The primary materials used in women's wellies are rubber, neoprene, and PVC. These materials are chosen for their specific performance characteristics, with the ultimate goal of providing a boot that is waterproof, durable, and suited to its intended environment, whether that's a garden, a festival, or a demanding worksite.

The ideal material for a welly isn't a one-size-fits-all answer. The choice is a deliberate trade-off between absolute waterproofing, insulation, flexibility, and durability, directly tied to how you plan to use the boots.

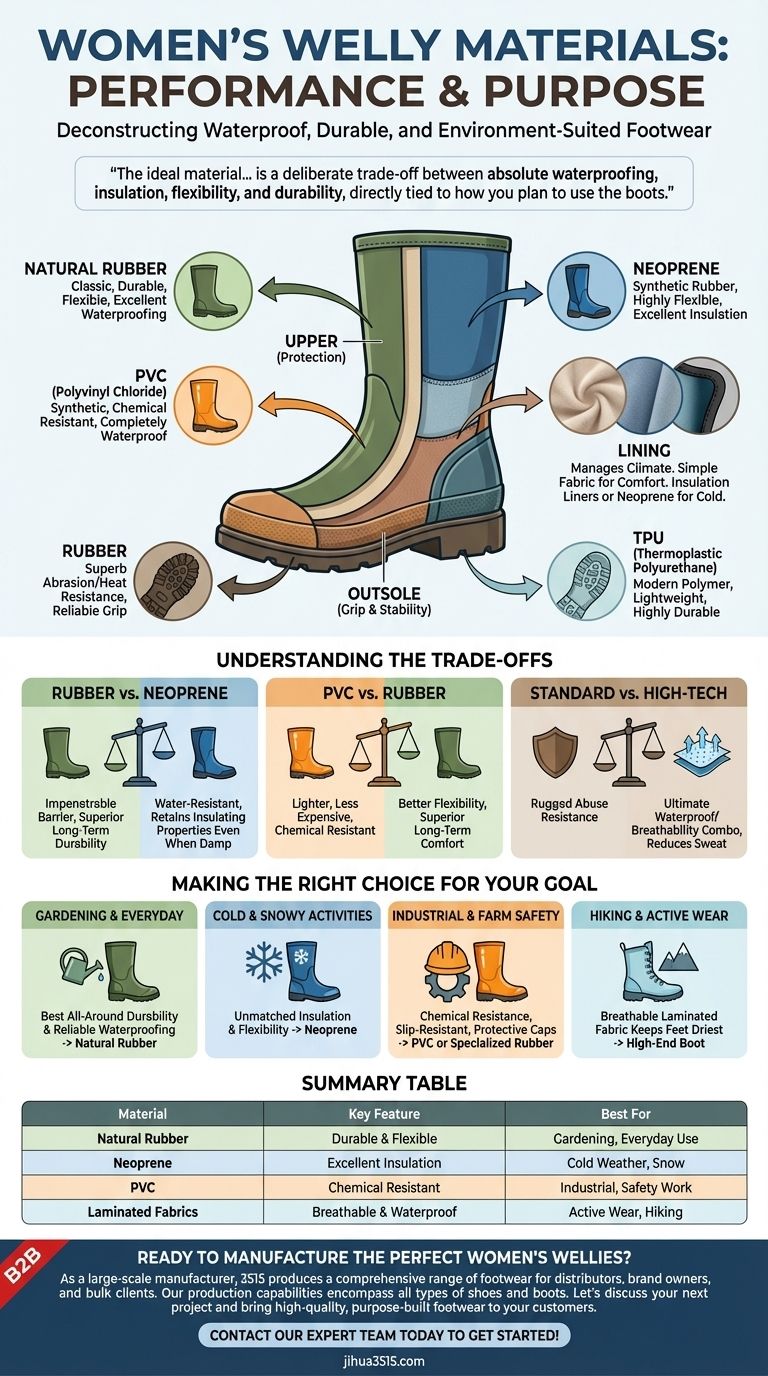

Deconstructing the Welly: Key Materials Explained

A welly is more than just a single piece of material. Understanding its core components—the upper, lining, and outsole—is crucial to grasping why different materials are used.

