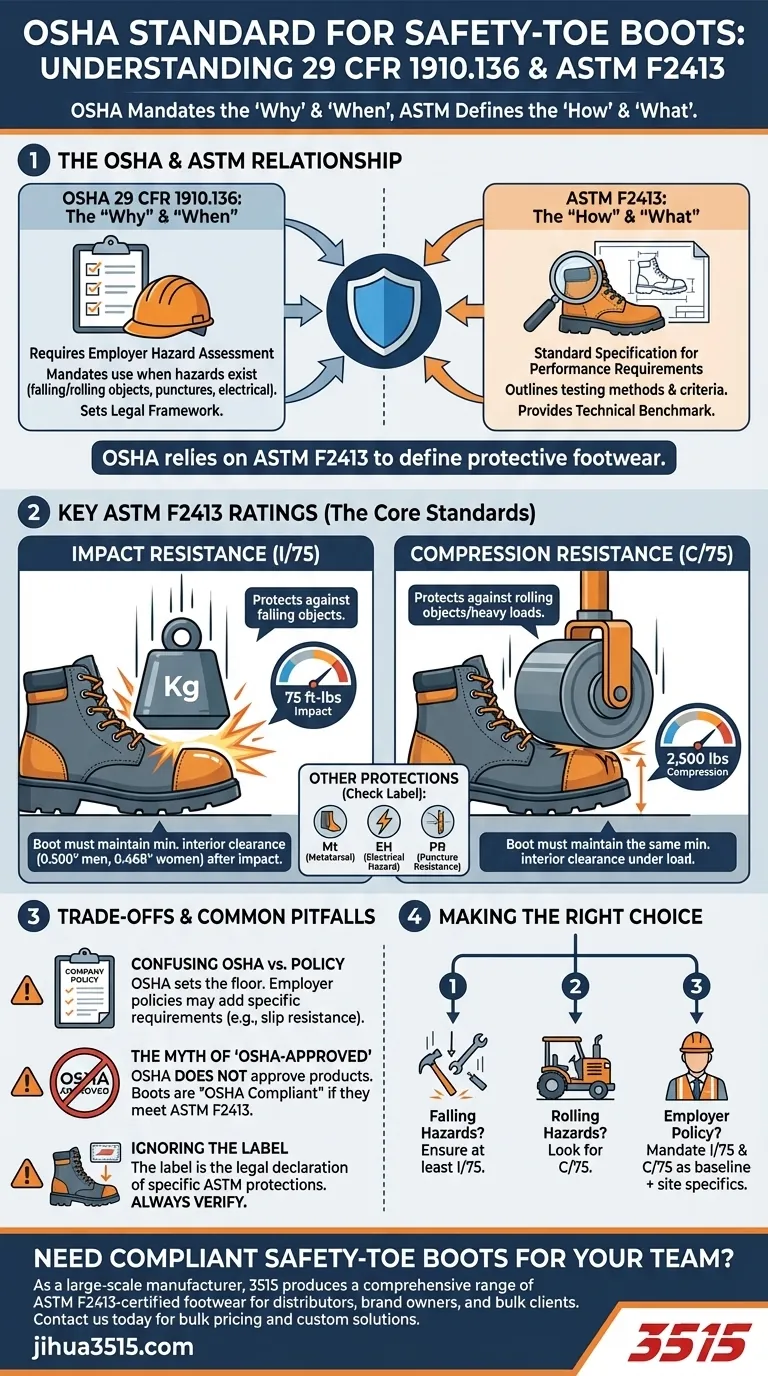

The core OSHA standard for protective footwear is 29 CFR 1910.136. However, this OSHA standard does not set its own detailed performance specifications. Instead, it mandates that employers ensure protective footwear is used when necessary and that this footwear complies with the technical requirements of a recognized consensus standard, most commonly ASTM F2413.

OSHA dictates when protective footwear is required based on workplace hazards, but it relies on the ASTM F2413 standard to define what makes that footwear protective. The most common rating, "I/75 C/75", protects against a 75 foot-pound impact and 2,500 pounds of compression.

Deconstructing the OSHA and ASTM Relationship

To ensure compliance and safety, it is critical to understand how these two standards work together. OSHA provides the legal framework, while ASTM provides the technical benchmark.

