The primary disadvantages of Wellington boots are poor ergonomic support, lack of breathability, and weight. While they offer superior waterproofing, their loose fit often compromises ankle stability, making them unsuitable for traversing rough terrain or walking long distances. Furthermore, the impermeable materials used in their construction can lead to moisture buildup from perspiration, causing discomfort and temperature regulation issues in both hot and cold environments.

While Wellington boots provide an impenetrable barrier against water and mud, they sacrifice mechanical support and thermal regulation to do so. They are best viewed as specialized stationary protection rather than performance footwear for dynamic movement.

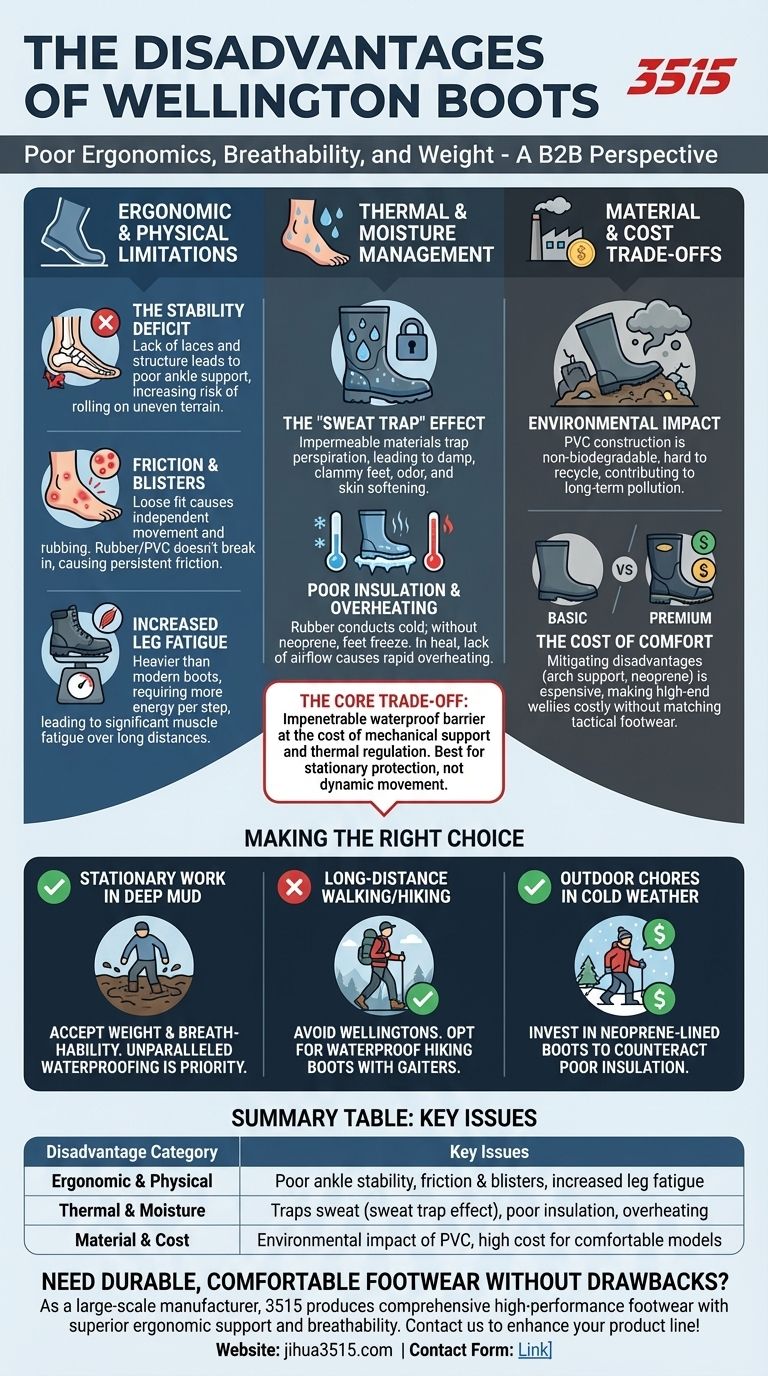

Ergonomic and Physical Limitations

The Stability Deficit

Standard Wellington boots lack the laces and structural rigidity found in hiking or tactical boots. Because they do not hug the ankle or instep, your foot is prone to sliding inside the boot.

