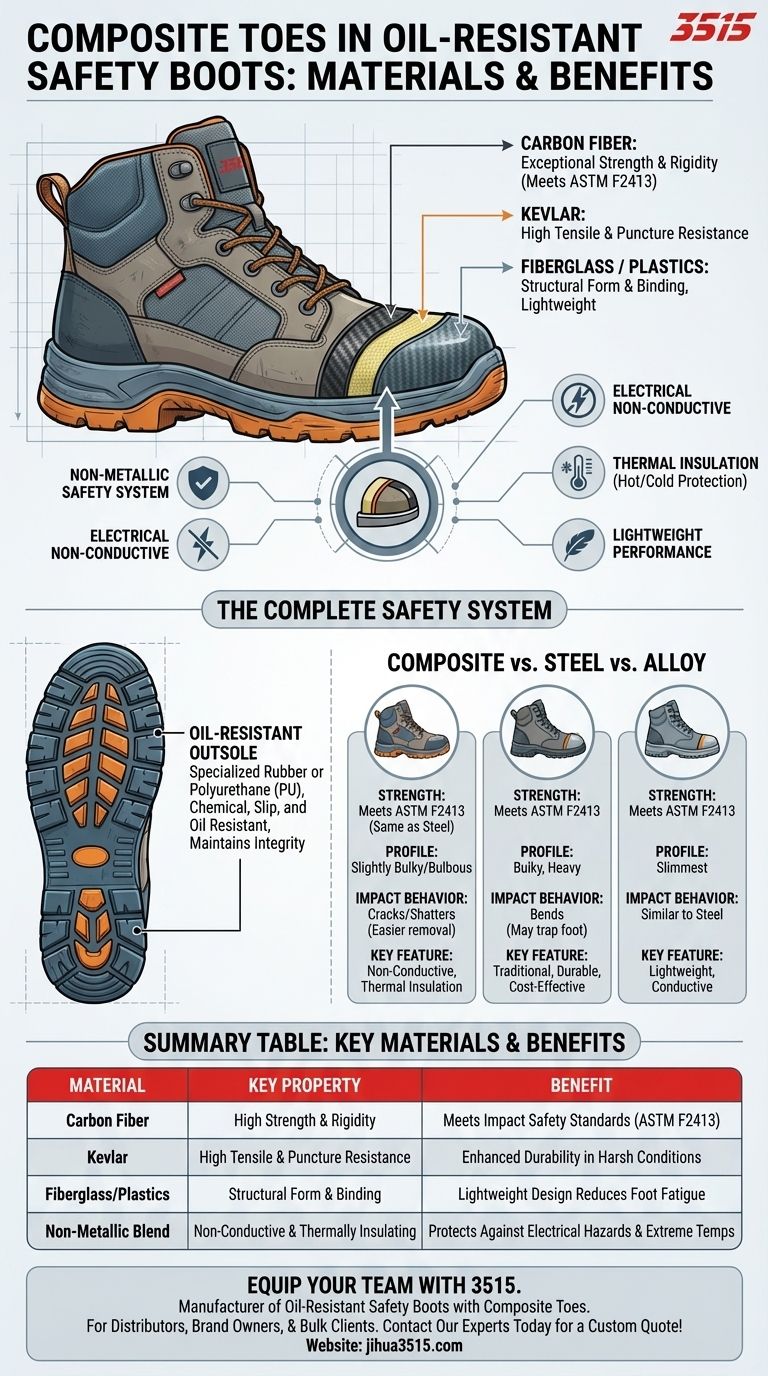

At their core, composite safety toes are constructed from a blend of non-metallic materials. The most common components used are carbon fiber, Kevlar, specialized plastics, and fiberglass, which are layered and bonded together to create a protective cap.

The crucial insight is that composite toes are not about a single material, but about creating a non-metallic safety system. This design provides impact protection equivalent to steel while eliminating electrical conductivity and thermal transfer, making them ideal for hazardous work environments where oil resistance is also a key requirement.

What "Composite" Really Means

A composite toe cap is an engineered safety component designed to replace traditional steel toes. Its primary advantage comes from being completely free of metal, which introduces several critical safety and comfort benefits.

The Key Ingredients

The term "composite" refers to the combination of materials. Each element is chosen for a specific property: carbon fiber provides exceptional strength and rigidity, Kevlar offers high tensile strength and puncture resistance, and plastics or fiberglass are used to create the structural form and bind the layers.