OSHA's Role: The "Why" and "When"

OSHA standard 1910.136 requires employers to perform a hazard assessment of their workplace.

If that assessment reveals a danger of foot injuries from falling objects, rolling objects, items piercing the sole, or electrical hazards, the employer must require employees to use protective footwear.

OSHA's role is to mandate the use of this gear, but it delegates the "how-to" of construction and testing to technical experts.

ASTM's Role: The "How"

ASTM F2413 is the "Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear."

This is the document that manufacturers use to design and test their boots. It outlines the specific methods and minimum performance criteria for a boot to be officially certified as "safety-toe."

When you see a boot labeled as ASTM F2413 compliant, it means it has passed these rigorous, standardized tests.

Understanding the Key ASTM F2413 Ratings

The label inside a safety boot will specify which ASTM criteria it meets. The most fundamental of these are for impact and compression.

Impact Resistance (I/75)

This rating signifies protection against falling objects. The "75" indicates the boot has been tested to withstand an impact of 75 foot-pounds.

During the test, the boot must maintain a minimum interior clearance of 0.500 inches for men's footwear and 0.468 inches for women's footwear inside the toe cap.

Compression Resistance (C/75)

This rating signifies protection against rolling objects or heavy static loads. The "75" corresponds to a compressive force of 2,500 pounds.

Like the impact test, the boot must maintain the same minimum interior clearance (0.500" for men, 0.468" for women) under this immense load to pass.

Other Critical Protections

The ASTM standard also covers other specialized hazards, such as metatarsal protection (Mt), electrical hazard resistance (EH), and puncture resistance (PR), which will be noted on the boot's label if applicable.

Understanding the Trade-offs and Common Pitfalls

Simply knowing the standard numbers is not enough. True safety comes from understanding the practical application and potential points of failure.

Confusing OSHA with Employer Policy

OSHA sets the floor, not the ceiling. An employer's internal policy may be much more specific based on their unique environment.

For instance, a policy might require a leather upper for durability or oil-resistant soles for slip prevention. These are employer additions built upon the foundational ASTM F2413 compliance.

The Myth of "OSHA-Approved"

OSHA does not approve, certify, or endorse individual products. It sets the standard that products must meet.

A boot is "OSHA compliant" if it meets the ASTM F2413 standard that OSHA references. Be wary of any marketing that claims a boot is "OSHA-Approved."

Ignoring the Label

The single most important source of information is the label stitched inside the boot. This label is a legal declaration by the manufacturer of the specific ASTM F2413 protections the footwear provides. Always check it to verify its ratings.

Making the Right Choice for Your Goal

Use the hazard assessment for your specific role or worksite to determine the necessary level of protection.

- If your primary focus is protection from falling tools or materials: Ensure your boot is rated at least I/75, which is the highest standard ASTM impact rating.

- If your primary focus is protection from rolling equipment or heavy loads: Look for the C/75 rating, which guards against 2,500 pounds of compressive force.

- If you are an employer developing a safety policy: Mandate footwear that meets ASTM F2413 I/75 and C/75 as your baseline, then add other requirements (e.g., EH, Mt, sole type) based on your site's specific hazards.

Ultimately, matching the specific ASTM ratings on the boot's label to your workplace hazards is the key to ensuring true safety and compliance.

Summary Table:

| ASTM F2413 Rating | Hazard Protection | Test Standard |

|---|---|---|

| I/75 | Impact Resistance | Withstands 75 ft-lbs impact |

| C/75 | Compression Resistance | Withstands 2,500 lbs compression |

| EH | Electrical Hazard | Reduces electrical shock risk |

| Mt | Metatarsal Protection | Protects the top of the foot |

| PR | Puncture Resistance | Shields sole from sharp objects |

Need compliant safety-toe boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring your workforce is protected against impact, compression, and other workplace hazards.

Contact us today for bulk pricing and custom solutions tailored to your safety requirements.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the key considerations when choosing safety boots? Match Hazards to Features for Maximum Protection

- What is a safety-toe in a boot? Your Guide to Choosing the Right Protection

- What is the primary purpose of safety shoes? Your Ultimate Guide to Workplace Foot Protection

- How does routine boot maintenance benefit workplace safety? Proactive PPE Protection for Your Workforce

- What boots do they wear on oil rigs? Essential Safety Footwear for Harsh Conditions