This "slop" in the fit significantly reduces stability. On uneven ground, this increases the risk of rolling an ankle or losing your balance.

Friction and Blisters

The loose fit often creates friction points as the foot moves independently of the boot. During long walks, this constant rubbing against the heel or toes inevitably leads to blisters.

Unlike leather boots that break in and mold to your foot, rubber and PVC maintain their shape. This means the friction issues rarely improve over time.

Increased Leg Fatigue

Wellington boots are frequently heavier and bulkier than modern walking boots. The extra weight at the end of your leg increases the energy required for every step.

Over the course of a day, this added bulk leads to significant muscle fatigue. This makes them particularly inefficient for covering long distances.

Thermal and Moisture Management

The "Sweat Trap" Effect

The same impermeability that keeps water out also traps moisture inside. Materials like rubber and neoprene do not breathe, meaning perspiration cannot escape.

This leads to feet becoming damp, clammy, and prone to odor. In prolonged wear, this moisture can soften the skin, making it even more susceptible to blistering.

Poor Insulation in Standard Models

Basic Wellington boots offer very little thermal retention. The rubber construction conducts cold from the ground directly to your foot.

Without expensive neoprene linings or specialized socks, your feet will quickly become cold in winter conditions. Conversely, in warm weather, the lack of airflow causes rapid overheating.

Understanding the Trade-offs: Material and Cost

Environmental Impact

Most modern Wellingtons are manufactured from PVC (polyvinyl chloride). This material is derived from oil and is non-biodegradable.

Because PVC cannot be easily recycled, discarded boots contribute to long-term environmental pollution. This contrasts with leather footwear, which is often repairable or more biodegradable.

The Cost of Comfort

While basic wellies are cheap, mitigating their disadvantages is expensive. High-end designs that feature arch support, neoprene insulation, and Vibram soles cost significantly more.

You effectively pay a premium to make a rubber boot perform like a hiking boot. Even then, they rarely match the breathability and agility of dedicated tactical or walking footwear.

Making the Right Choice for Your Goal

To decide if the downsides of Wellington boots are acceptable for your needs, consider the primary activity you are undertaking.

- If your primary focus is stationary work in deep mud or water: Accept the weight and lack of breathability, as the unparalleled waterproof protection is your priority.

- If your primary focus is long-distance walking or hiking: Avoid Wellingtons entirely; opt for waterproof hiking boots with gaiters to ensure ankle support and breathability.

- If your primary focus is general outdoor chores in cold weather: Invest in high-end, neoprene-lined boots to counteract the lack of natural insulation found in standard rubber models.

Choose the tool that protects you not just from the elements, but from fatigue and injury.

Summary Table:

| Disadvantage Category | Key Issues |

|---|---|

| Ergonomic & Physical | Poor ankle stability, friction & blisters, increased leg fatigue |

| Thermal & Moisture | Traps sweat (sweat trap effect), poor insulation, overheating |

| Material & Cost | Environmental impact of PVC, high cost for comfortable models |

Need durable, comfortable footwear without the drawbacks?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, designed with superior ergonomic support and breathability to keep your customers comfortable and protected.

Contact us today to discuss your footwear needs and discover how we can enhance your product line!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Who popularized the Wellington boot and how did it get its name? A Story of Practical Design

- How can you prevent moisture from getting inside wellies? Keep Your Feet Dry with Proven Strategies

- What are wellington boots commonly known as and what activities are they associated with? Discover the Versatile 'Wellie'

- What are the key features of Wellington boots? Ultimate Protection for Wet & Hazardous Work

- What are the main types of linings for Wellington boots? Choose the Right Lining for Ultimate Comfort

- Why are wellies considered a good choice for winter footwear? Ultimate Protection from Slush & Snow

- What factors should be considered when finding the perfect Wellington boot size? Ensure Comfort and Performance

- What happens after the PVC rain boots are injection molded? From Raw Mold to Ready-to-Wear