The Upper: Your First Line of Defense

The upper is the main body of the boot and provides the primary protection from the elements.

- Natural Rubber: This is the classic, traditional material for wellies. It is highly durable, flexible, and offers excellent natural waterproofing and wear resistance.

- PVC (Polyvinyl Chloride): A synthetic plastic alternative to rubber. It is completely waterproof and often chosen for safety wellies due to its high resistance to chemicals, acids, and alkalis.

- Neoprene: This is a type of synthetic rubber best known for its use in wetsuits. It offers great flexibility and, most importantly, excellent insulation, keeping your feet warm even if some moisture gets in.

The Lining: For Comfort and Insulation

While the upper keeps water out, the lining manages the climate inside the boot.

- Many wellies feature a simple fabric lining for basic comfort.

- For colder conditions, boots may include insulation liners or be constructed with neoprene uppers, which serve as both the structure and the insulating layer.

The Outsole: Grip, Stability, and Durability

The outsole is the part that hits the ground, making its material composition critical for safety and longevity.

- Rubber: The most common outsole material due to its superb abrasion resistance, heat resistance, and reliable grip on slippery surfaces.

- TPU (Thermoplastic Polyurethane): A more modern polymer that is lighter than rubber but still highly durable. It offers excellent resistance to splitting and abrasion.

Understanding the Trade-offs

Choosing the right welly means balancing competing material benefits. No single material is perfect for every situation.

Rubber vs. Neoprene

Rubber provides an impenetrable waterproof barrier and superior long-term durability against scuffs and tears. Neoprene, while highly water-resistant, can absorb some moisture over time but retains its insulating properties, making it far warmer in cold and wet conditions.

PVC vs. Rubber

PVC is often lighter and less expensive than rubber, with exceptional resistance to chemical exposure. However, high-quality rubber generally offers better flexibility (reducing the risk of cracking in the cold) and superior comfort for long-term wear.

Standard Materials vs. High-Tech Laminates

Some high-end boots use layered, laminated materials like Gore-Tex. These provide the ultimate combination of waterproofing and breathability, reducing sweat buildup. The trade-off is typically higher cost and potentially lower resistance to the kind of rugged abuse that a thick rubber boot can withstand.

Making the Right Choice for Your Goal

Select your boot based on its primary purpose to ensure you get the performance you need.

- If your primary focus is casual gardening and everyday wet weather: A classic natural rubber boot offers the best all-around durability and reliable waterproofing.

- If your primary focus is warmth during cold or snowy activities: Neoprene is the superior choice for its unmatched insulation and flexibility.

- If your primary focus is safety in an industrial or farm environment: Look for safety-rated wellies made from PVC or specialized rubber with slip-resistant outsoles and protective toe caps.

- If your primary focus is comfort during long hikes or active wear: A high-end boot with a breathable laminated fabric will keep your feet driest from both rain and sweat.

Understanding these core materials empowers you to choose a welly that is a true tool for your needs.

Summary Table:

| Material | Key Feature | Best For |

|---|---|---|

| Natural Rubber | Durable & Flexible | Gardening, Everyday Use |

| Neoprene | Excellent Insulation | Cold Weather, Snow |

| PVC | Chemical Resistant | Industrial, Safety Work |

| Laminated Fabrics | Breathable & Waterproof | Active Wear, Hiking |

Ready to manufacture the perfect women's wellies?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the right combination of materials, durability, and style for your market.

Let's discuss your next project and bring high-quality, purpose-built footwear to your customers.

Contact our expert team today to get started!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How does the lightweight nature of PVC boots benefit workers? Reduce Fatigue & Prevent Injury

- What are the disadvantages of Wellington boots? Key Downsides in Ergonomics and Comfort

- What role does the sole play in Wellington boots? It's the Engineered Foundation for Safety & Comfort

- Should I size up when buying Wellington boots? Get the Perfect Fit for Comfort & Safety

- What are the environmental issues with modern Wellington boots? The Hidden Cost of PVC

- What are the different types of wellies available? Choose the Right Boot for Every Occasion

- Does the lining of Wellington boots affect their size? A Guide to Finding the Perfect Fit

- What are the benefits and drawbacks of neoprene-lined wellington boots? A Guide to Cold-Weather Footwear