The Non-Metallic Advantage

By avoiding metal, composite toes do not conduct electricity. This makes them essential for electricians or anyone working in environments with a risk of electrical shock. This property is a fundamental reason they are often specified for boots used in industrial settings like oil refineries.

Lightweight Performance

A significant benefit of this material blend is a reduction in weight compared to steel. This decreases foot fatigue over a long workday, which is a critical factor for comfort and overall worker endurance without compromising on mandated safety standards.

The Complete Safety System: Beyond the Toe

It's important to understand that the composite toe is one part of a larger safety system. While the toe cap protects against impact, the "oil-resistant" quality of the boot comes from other components.

The Role of the Outsole

The boot's resistance to oil, chemicals, and slipping is determined by the outsole. This part of the boot is typically made from specialized rubber or polyurethane (PU) compounds designed to maintain their integrity and grip even when exposed to corrosive substances.

Protection from Temperature Extremes

Unlike steel, composite materials are poor conductors of heat and cold. This means the toe area of the boot remains more comfortable in extreme temperatures, protecting the wearer from environmental discomfort and potential cold-related injuries.

Composite vs. Steel: The Critical Trade-offs

While composite toes offer many advantages, it's crucial to understand their trade-offs compared to traditional steel or modern alloy toes to make an informed decision.

The Myth of Weaker Protection

A common misconception is that composite toes are weaker than steel. This is incorrect. To be sold as safety footwear, all composite toe boots must meet the same ASTM International standard (ASTM F2413) for impact and compression resistance as their steel counterparts.

The Bulk Factor

To achieve the same level of strength as steel, a composite toe cap often needs to be slightly thicker and bulkier. This can result in a more "bulbous" toe box, which may affect the fit and style of the boot. Lighter-weight alloy toes (like aluminum or titanium) often offer the slimmest profile.

Performance After Impact

One critical difference is behavior after a severe impact. A steel toe may bend but remain intact, potentially trapping the foot. A composite toe is more likely to crack or shatter upon an impact that exceeds its safety rating, but this can make it easier to remove the boot afterward.

How to Apply This to Your Purchase

Choosing the right safety toe depends entirely on the hazards of your specific work environment.

- If your primary focus is electrical hazard protection: A composite toe is the only acceptable choice, as it is non-conductive.

- If your primary focus is working in extreme hot or cold temperatures: A composite toe will provide superior thermal insulation and comfort.

- If your primary focus is achieving the slimmest possible boot profile: An alloy toe may be a better fit, but you will lose the non-conductive benefits.

- If your primary focus is general impact protection at a lower cost: Both steel and composite meet the same safety standards, so your choice can be based on weight, comfort, and other required features like oil resistance.

Ultimately, understanding the materials allows you to select footwear that protects you not just from impact, but from all the potential risks of your job.

Summary Table:

| Composite Toe Material | Key Property | Benefit in Oil-Resistant Boots |

|---|---|---|

| Carbon Fiber | High Strength & Rigidity | Meets impact safety standards (ASTM F2413) |

| Kevlar | High Tensile & Puncture Resistance | Enhanced durability in harsh conditions |

| Fiberglass/Plastics | Structural Form & Binding | Lightweight design reduces foot fatigue |

| Non-Metallic Blend | Non-Conductive & Thermally Insulating | Protects against electrical hazards and extreme temperatures |

Ready to equip your team with superior safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of oil-resistant safety boots with composite toes for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, compliant, and comfortable footwear tailored to your specific industrial needs.

Contact our experts today to discuss your requirements and get a custom quote!

Visual Guide

Related Products

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Is composite toe as safe as steel toe? Yes, and here's why it might be the smarter choice.

- Why is the application of shock-absorbing materials in safety shoe soles necessary for shipyard workers? Vital Protection

- Why are safety shoes mandatory for historical stone cleaning? Essential Gear for Restoration Projects

- What percentage of workplace accident wounds are foot injuries? The Critical 7% and How to Prevent Them

- What role does blockchain play in footwear supply chain transparency? Enhance Safety Shoe Traceability and Verification

- How do professional safety shoes function in industrial machining? Key Engineering for Maximum Workplace Protection

- Are there vegan firefighter boots available? Yes, NFPA-Certified & High-Performance

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection