed with the U.S. Rubber Company, these initial boots weighed approximately three pounds per pair—a significant reduction compared to waterlogged leather boots.

The Core Design Principle: Embrace the Water

Abandoning Futile Waterproofing

The most critical insight from this early development was accepting the futility of trying to create a waterproof boot that could also provide ventilation. In an environment with river crossings and constant downpours, water would always get in over the top.

Prioritizing Drainage and Ventilation

The canvas upper allowed water to drain out almost as quickly as it entered. This, combined with the material's breathability, allowed air to circulate around the foot, preventing the constant moisture buildup that destroyed both the soldier's skin and the boot itself.

Understanding the Trade-offs

Reduced Durability

The primary trade-off for this new design was durability. The references note that even the later M-1942 model, based on these principles, wore out much faster than standard-issue leather field shoes. Canvas simply could not withstand the same level of abuse as thick leather.

Specialized, Not General-Purpose

Because of their faster wear, these boots were not seen as a replacement for standard footwear but as specialized equipment. During WWII, troops often carried them as a secondary pair specifically for navigating the deep mud and swamps where their advantages were most pronounced.

Lasting Principles from Early Development

The foundational work done in Panama before the war directly shaped the iconic jungle boots of WWII, Vietnam, and beyond. The core principles remain highly relevant.

- If your primary focus is performance in hot, wet environments: Prioritize drainage and breathability over waterproofing.

- If your primary focus is lightweight mobility: Accept a potential trade-off in long-term durability for immediate operational advantage.

- If your primary focus is foot health in the tropics: Ensure footwear can dry as quickly as possible, even while being worn.

This pre-war shift in design philosophy was a crucial innovation that recognized the environment as the true challenge to overcome.

Summary Table:

| Development Phase | Key Innovation | Primary Challenge Solved |

|---|---|---|

| Pre-WWII (Panama Trials) | Canvas uppers & rubber soles | Rapid drying & foot health in perpetually wet conditions |

| Design Philosophy | Prioritized drainage over waterproofing | Prevented trench foot and jungle rot |

| Trade-off | Lighter weight and better mobility | Reduced long-term durability compared to leather |

Need durable, specialized footwear for demanding environments?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including modern iterations built on the proven principles of breathability and quick-drying performance.

Contact our team today to discuss your specific needs and leverage our expertise for your next project.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What are the advantages of rubber soles in safety boots? Unbeatable Grip & Durability

- How can footwear sole technology be upgraded to prevent entrapment risks? Engineering Safe, Anti-Snap Designs

- Why is rubber commonly used for non-slip soles? The Science of Superior Grip

- Why are rubber soles beneficial in cold-weather boots? Superior Traction & Waterproofing

- What types of work environments are hiker-style rubber outsoles best for? Ideal for Outdoor & Industrial Safety