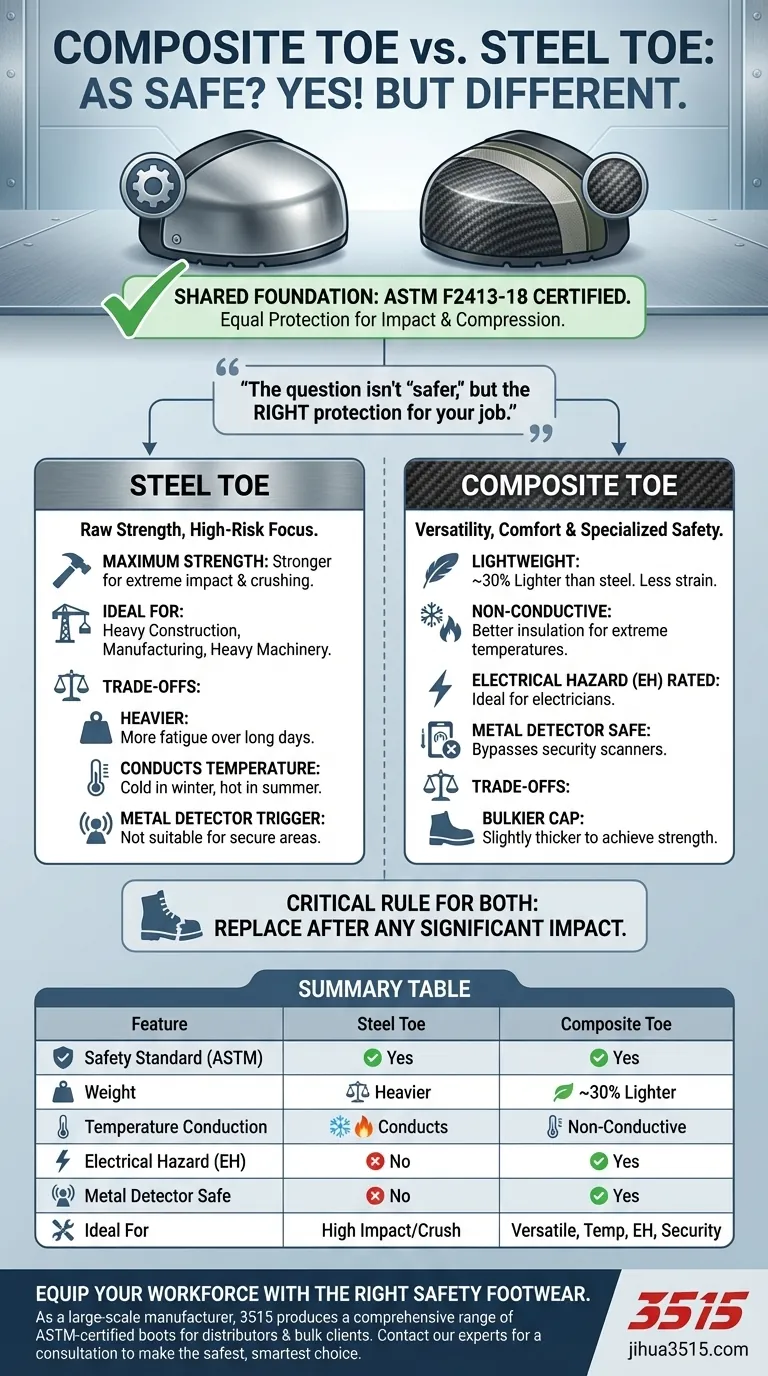

Yes, composite toe boots are considered as safe as steel toe boots. Both types must pass the exact same ASTM F2413-18 safety standards for impact and compression resistance to be sold as protective footwear. The key difference lies not in their baseline safety rating, but in the specific advantages and trade-offs each material offers for different work environments.

The question isn't whether one is "safer" than the other, but which material provides the right type of protection for your specific job. Steel offers the absolute maximum strength, while composite provides versatile, lightweight protection against a wider range of environmental hazards.

The Foundation of Safety: The ASTM Standard

Passing the Same Test

At their core, both steel and composite toe boots are designed to protect your feet from the same primary threats: sudden impacts and slow compression (crushing forces).

To be certified, all safety footwear must meet the requirements of the ASTM F2413-18 standard. This means a composite toe boot has been tested and proven to withstand the same level of impact and compression as its steel toe counterpart.

Where Steel Toe Excels: Raw Strength

The Strongest Protection

Steel is inherently stronger and more durable than composite materials. This means it offers the highest possible level of protection against extreme impact and crushing hazards.

For this reason, steel toes are often the preferred choice in high-risk industries like heavy construction, manufacturing, and work environments involving heavy machinery.

The Trade-off: Weight and Conduction

This superior strength comes at a cost. Steel toe caps are heavier than composite, which can lead to greater fatigue over a long workday.

Because steel is metal, it readily conducts temperature. In very cold conditions, the steel can draw heat away from your feet, and in hot environments, it can become uncomfortably warm.

The Advantages of Composite Toe: Versatility and Comfort

Significant Weight Reduction

Composite safety toes are made from non-metallic materials like carbon fiber, plastic, or Kevlar. They are approximately 30% lighter than steel toes.

This significant weight difference makes composite toe boots more comfortable for long shifts, reducing strain and fatigue on your legs and back.

Protection from the Elements

Unlike metal, composite materials do not conduct heat or cold. This makes them far superior for working in extreme temperatures.

They provide better insulation, keeping your feet warmer in the cold and cooler in the heat, which is a major factor in both comfort and safety.

Electrical Hazard (EH) Safety

Because they are non-metallic, composite toes are non-conductive. This makes them the ideal choice for electricians or anyone working in environments with a risk of live electrical hazards.

Bypassing Metal Detectors

The non-metallic nature of composite toes means they won't set off metal detectors. This is a critical advantage for workers in security, airports, or other secured facilities who must pass through scanners frequently.

Understanding the Trade-offs

Strength vs. Bulk

While composite toes pass the same safety standards as steel, they are not as strong in an absolute sense. To achieve the required level of protection, composite caps often need to be slightly thicker or bulkier than steel caps.

Durability After an Impact

It is a critical rule for all safety footwear: any boot that has sustained a significant impact must be replaced. The protective integrity of the toe cap—whether steel or composite—is compromised after it has done its job once.

Choosing the right boot isn't about picking the "safest" option, but the smartest one for the specific hazards you face every day.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Safety Standard | Meets ASTM F2413-18 | Meets ASTM F2413-18 |

| Weight | Heavier | ~30% Lighter |

| Temperature Conduction | Conducts heat/cold | Non-conductive, better insulation |

| Electrical Hazard (EH) Rated | No | Yes |

| Metal Detector Safe | No | Yes |

| Ideal For | Extreme impact/crush hazards | Versatile use, extreme temperatures, electrical work |

Ready to equip your workforce with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified steel toe and composite toe boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, ensuring you get durable, comfortable, and compliant boots tailored to your specific industry hazards.

Contact our experts today for a consultation and let us help you make the safest, smartest choice for your team.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job